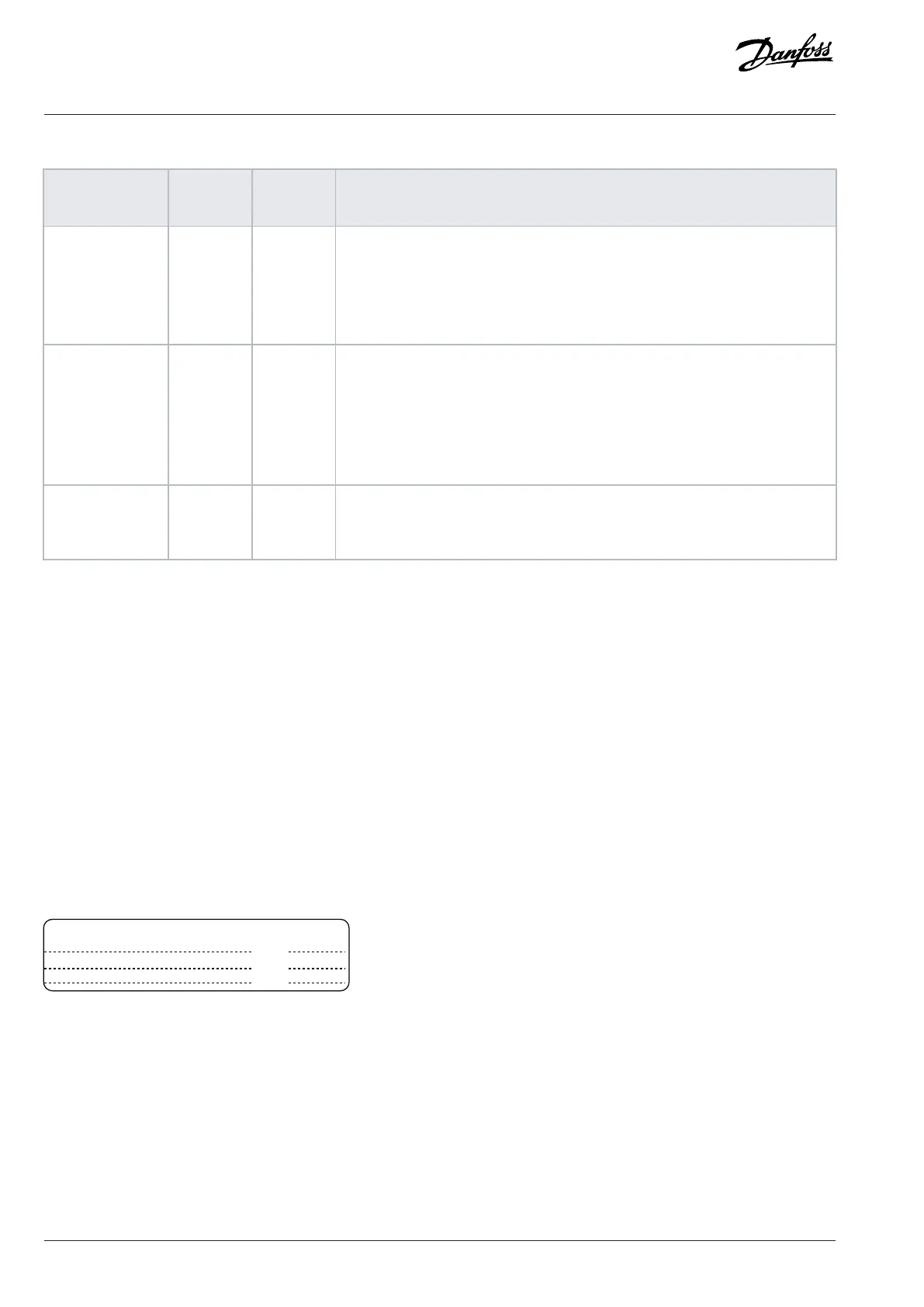

Table 42: Maintenance Schedule for Liquid-cooled Drives (continued)

Component Inspection

interval

(1)

Service

schedule

(2)

Preventive maintenance actions

Power unit heat

sinks

1 year 6 years Check that the heat sink temperature across all cooling circuits or power phases is

balanced. Imbalanced temperature of the cooling circuits is a possible sign of a re-

striction. Under normal conditions, clean or acid-wash the heat sinks every 6 years

with Danfoss recommended cleaning products. Refill the coolant system and log

the new coolant specification values.

Auxiliary equip-

ment

1 year According

to manu-

facturer

recom-

menda-

tions

Check that the sensors, gauges, and indicators are functioning correctly. Act based

on the findings.

System cooling

capacity

1 year Based on

findings

Test the cooling capacity and the thermal transfer of the system. Record the

coolant system flow, pressure, and input and output temperature, and compare to

the previous measurements. Act based on the findings.

1) Defined as the time after the commissioning/startup or the time from the previous inspection.

2) Defined as the time after the commissioning/startup or the time from the previous service schedule actions.

9.2 Maintenance Log for Cooling System

During the commissioning phase of the product and during each inspection refer to the maintenance schedule. Record values such as

the ambient air temperature, system pressure, flow, and input/output cooling liquid temperature during run condition. Record the water

chemical analysis values and the type and percentages of glycol and inhibitor or pre-mixed solutions of the liquid coolant.

The initial values create a base-line value to compare versus future values measured during preventive maintenance intervals. Record the

chemical analysis values each time the liquid coolant is replaced. Record all the maintenance tasks and service tasks with counter values,

date, and time.

9.3 Using the Product Modified Label

In the accessories bag, there is also a "product modified" label. The function of the label is to tell the service personnel about the changes

that are made in the AC drive.

P rod uc t modifie d

Date:

Date:

Figure 113: The Product Modified Label

1. Attach the label on the side of the AC drive, in a place where it is easy to find.

a. Attach the label, for example, next to the other labels on the power unit.

2. If changes are made to the AC drive, write the change and date on the label.

116 | Danfoss Drives Oy © 2024.03 AJ475942178716en-000101 / 172K2848A

Design Guide | iC7 Series Liquid-cooled System Modules

Loading...

Loading...