A Ø16/13 mm (0.63/0.51 in) tube ferrule (for example, 1827-16-13 from Parker) can be inserted into the pipe as an aid to

assess the circularity of the pipe.

6.4.7.2 Bending Pipes with a Bending Jig

These instructions were prepared with the Eiskoffer bending kit from Alphacool, but other commercial or self-made jigs can also be used.

1. Prepare the bending jig.

2. Insert the silicon cord in to the pipe and to the bending location.

It is recommended that the pipe end is at least 5 cm (2 in) from the bending area. If the bending area is too close to the

pipe end, the pipe end can become oval, which can cause the pipe and fitting joint to leak.

It is recommended to moisten the cord with distilled water to make it easier to insert into the pipe.

The cord is inserted into the pipe before it is heated, to produce equal counter pressure and to prevent the tube from

buckling. The hard pipe is easy to bend evenly with the cord inside.

3. With the cord inside, bend the pipe to the jig.

The recommended minimum bending radius >30 mm (1.18 in).

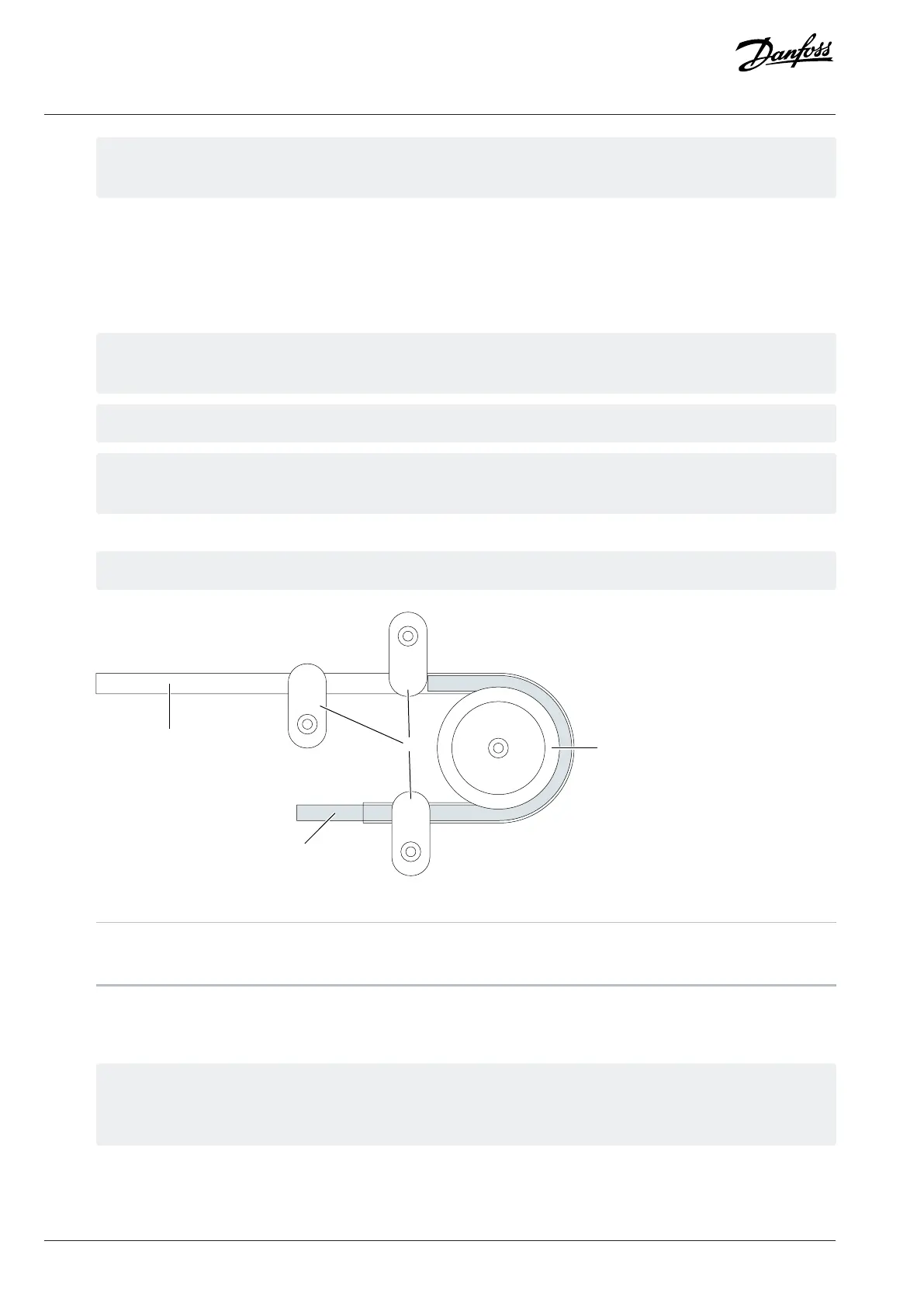

Figure 52: Pipe Bending Jig Example

1 Pipe 2 Silicon cord

3 Pipe holders 4 Bending wheel

4. Set the heat gun temperature to 200 °C (392 °F).

5. Slowly move the heat gun back and forth over the entire bending area.

The aim is to heat the pipe evenly over the entire bending area to around 150–170 °C (302–338 °F). When the pipe is heated

only at the outer edge, it takes time to heat the inner edge of the pipe as well. Therefore, the temperature used is fairly low

and, for example, when making a 180° bend with radius Ø32 mm (Ø1.26 in), the suitable heating time is 10 minutes.

58 | Danfoss Drives Oy © 2024.03 AJ475942178716en-000101 / 172K2848A

Design Guide | iC7 Series Liquid-cooled System Modules

Loading...

Loading...