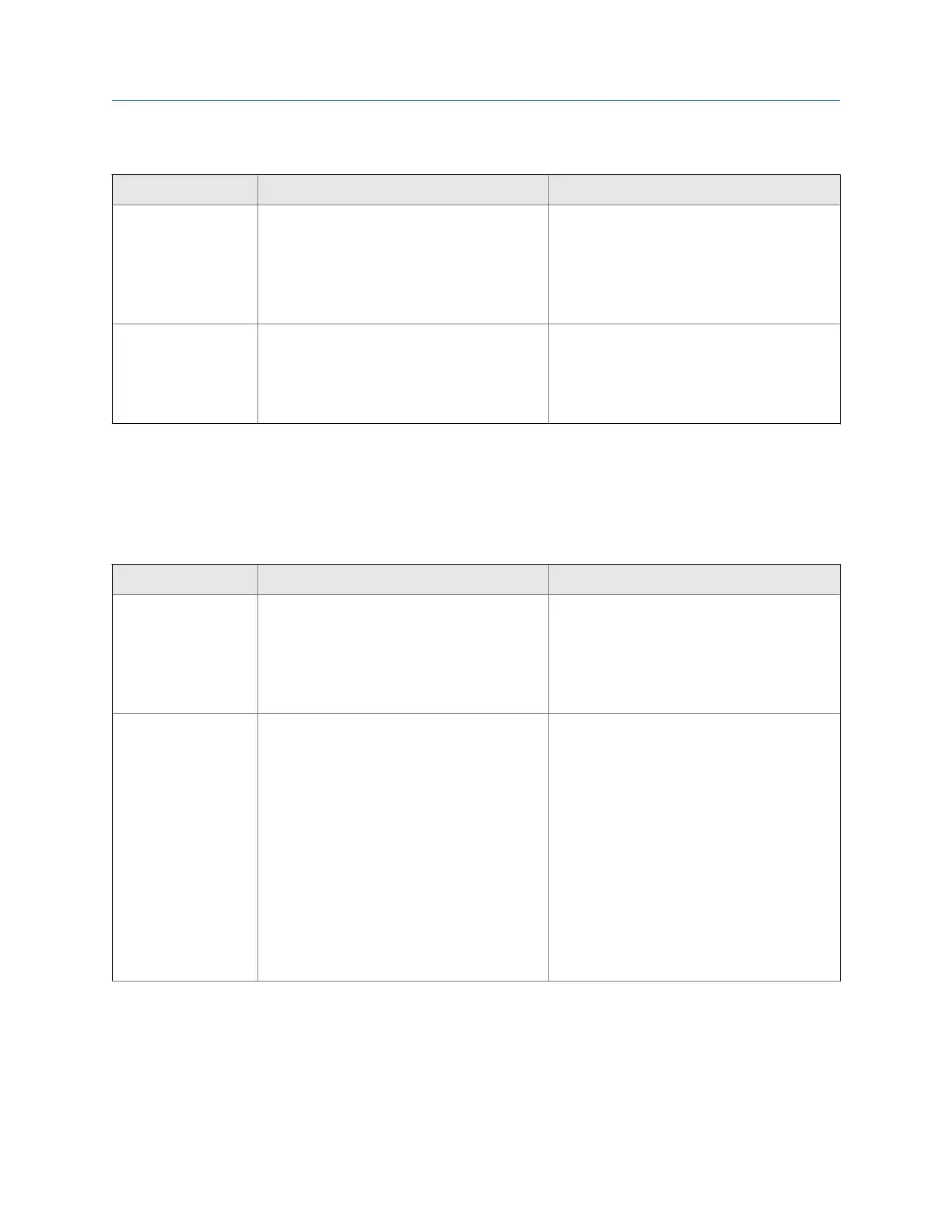

Density measurement problems and recommended actions (continued)Table 10-2:

Problem Possible causes Recommended actions

Cyclic inaccuracy in

density reading

• Stirrer rotation rate too high

• Tank flow rate too high

• Fork in poor location

• Stirrer creating bubbles

• Solids in tank

• Reduce the stirrer rotation rate.

• Reduce the tank flow rate.

• Move the fork to a location with a lower

flow profile.

• Install a sample bypass.

• Replace the device with a CDM.

Density reading from

device does not

match laboratory val-

ue

• Incorrect calibration factors

• Laboratory conditions do not match sam-

ple conditions

• Verify the calibration factors.

• Verify or adjust the density offset and/or

the density meter factor.

• Ensure that the two fluids are being com-

pared at the same temperature.

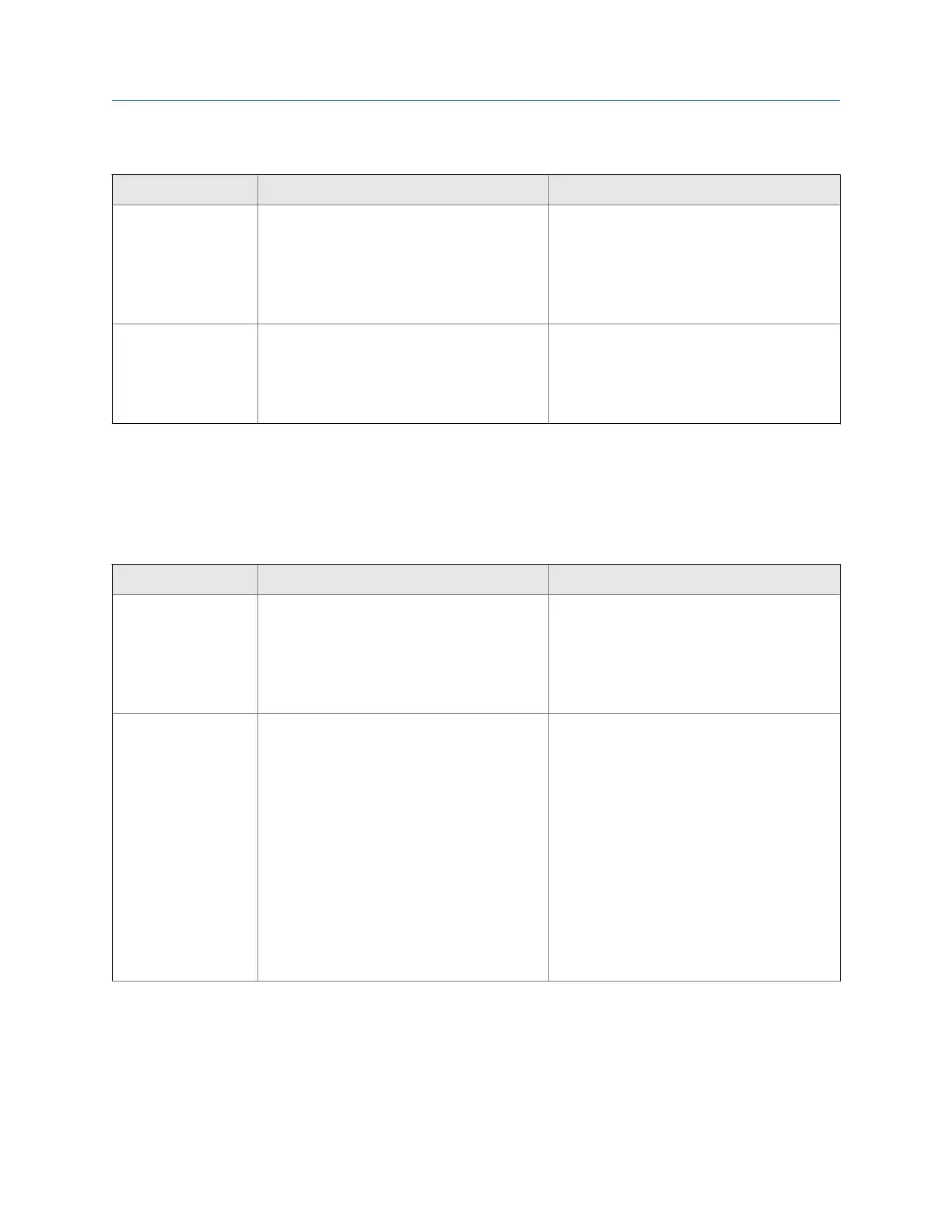

10.8 Temperature measurement problems

Temperature measurement problems and recommended actionsTable 10-3:

Problem Possible causes Recommended actions

Temperature reading

significantly different

from process temper-

ature

• RTD failure

• Incorrect compensation factors

• Line temperature in bypass does not

match temperature in main line

• Verify that the temperature compensation

factors match the value on the sensor tag

or calibration sheet.

• If Alert A004, A016, or A017 is active, per-

form the actions recommended for that

alert.

Temperature reading

slightly different from

process temperature

• Sensor temperature not yet equalized

• Sensor leaking heat

• If the error is within the temperature speci-

fication for the sensor, there is no prob-

lem. If the temperature measurement is

outside the specification, contact

Micro Motion.

• The temperature of the fluid may be

changing rapidly. Allow sufficient time for

the sensor to equalize with the process flu-

id.

• Install thermal installation, up to but not

over, the transmitter housing.

• The electrical connection between the RTD

and the sensor may be damaged. This may

require replacing the sensor.

Troubleshooting

Configuration and Use Manual 147

Loading...

Loading...