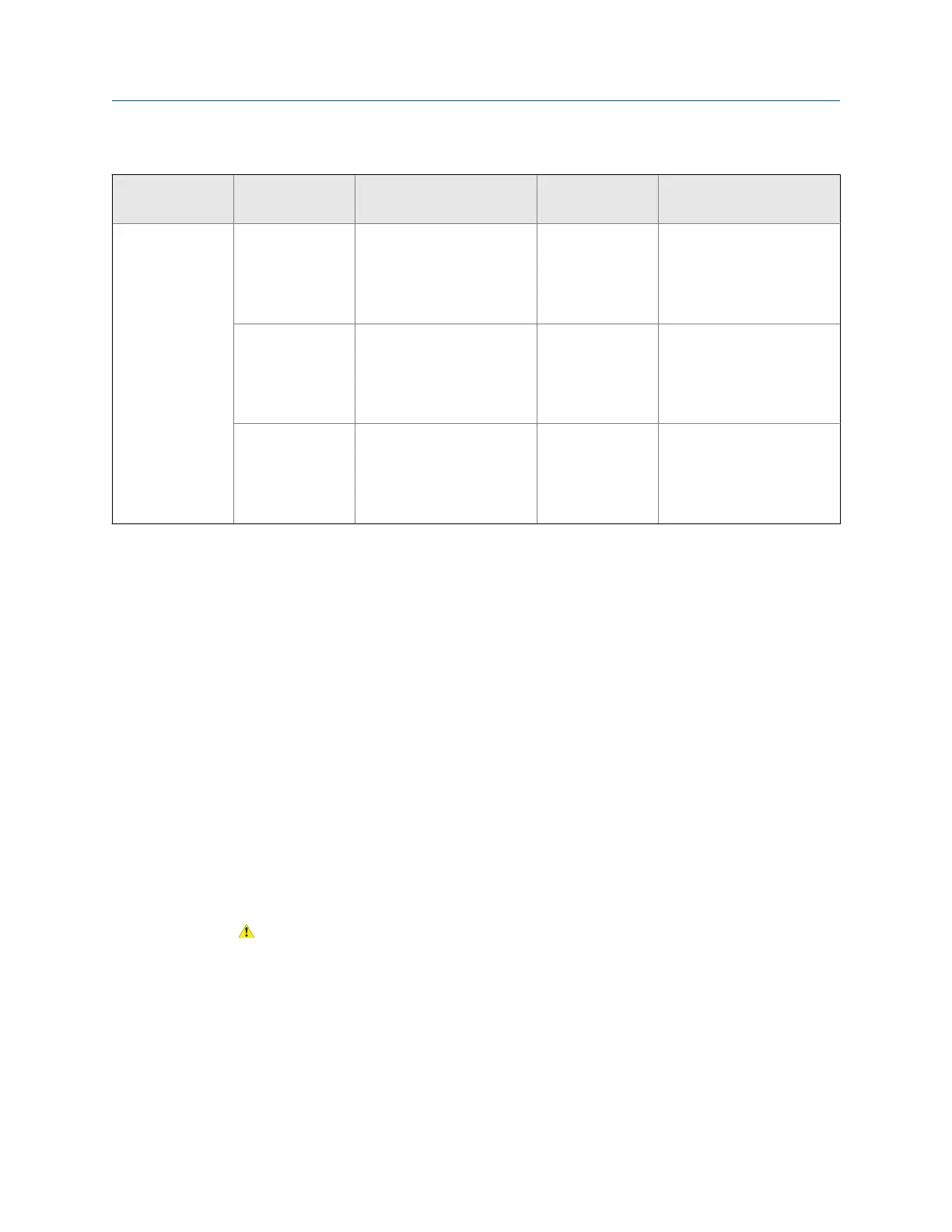

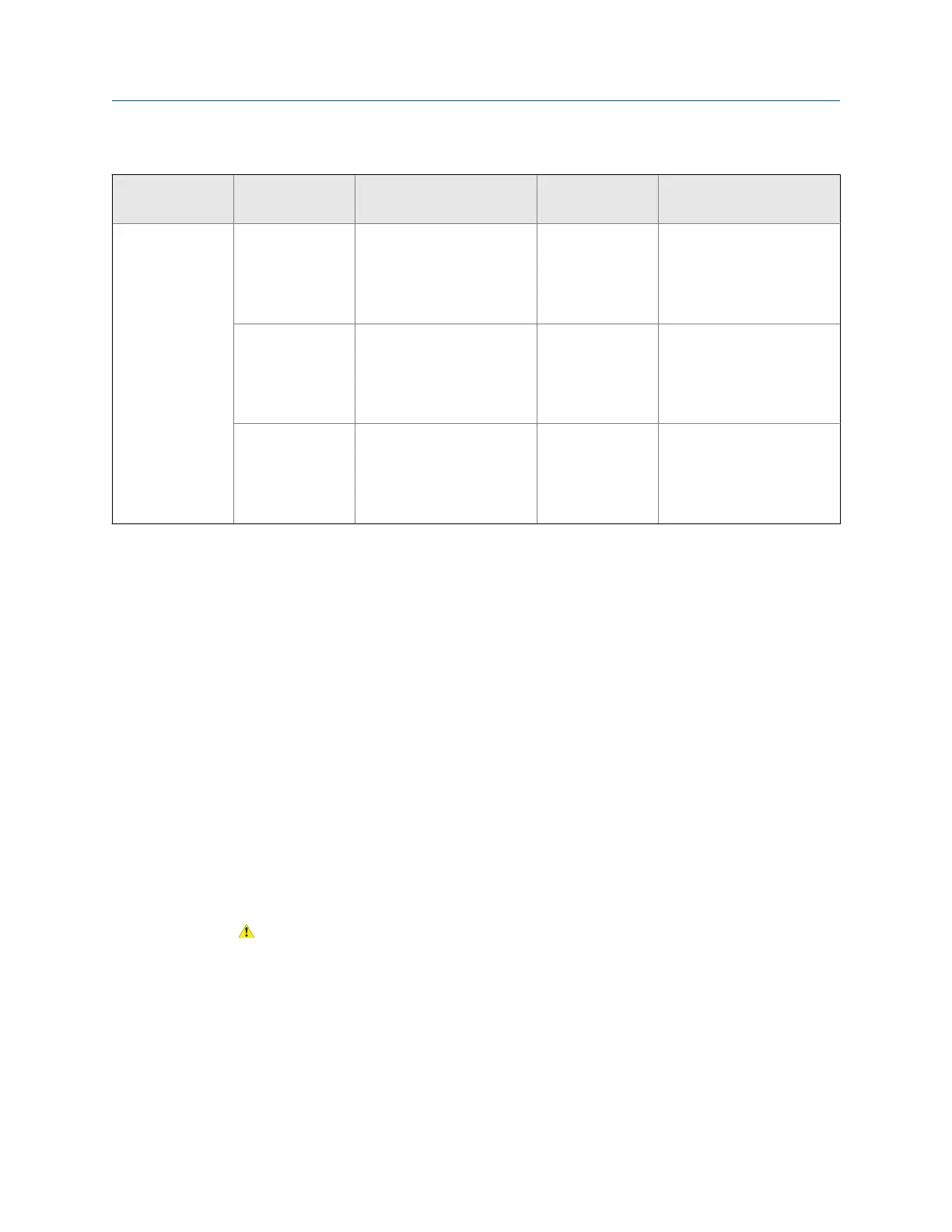

RS-485 connection parameters (continued)Table C-1:

Connection type Parameter Value

Optional or re-

quired? Auto-detection

Baud Rate 1200 to 38400 Optional Yes. The device accepts con-

nection requests that use

any valid setting, and re-

sponds using the same set-

ting.

Parity None, Odd, Even Optional Yes. The device accepts con-

nection requests that use

any valid setting, and re-

sponds using the same set-

ting.

Stop Bits 1 or 2 Optional Yes. The device accepts con-

nection requests that use

any valid setting, and re-

sponds using the same set-

ting.

7. Click Connect.

Need help? If an error message appears:

• Switch the leads and try again.

• Verify the Modbus address of the transmitter.

• Ensure that you have specified the correct port on your PC.

• Check the wiring between the PC and the transmitter.

• For long-distance communication, or if noise from an external source interferes with the

signal, install 120-Ω ½-W terminating resistors in parallel with the output at both ends of

the communication segment.

• Ensure that there is no concurrent Modbus communication to the transmitter.

C.2.3 Connect with ProLink III over HART/Bell 202

You can connect directly to the primary mA terminals on the transmitter, to any point in a

local HART loop, or to any point in a HART multidrop network.

CAUTION!

If the transmitter is in a hazardous area, do not remove the transmitter end-cap while the

transmitter is powered up. Removing the end cap while the transmitter is powered up could

cause an explosion. To connect to the transmitter in a hazardous environment, use a

connection method that does not require removing the transmitter end-cap.

Using ProLink III with the transmitter

186 Micro Motion

®

Fork Density Meters (FDM)

Loading...

Loading...