7 - Fault Finding

112

Operational Problems

Fault Finding the System

When having a problem with the system, it is good practice to go through the general fault finding schematic, before

contacting your HARDI dealer.

AutoWash Cannot be Completed

If AutoWash cannot be completed, wash the sprayer by operating the FluidBox, using the instruction for sprayers with hand

operated (non-electric) valves.

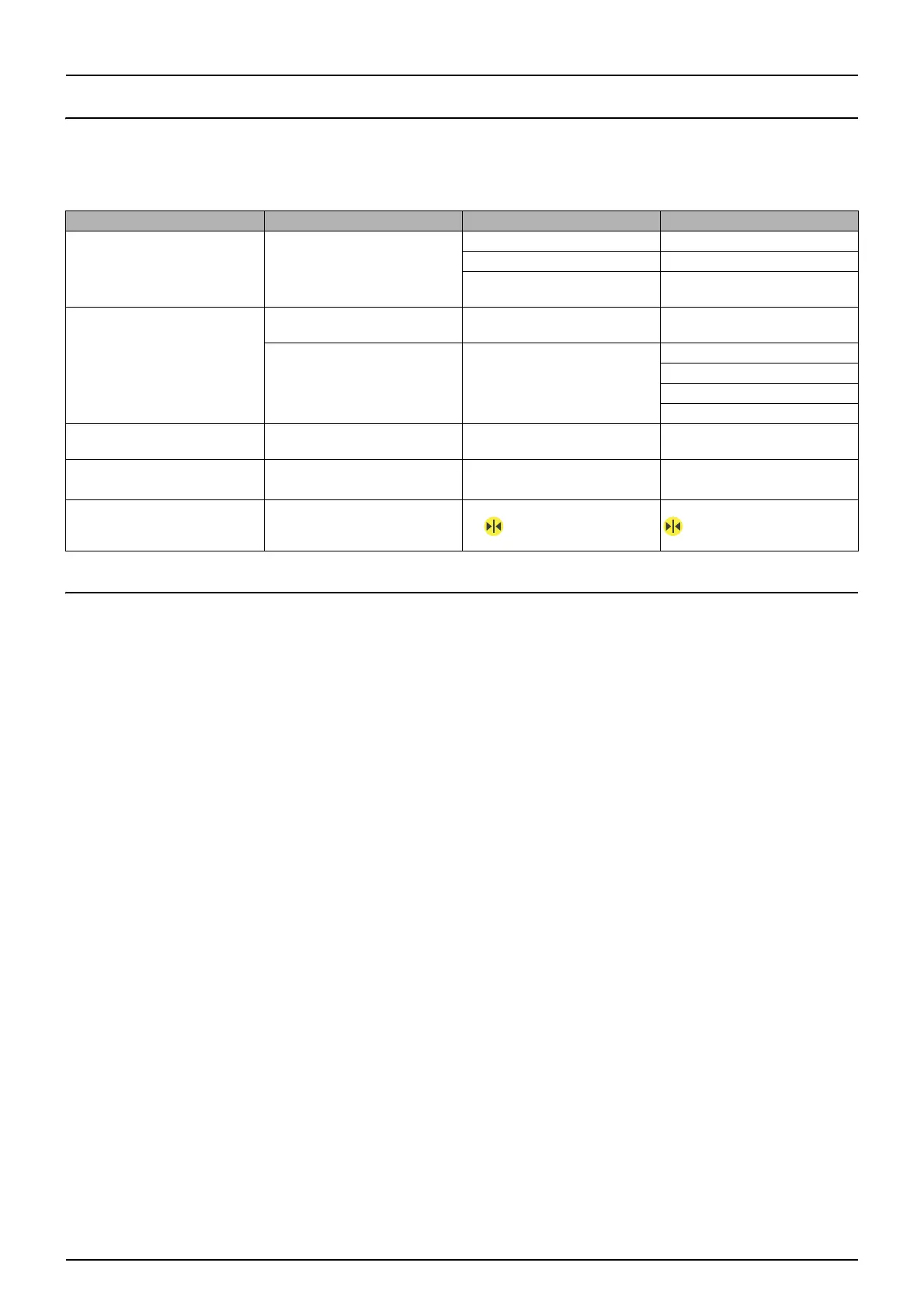

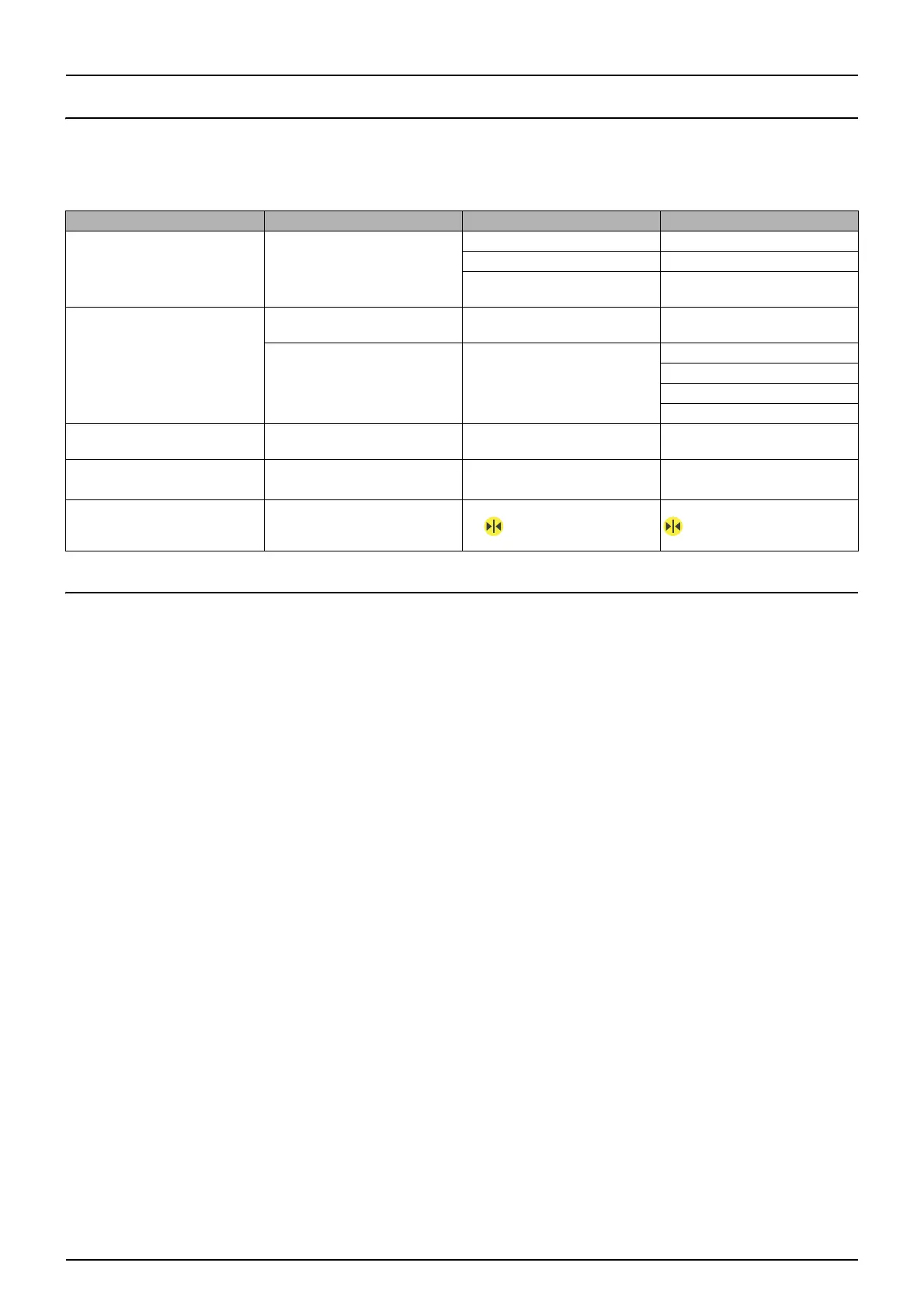

Problem Possible Cause Try/Test Check/Behavior

Flow. No or incorrect flow readout. Select l/Min in the system menu. Does this correspond to actual flow?

Is the flow PPU correct? Max. 10% change from given values.

Does pressure equalization valves leak?

(Not EFC).

Speed. No speed readout. Check LED diode on sensor. Sensor at metal = ON, Sensor at hole =

OFF.

Unstable speed readout. Max. deviation ±0,15 km/h. Distance to wheel speed ring 2-4 mm?

Are speed ring buckled?

Does sensor sense middle of holes?

Does speed ring vibrate when running?

Active boom width Incorrect boom width entered. Select boom width menu. Does menu 3.3.1 correspond to actual

boom width?

DynamicFluid4 pressure regulation

valve.

Does manual control work?

Turn valve to end stop.

Can the valve turn reverse, both at Min.

and Max.?

Track will not enter Auto mode. Steering angle is too large, when in

manual mode.

Straighten the track (more) by pressing

the button before attempt to go in

Auto again.

Does the track align when pressing the

button?

Loading...

Loading...