Maintenance

5-24 HPR800XD Auto Gas – 806500

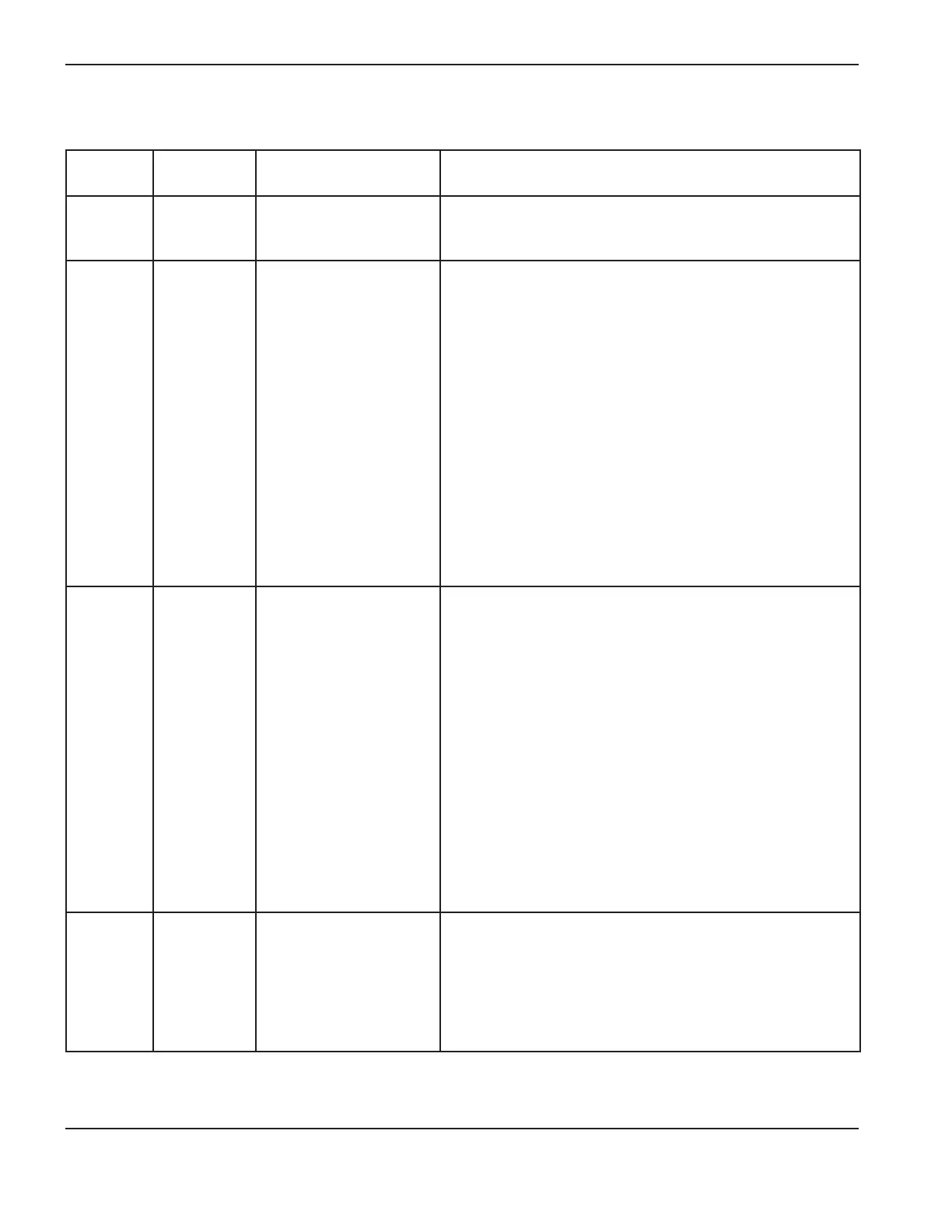

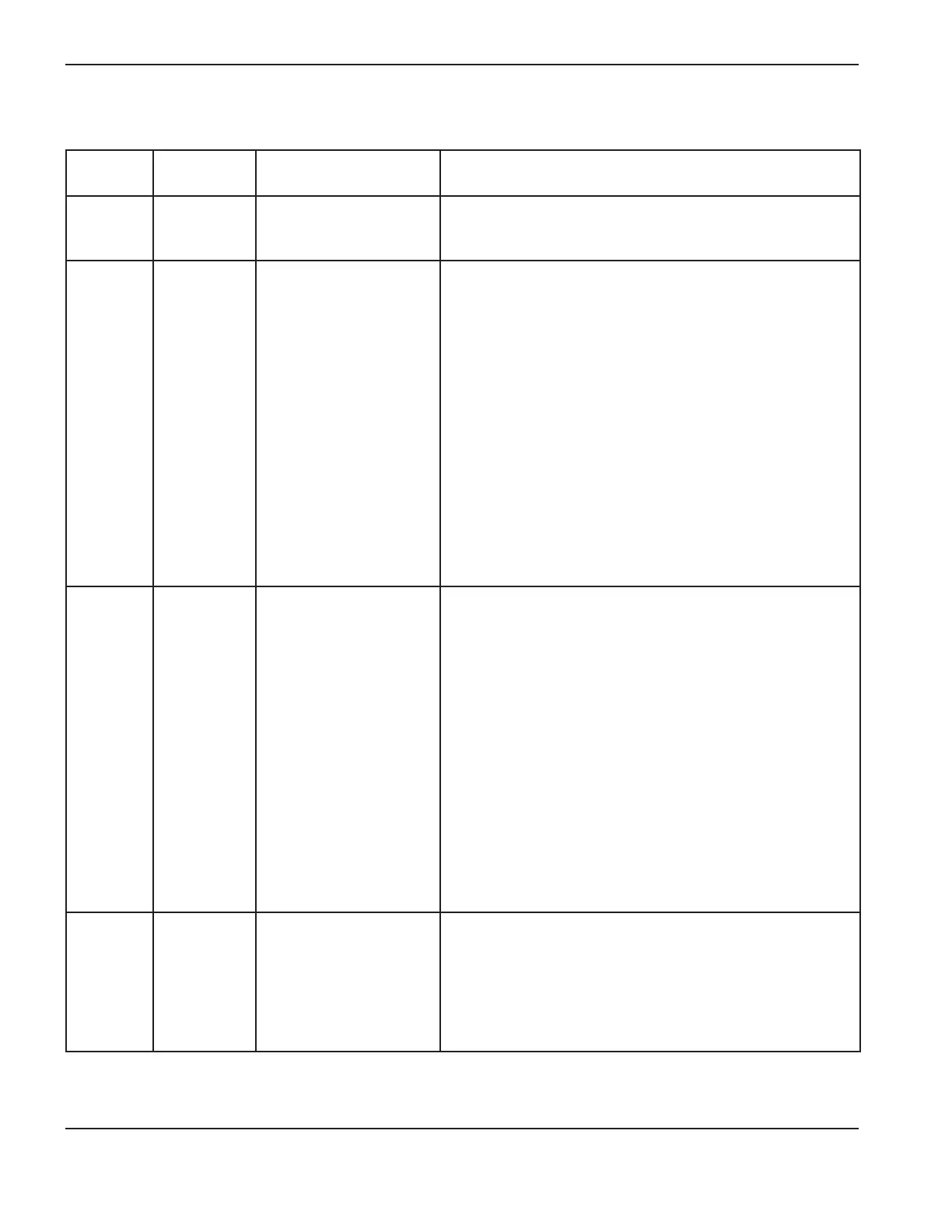

Error code troubleshooting – error codes 153 to 156, 354 to 356

Error code

number

Name Description Corrective action

153

PS EEPROM

error

EEPROM memory on

power supply control

board not working.

Replace the control board.

154

Primary

354

Secondary

Chopper 3

overcurrent

HPR400XD

Only

Chopper 3 current

feedback has exceeded

160 amps.

1. Verify that the wiring between CS3 and PCB3 is correct

and not damaged.

2. Measure voltage across current sensor.

a) Red to black = +15 VDC, Green to black = -15 VDC,

white to black = 0 VDC at idle and varies with current

output (4 VDC = 100 amps).

b) If possible, take a voltage reading on current sensor

while trying to cut. Ratio is 4 VDC = 100 amps.

c) If the current sensor voltage is approximately 6.4 VDC or

greater at idle, replace the current sensor.

3. Remove connector JC.1 from the chopper and verify that

LED1 is extinguished.

a) If LED1 is extinguished with the connector removed,

then reconnect JC.1 and try to fire the torch. If the

chopper still goes into overcurrent, replace the chopper.

b) If the chopper does not go into overcurrent, replace

PCB3..

155

Primary

355

Secondary

Chopper 4

overcurrent

HPR400XD

Only

Chopper 4 current

feedback has exceeded

160 amps.

1. Verify that the wiring between CS4 and PCB3 is correct

and not damaged.

2. Measure voltage across current sensor.

a) Red to black = +15 VDC, Green to black = -15 VDC,

white to black = 0 VDC at idle and varies with current

output (4 VDC = 100 amps).

b) If possible, take a voltage reading on current sensor

while trying to cut. Ratio is 4 VDC = 100 amps.

c) If the current sensor voltage is approximately 6.4 VDC or

greater at idle, replace the current sensor.

3. Remove connector JD.1 from the chopper and verify that

LED1 is extinguished.

a) If LED1 is extinguished with the connector removed,

then reconnect JD.1 and try to fire the torch. If the

chopper still goes into overcurrent, replace the chopper.

b) If the chopper does not go into overcurrent, replace

PCB3.

156

Primary

356

Secondary

Chopper 2

current at

power-up

HPR260XD

HPR400XD

Only

Chopper 2 current signal

is active at power-up.

See wiring diagrams in section 7

1. Verify that the voltage at CS2 is correct.

2. Verify that the wiring between CS2 and PCB3 is correct

and not damaged.

3. Swap CS2 with CS3. If the error code changes to 157,

replace the original CS2.

Loading...

Loading...