Troubleshoot Common Problems

130 810470 Operator Manual Powermax65/85/105 SYNC

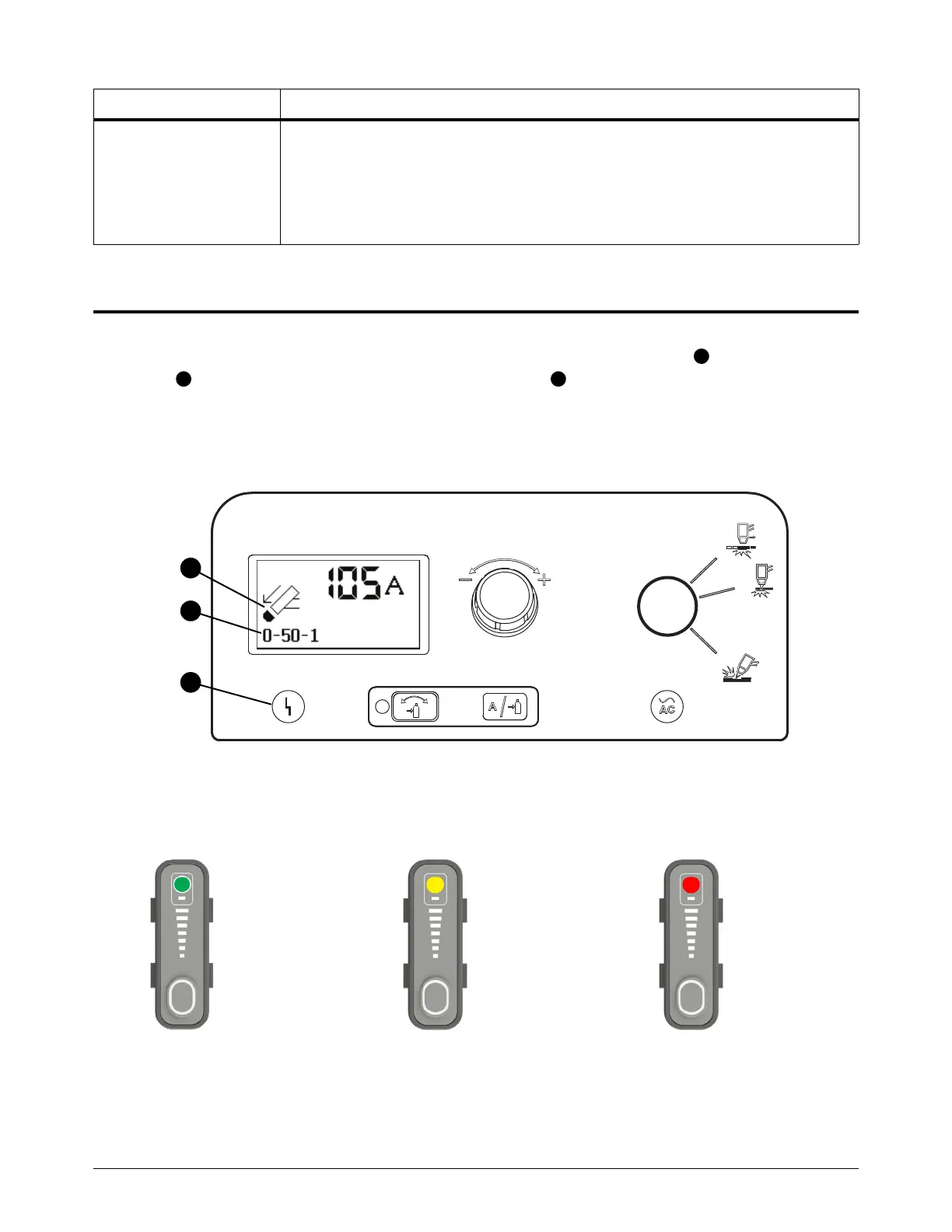

Fault codes

When a fault occurs with the plasma power supply or the torch, a fault code and related fault

icon show on the status screen. The yellow fault LED also comes on.

Fault codes are in the format N-nn-n. The fault code value identifies the importance of the fault: the

higher the number, the higher the importance. If more than one fault occurs at the same time, the

fault code with the highest importance shows.

The Power Supply Log screen shows the 10 most recent faults. Refer to page 146.

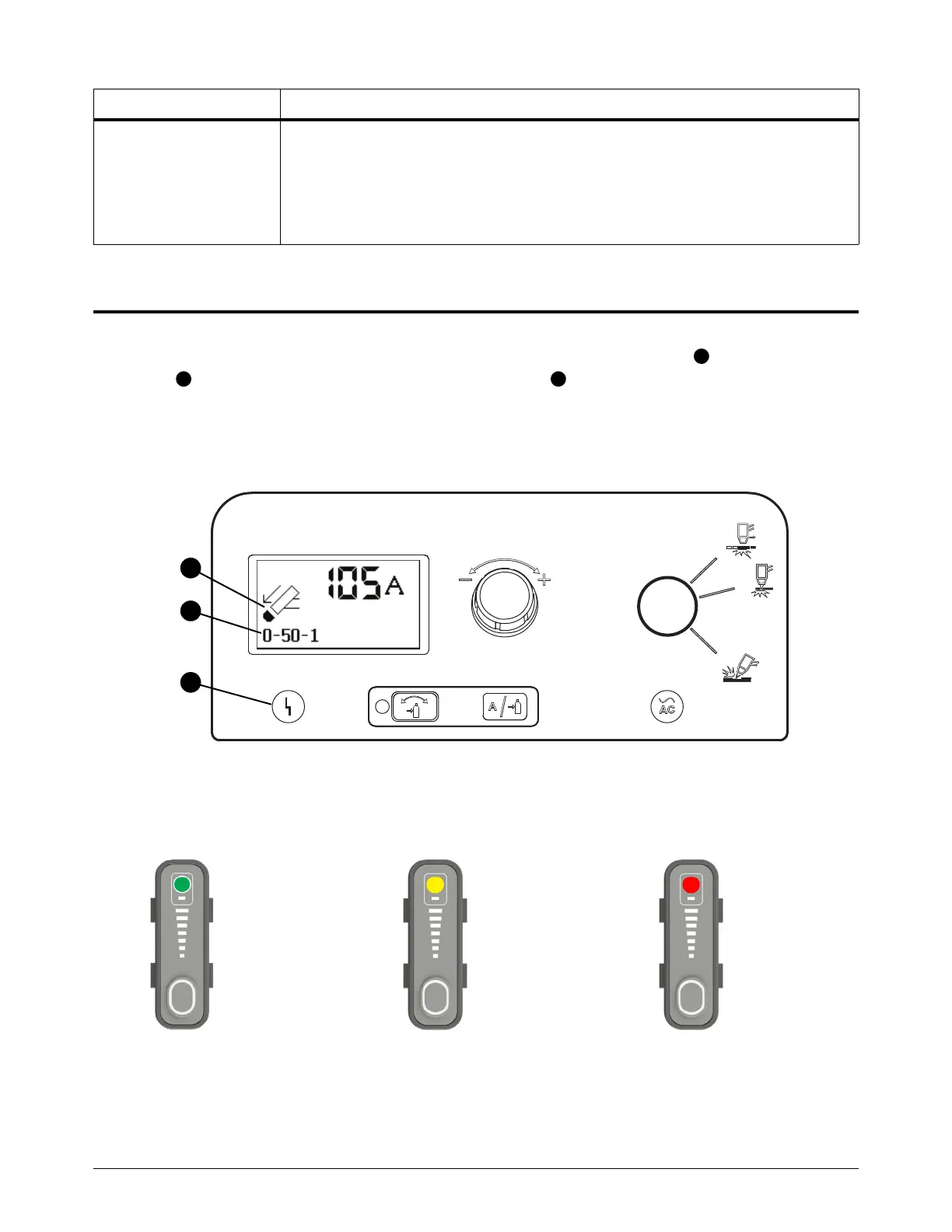

The status LED on the SmartSYNC hand torch also shows the fault status.

The gouge does not have

enough width.

• Tilt the torch down so that it is closer to the workpiece.

• Increase the arc stretch (standoff).

• Decrease the gouging speed.

• Increase output current (A).

Refer to Change the gouge contour on page 114.

Problem Solution

Green = prepared

to cut

Yello w = a 0-nn-n

fault code, or the

torch is locked

Red = a 0-32-0,

1-nn-n, 2-nn-n, or

3-nn-n fault code

Loading...

Loading...