Install and Set Up the Plasma Power Supply

Powermax65/85/105 SYNC Operator Manual 810470 29

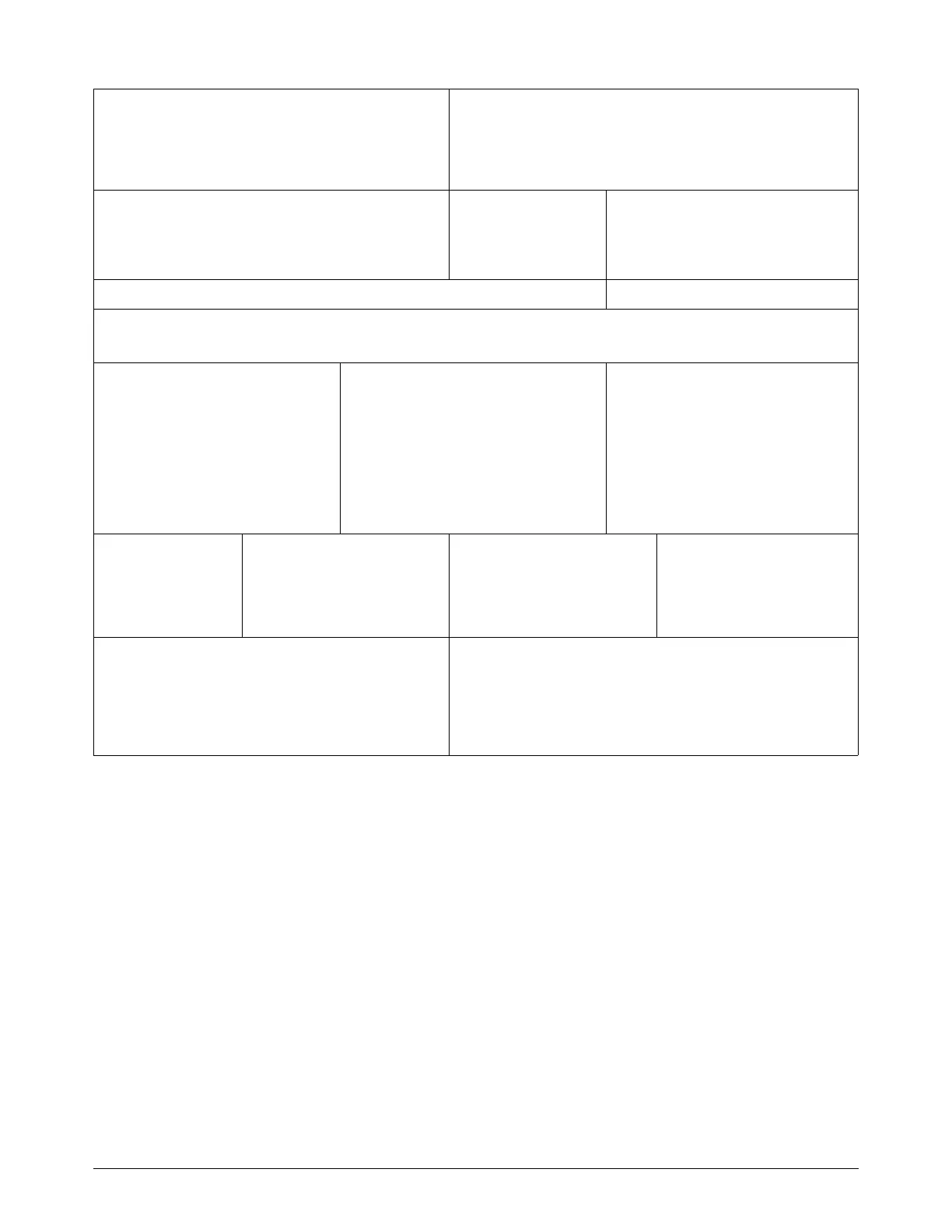

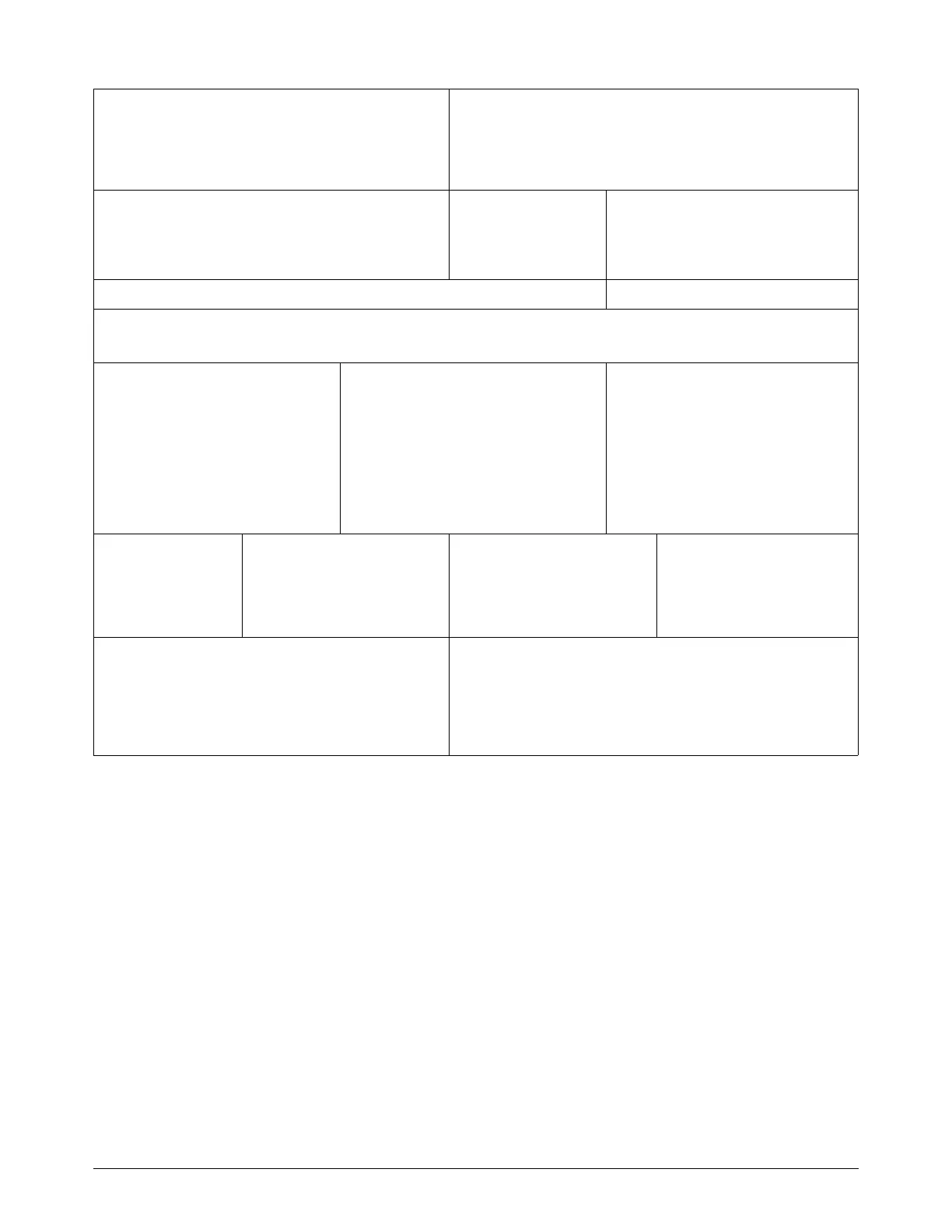

Power source efficiency at rated maximum

output power (CE systems)

230 V – 400 V CE

400 V CE

91.0%

91.9%

R

sce

– Short Circuit Ratio (CE/CCC systems only)

U

1

– Volts AC rms, 3-phase 230 V – 400 V 400 V

R

sce

235.4 176.9

EMC emissions classification CISPR 11 (CE/CCC systems only)*** Class A

Input voltage (U

1

) / Input current (I

1

) at rated output (U

2MAX

I

2MAX

)

(Refer to Connect to electrical power on page 40.)

CSA, 3-phase, 50 Hz/60 Hz CE

†,††

,

3-phase, 50 Hz/60 Hz CE

††, †††

/CCC, 3-phase,

50 Hz/60 Hz

200 V:

208 V:

240 V:

480 V:

600 V:

58 A

56 A

49 A

25 A

22 A

230 V:

400 V:

50 A

29 A

380 V:

400 V:

30 A

28 A

Gas type Air Nitrogen F5‡

Gas quality Clean, dry, oil-free per

ISO8573-1 Class 1.4.2

Refer to page 55.

99.95% pure 99.98% pure

(F5 = 95% nitrogen [N

2

],

5% hydrogen [H

2

])

Recommended gas inlet flow rates

Cutting 260 slpm (550 scfh, 9.1 scfm) at a minimum 6.2 bar (90 psi)

Maximum Removal gouging 260 slpm (550 scfh, 9.1 scfm) at a minimum 4.8 bar (70 psi)

Maximum Control gouging 260 slpm (550 scfh, 9.1 scfm) at a minimum 4.8 bar (70 psi)

* Defined as a plot of output voltage versus output current.

** Refer to the data plate on the rear of the plasma power supply for more information on duty cycle and for

IEC ratings.

*** WARNING: This Class A equipment is not intended for use in residential locations where the public low voltage

supply system supplies the electrical power. There can be difficulties in delivering electromagnetic compatibility in

those locations, because of conducted as well as radiated disturbances.

†

Equipment complies with IEC 61000-3-12 if the short-circuit power S

sc

is greater than or equal to 4,730 KVA at

the interface point between the operator’s supply and the public system. It is the responsibility of the installer or

operator of the equipment to make sure, by consultation with the distribution network operator if necessary, that the

equipment is connected only to a supply with a short-circuit power S

sc

greater than or equal to 4,730 KVA.

††

This product complies with the technical requirements of IEC 61000-3-3 and is not subject to conditional

connection.

†††

Equipment complies with IEC 61000-3-12 if the short-circuit power S

sc

is greater than or equal to 2,114 KVA at

the interface point between the operator’s supply and the public system. It is the responsibility of the installer or

operator of the equipment to make sure, by consultation with the distribution network operator if necessary, that the

equipment is connected only to a supply with a short-circuit power S

sc

greater than or equal to 2,114 KVA.

‡ F5 recommended only for cutting stainless steel. Refer to Cut stainless steel with F5 in the

Powermax65/85/105 SYNC Mechanized Cutting Guide (810480).

Loading...

Loading...