6. Description of Parameters

- 103 -

FC-50 sets running time unit in simple PLC mode. FC-51 selects the setting channel of

reference 0.

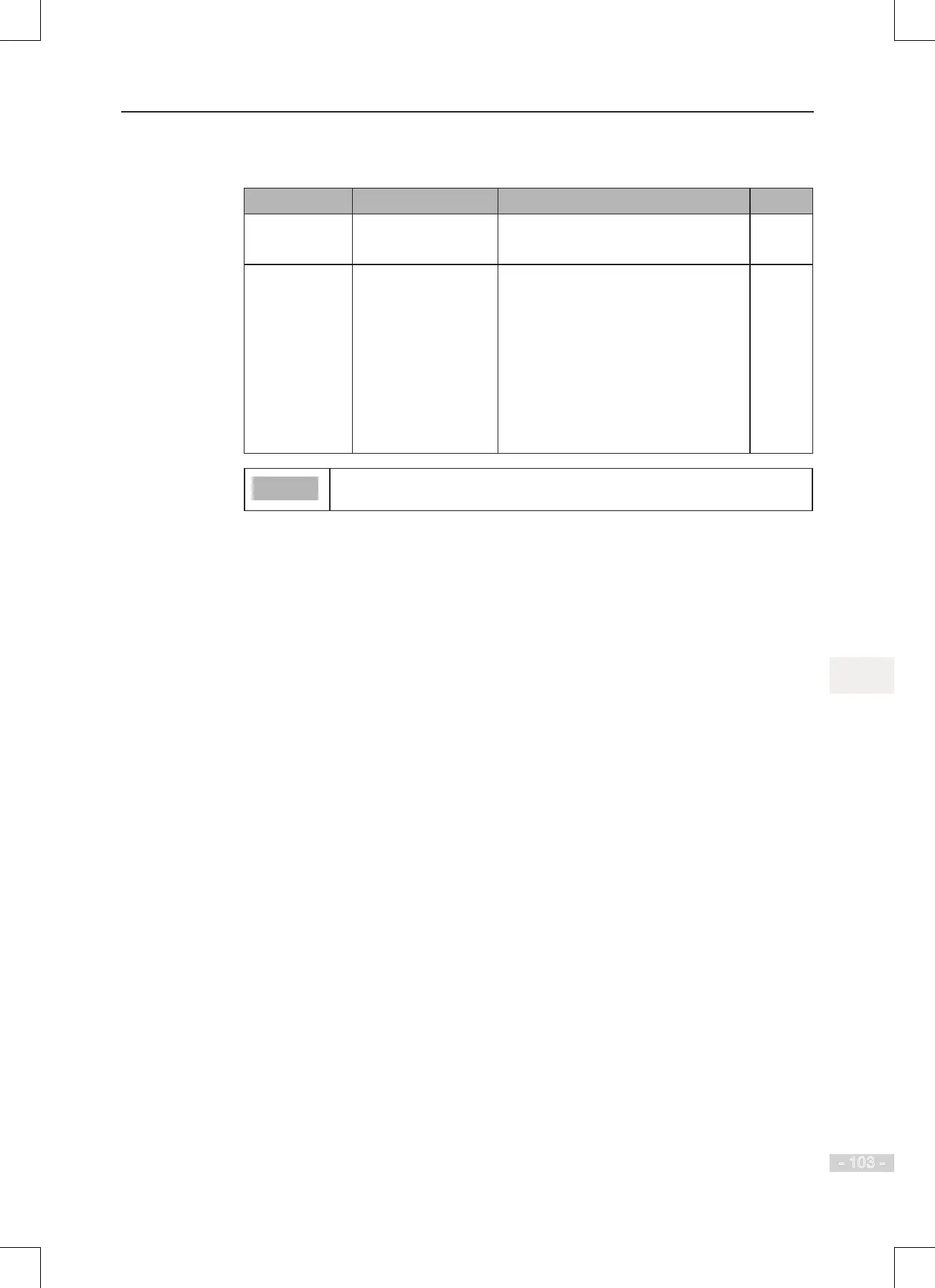

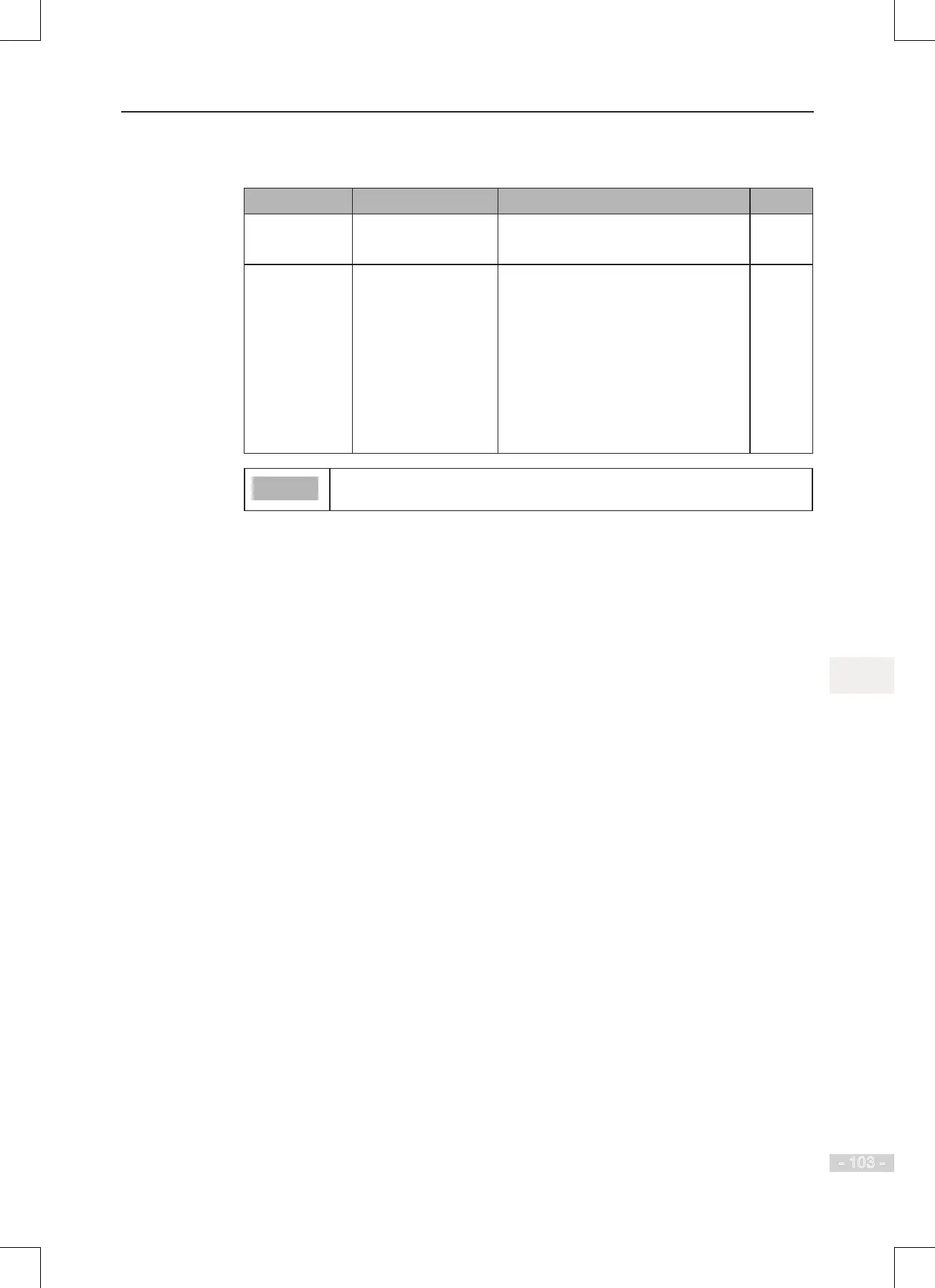

Function Code Parameter Name Setting Range Default

FC-50

Time unit of simple

PLC running

0: s (second)

1: h (hour)

0

FC-51

Reference 0 source 0: Set by FC-00

1: AI1

2: AI2

3: AI3

4: Pulse reference

5: PID

6: Set by preset frequency (F0-08),

modied via terminal UP/DOWN

0

Simple PLC can be either frequency reference setting channel or voltage

reference setting channel for V/F separation.

■

PID Reference

The PID (Proportional + Integral + Derivative) function uses system feedback for closed-

loop control of variables such as ow, pressure, temperature, and so on.

The purpose of PID control is to keep the drive output as close as possible to a desired

reference via PID adjustment.

● Proportional gain (Kp1)

A large value tends to reduce present error, but too large setting will cause system

oscillation.

● Integral time (Ti1)

The shorter the integral time is, the faster the error will be predicted. But too short

setting will cause overshoot or system oscillation.

● Derivative time (Td1)

The longer the derivative time is, the faster the system will respond to the error. But

too longer setting will cause vibration.

Loading...

Loading...