6. Description of Parameters

- 170 -

■

Droop Control

The droop control function aims at balancing the load level of two motors that drive

the same load. This function is required only when both master and slave are in speed

control.

A proper droop rate is gradually obtained during drive running. Therefore, do not set F8-

15 to a very large value. Otherwise, steady speed will decline obviously when load is very

large. You must set this parameter in both master and slave.

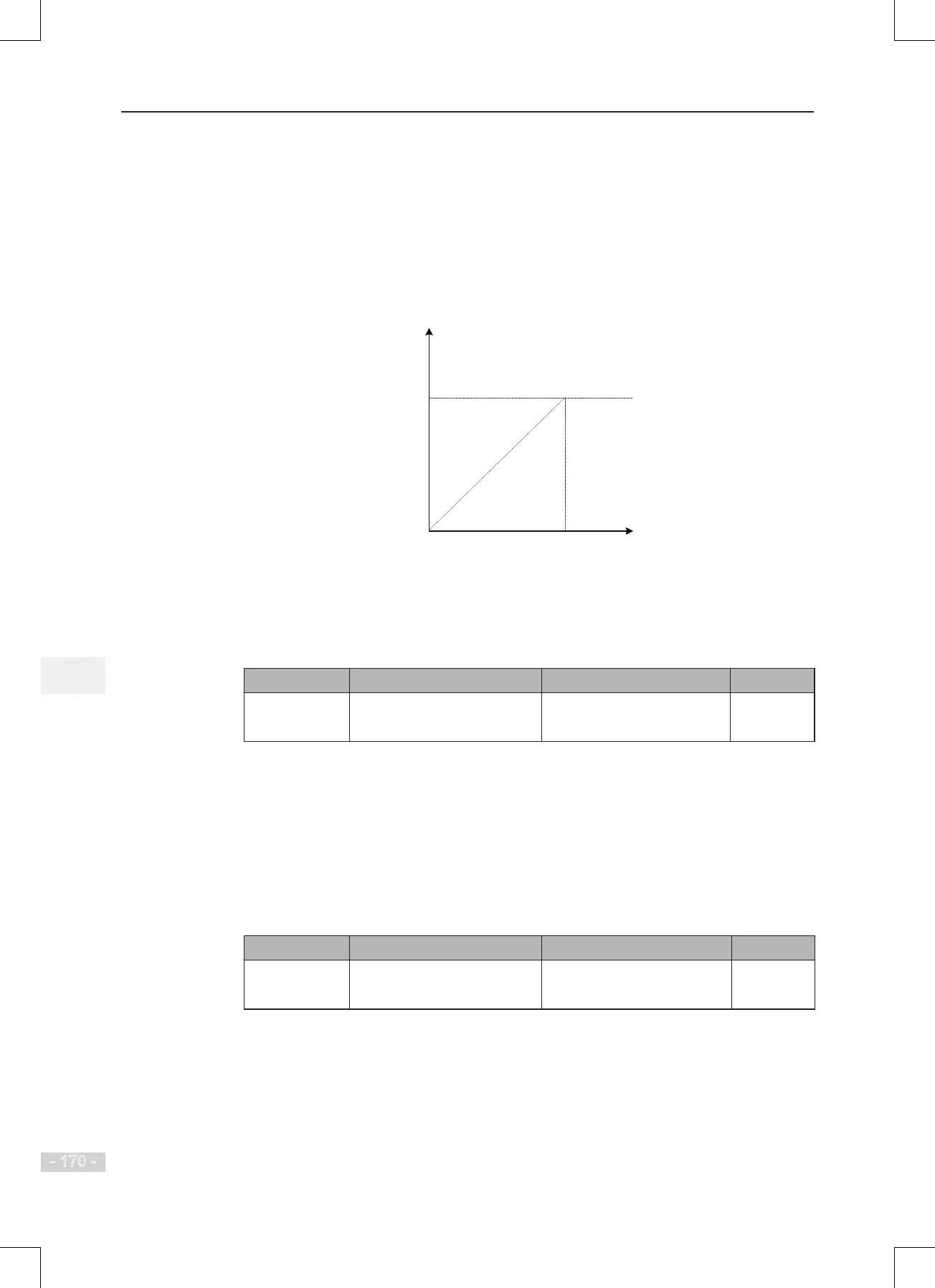

Figure 6-57 Relationship between droop rate and output torque

Droop rate

(Hz)

Output

torque (%)

0

100%

● Droop speed = rated motor frequency x output torque x droop rate

● Actual AC drive frequency = frequency reference - droop speed

Suppose that F8-15 is set to 10%, rated motor frequency is 50 Hz, and output torque is

50%. Actual drive frequency = 50 Hz – 50 x 50% x (1.00/10) = 47.5 Hz.

Function Code Parameter Name Setting Range Default

A8-00

Point-point communication 0: Disabled

1: Enabled

0

This function parameter determines whether to enable point-point communication.

The point-point communication indicates direct communication between two or more

drives via CANlink. The master sends frequency or torque reference to slaves based on

frequency or torque signal it receives.

When connecting multiple AC drives via CANlink card, install a terminal resistor to the

CANlink card of the end drive.

Once this function is enabled, CANlink communication addresses of the master and

slaves are matched automatically. The baud rate is set in Fd-00.

Function Code Parameter Name Setting Range Default

A8-01

Master or slave selection 0: Master

1: Slave

0

This function parameter determines whether the AC drive is master or slave.

Loading...

Loading...