S.G

GENERAL

92.4mm

STROKE

SERIES

WSM,0109A

kgfom

0.7 to 0.9

9.5

to 10.0

4.7

to 5.2

7.0

to 7.5

10.0to

11.0

3.7

to 4.2

4.5

to 5.0

2.4 to 2.8

2.4

to 2.8

14.0to 16.0

32.0

to

34.0

2.0

to 2.5

5.0 to 7.0

1.5

to 2.0

2.5

to 3.5

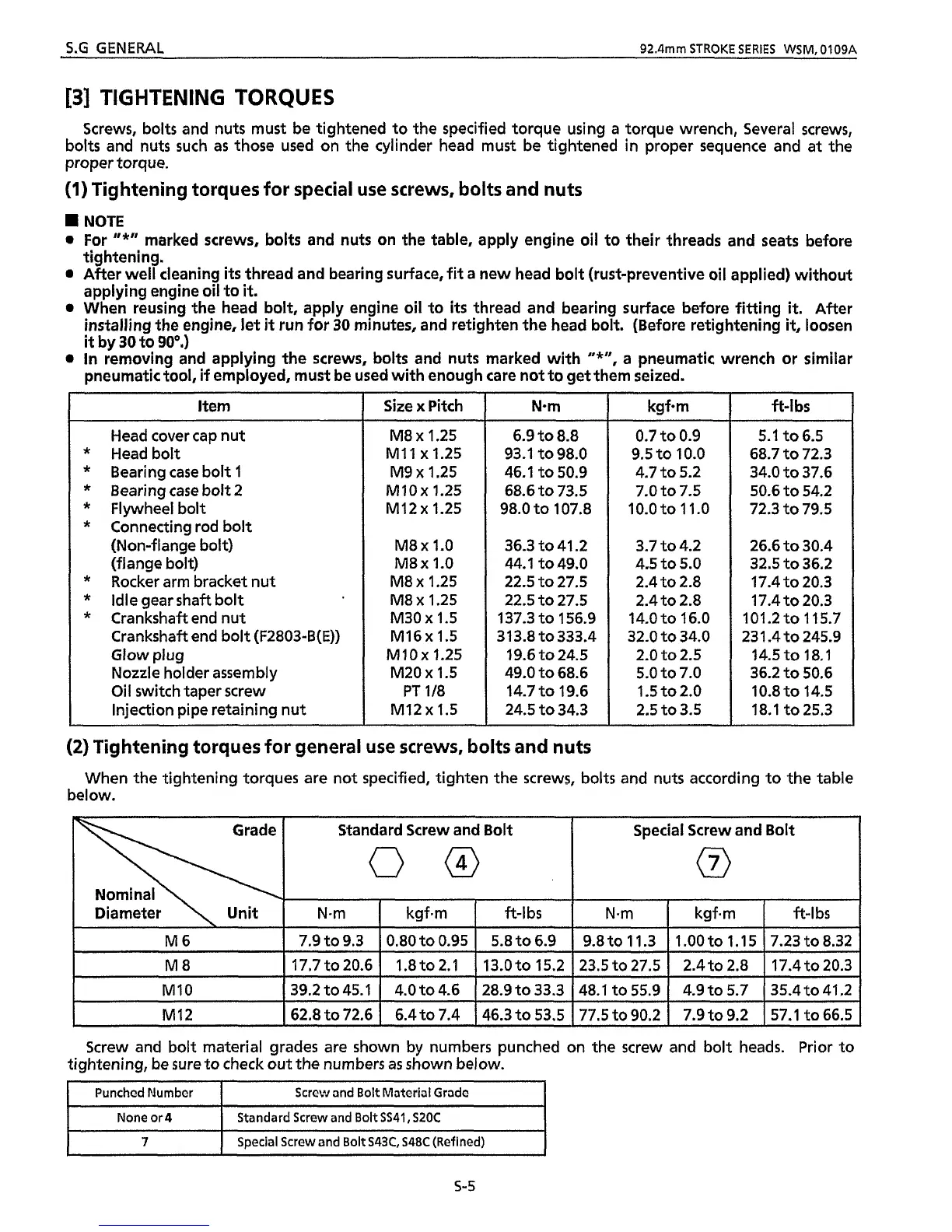

[3J

TIGHTENING TORQUES

ft-I

bs

5.1 to6.5

68.7

to 72.3

34.0

to 37.6

50.6

to 54.2

72.3 to 79.5

26.6

to 30.4

32.5

to

36.2

17.4 to 20.3

17.4

to 20.3

101.2to 115.7

231.4

to 245.9

14.5

to

18.1

36.2 to 50.6

10.8to

14.5

18.1

to 25.3

Screws, bolts and nuts must be tightened to the specified torque using

a

torque wrench, Several screws,

bolts and nuts such

as

those used on the cylinder head must be tightened in proper sequence and

at

the

proper torque.

(1)

Tightening torques for special use screws, bolts and nuts

NOTE

0

For

"*"

marked screws, bolts and nuts on the table, apply engine oil to their threads and

seats

before

tightening.

0

After

well

cleaning

its

thread and bearing surface,

fit

a

new head bolt (rust-preventive oil applied) without

applying engine oil to

it.

0

When reusing the head bolt, apply engine oil to

its

thread and bearing surface before fitting

it.

After

installing the engine,

let

it

run

for

30

minutes, and retighten

the

head bolt. (Before retightening

it,

loosen

it

by

30

to

90°.)

0

in removing and applying the screws, bolts and nuts marked with

"*",

a

pneumatic wrench or similar

pneumatic tool,

if

employed, must be used with enough care not to get them seized.

Unit

N-m

Item

Head cover cap nut

*

Headbolt

*

Bearing

case

bolt 1

*

Bearing case bolt 2

*

Flywheel bolt

*

Connecting rod bolt

(Non-flange bolt)

(flange bolt)

*

Rocker arm bracket nut

*

idle gear shaft bolt

*

Crankshaft end nut

Crankshaft end bolt

(F2803-B(E))

Glow

plug

Nozzle holder assembly

Oil switch taper screw

Injection pipe retaining nut

kgf.m

ft-l

bs

Size

x

Pitch

N-m

9.8 to

1

1.3

M8 x 1.25

M11 x 1.25

M9

x

1.25

MlOx 1.25

M12x 1.25

M8 x

1.0

M8x

1.0

M8 x 1.25

M8 x 1.25

M30

x

1.5

M16x 1.5

MlOx 1.25

M20 x 1.5

PT

118

M12 x 1.5

kgf-m

ft-I

bs

1

.OO

to 1.15 7.23 to 8.32

Nom

6.9 to

8.8

93.1 to 98.0

46.1

to 50.9

68.6

to 73.5

98.0

to 107.8

36.3

to 41.2

44.1

to 49.0

22.5

to

27.5

22.5

to 27.5

137.3

to 156.9

313.8 to333.4

19.6

to 24.5

49.0

to 68.6

14.7

to 19.6

24.5

to 34.3

M6

M8

7.9 to 9.3

0.80

to 0.95 5.8 to 6.9

17.7

to 20.6 1.8 to 2.1 13.0

to

15.2

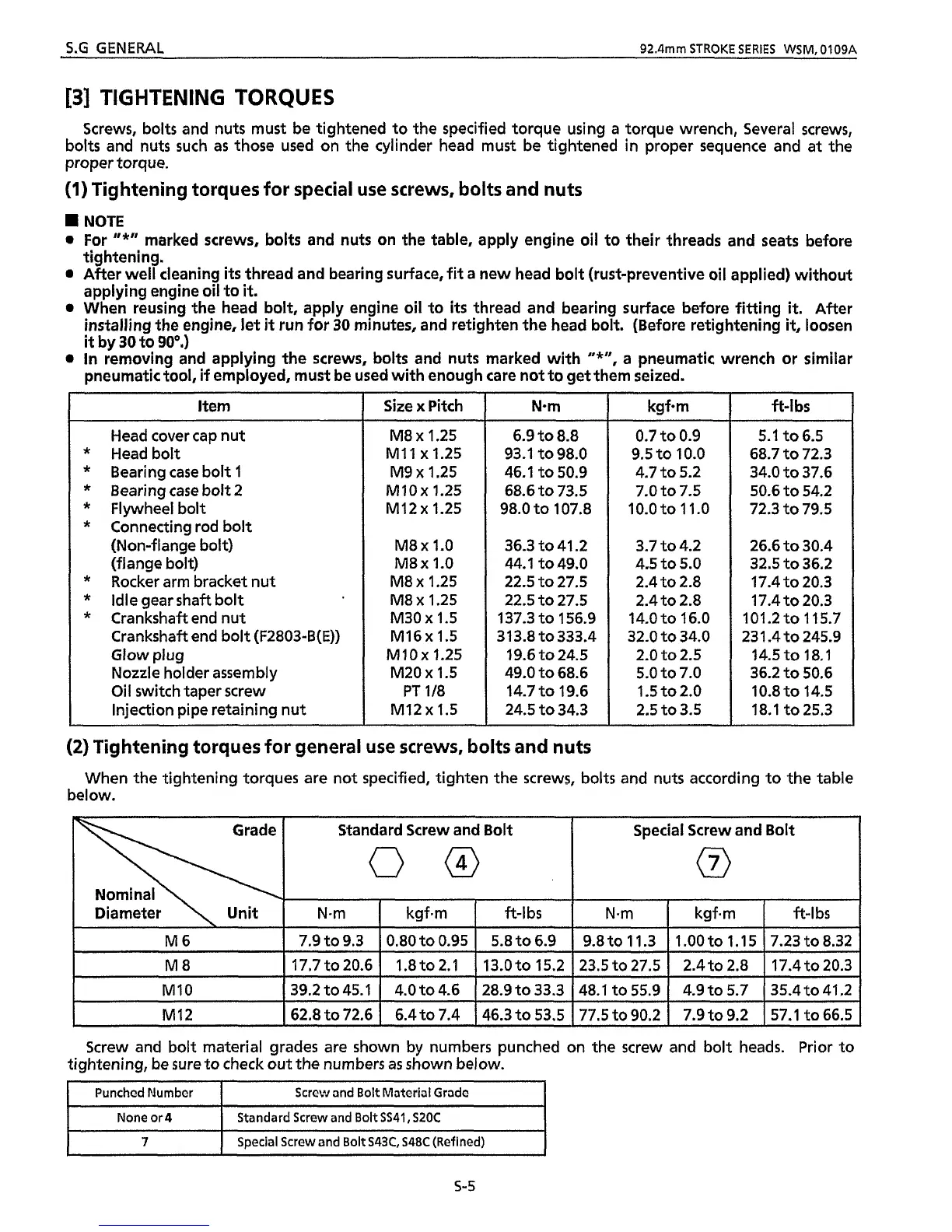

(2)

Tightening torques

for

general use screws,

bolts

and nuts

below.

When the tightening torques

are

not specified, tighten the screws, bolts and nuts according to the table

48.1

to 55.9

77.5

to 90.2

\

Grade

I

Standard Screw and Bolt

4.9

io

5.7 35;Go 41.2

7.9

to 9.2 57.1 to 66.5

I\\

I

None or4

7

00

Standard Screw and Bolt

SS41, S20C

Special Screw and Bolt

S43C, S48C

(Refined)

~

MI0

I

39.2 to 45.1

I

4.0 to 4.6

I

28.9 to 33.3

I

M12

I

62.8 to 72.6

I

6.4 to 7.4

I

46.3 to 53.5

Special Screw and Bolt

(7)

23.5 to 27.5

I

2.4 to 2.8

I

17.4 to 20.3

I

Screw and bolt material grades are shown by numbers punched on the screw and bolt heads. Prior to

tightening, be sure to check out

the

numbers

as

shown below.

Punchcd Number

1

Scrcvr and Bolt Material Gradc

I

5-5

Loading...

Loading...