5.4

FUELSYSTEM

92.4mm STROKE SERIES WSM,

01092

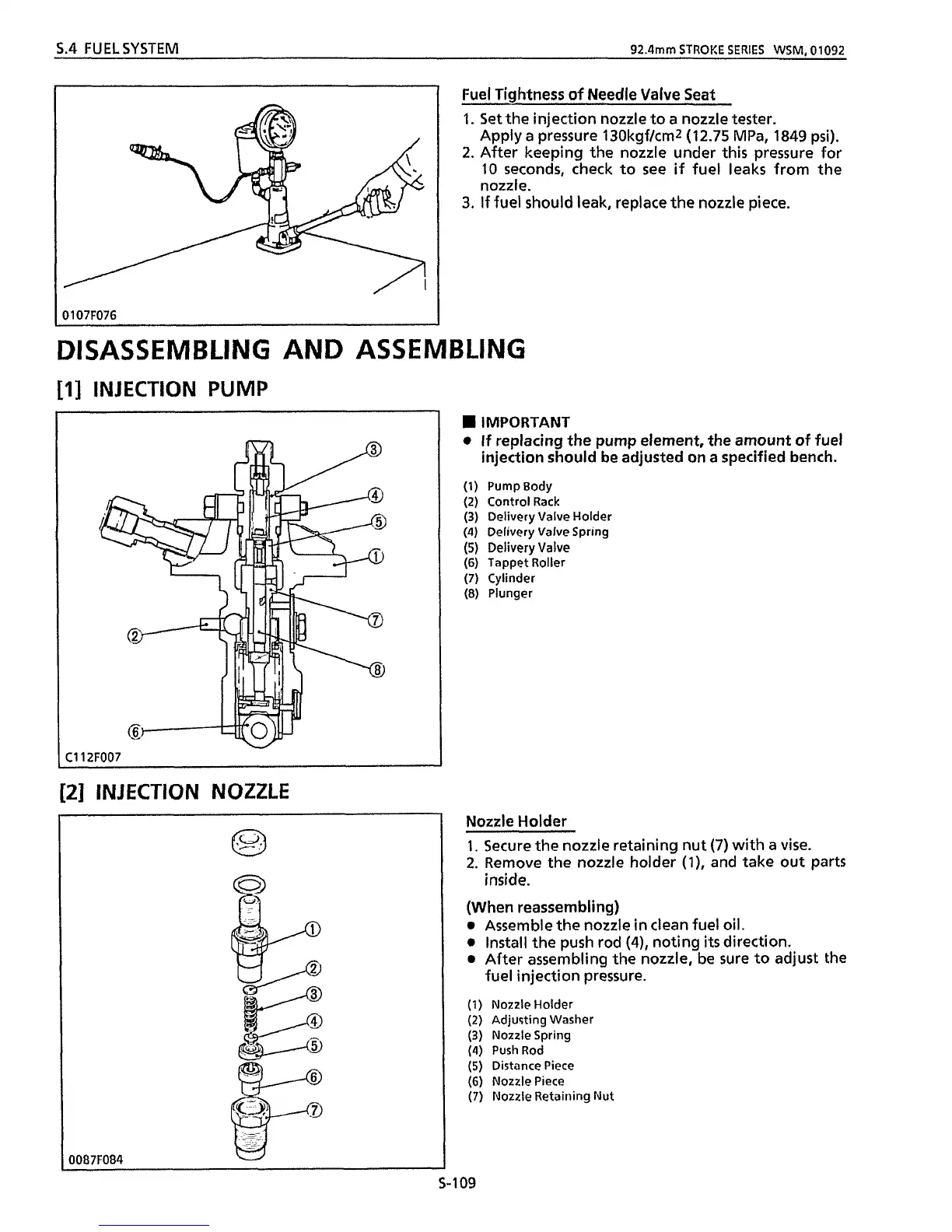

Fuel

Tightness

of

Needle Valve Seat

I.

Set

the

injection nozzle to a nozzle tester.

Apply a pressure 130kgfkm2

(12.75

MPa, 1849 psi).

2.

After keeping the nozzle under

this

pressure for

10

seconds, check

to

see

if

fuel leaks from the

nozzle.

3.

If

fuel should leak, replace the nozzle piece.

01

07F076

DI

SASSE

M

B

LI

NG

AND

ASS

EM

BUNG

[I]

INJECTION

PUMP

c1

12F007

[Z]

INJECTION

NOZZLE

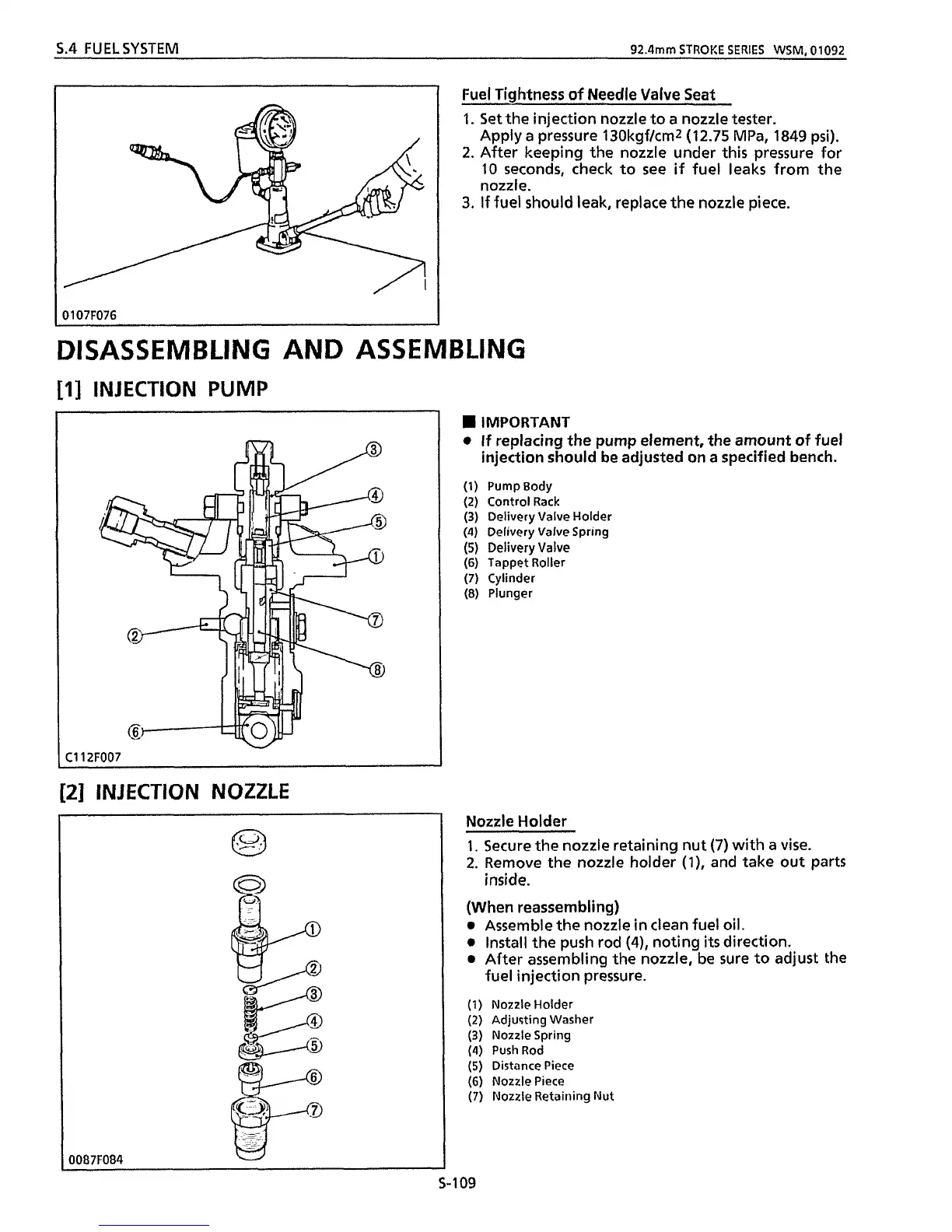

IMPORTANT

0

If

replacing the pump element, the amount

of

fuel

injection should

be

adjusted on a specified bench.

(1)

PumpBody

(2) Control Rack

(3)

Delivery Valve Holder

(4)

Delivery

Valve

Spring

(5)

Delivery

Valve

(6)

Tappet Roller

(7)

Cylinder

(8)

Plunger

Nozzle Holder

1.

Secure the nozzle retaining nut

(7)

with

a vise.

2.

Remove the nozzle holder

(l),

and take out parts

inside.

(When reassembling)

0

Assemble the nozzle

in

clean fuel oil.

0

Install the push rod (4), noting

its

direction.

0

After assembling the nozzle, be sure to adjust the

(1)

Nozzle Holder

(2)

Adjusting Washer

(3)

Nozzle Spring

(4)

PushRod

(5)

Distance Piece

(6)

Nozzle Piece

(7)

Nozzle Retaining Nut

fuel injection pressure.

s-109

Loading...

Loading...