S.G

GENERAL

92.4mm STROKE

SERIES

WSM.0109A

Varve

arrengernent

Adjustable

(7)

Check

Point

of

Every

800

hours

D1403-B(E) V1903-B(E)

D1703-B(E) V2203-B(E)

Checkina Valve Clearance

IN.

00

0

0

00

I

EX.

0

0

00

I

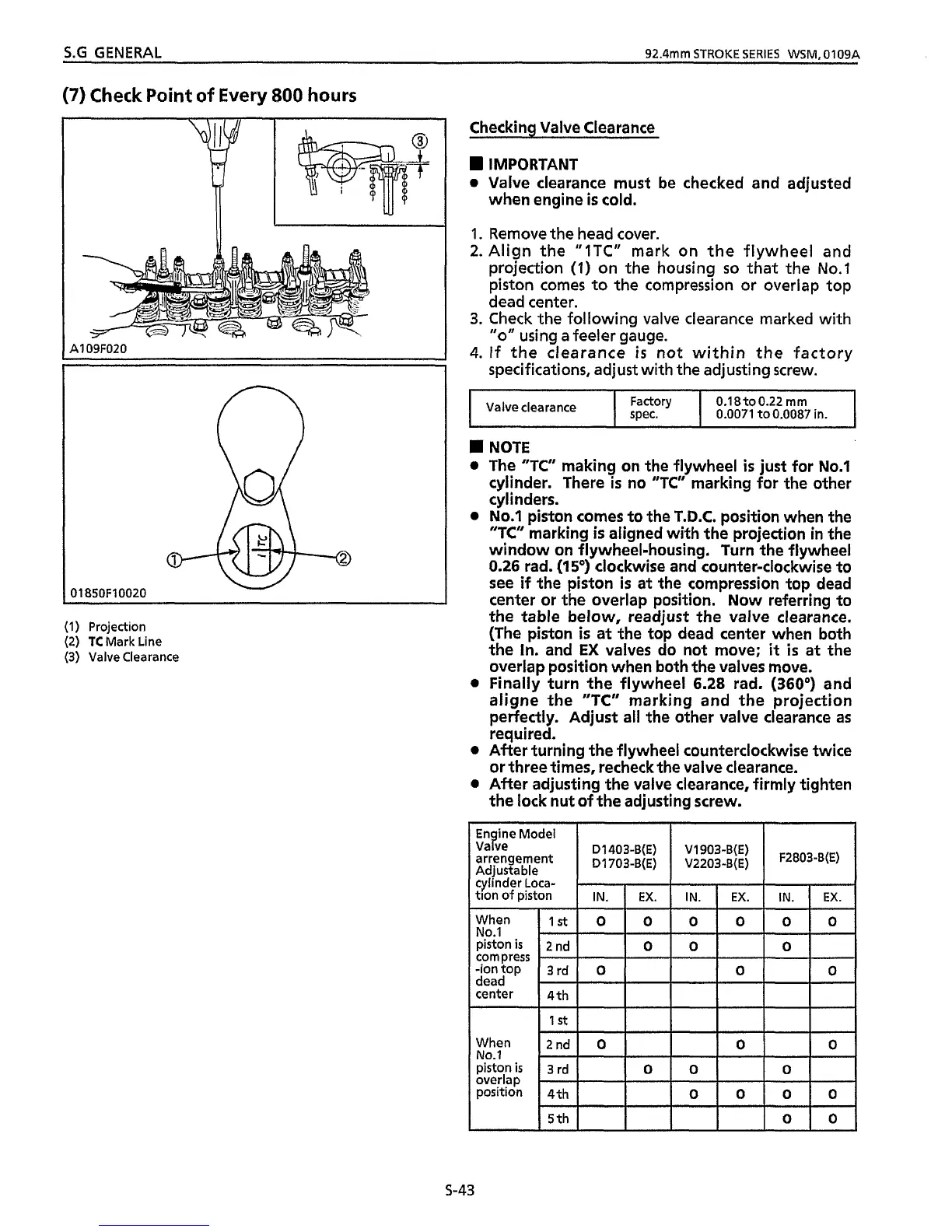

A109F020

2nd

3 rd

4th

5th

I

0

0

00

0

0

@J

01

85nF10020

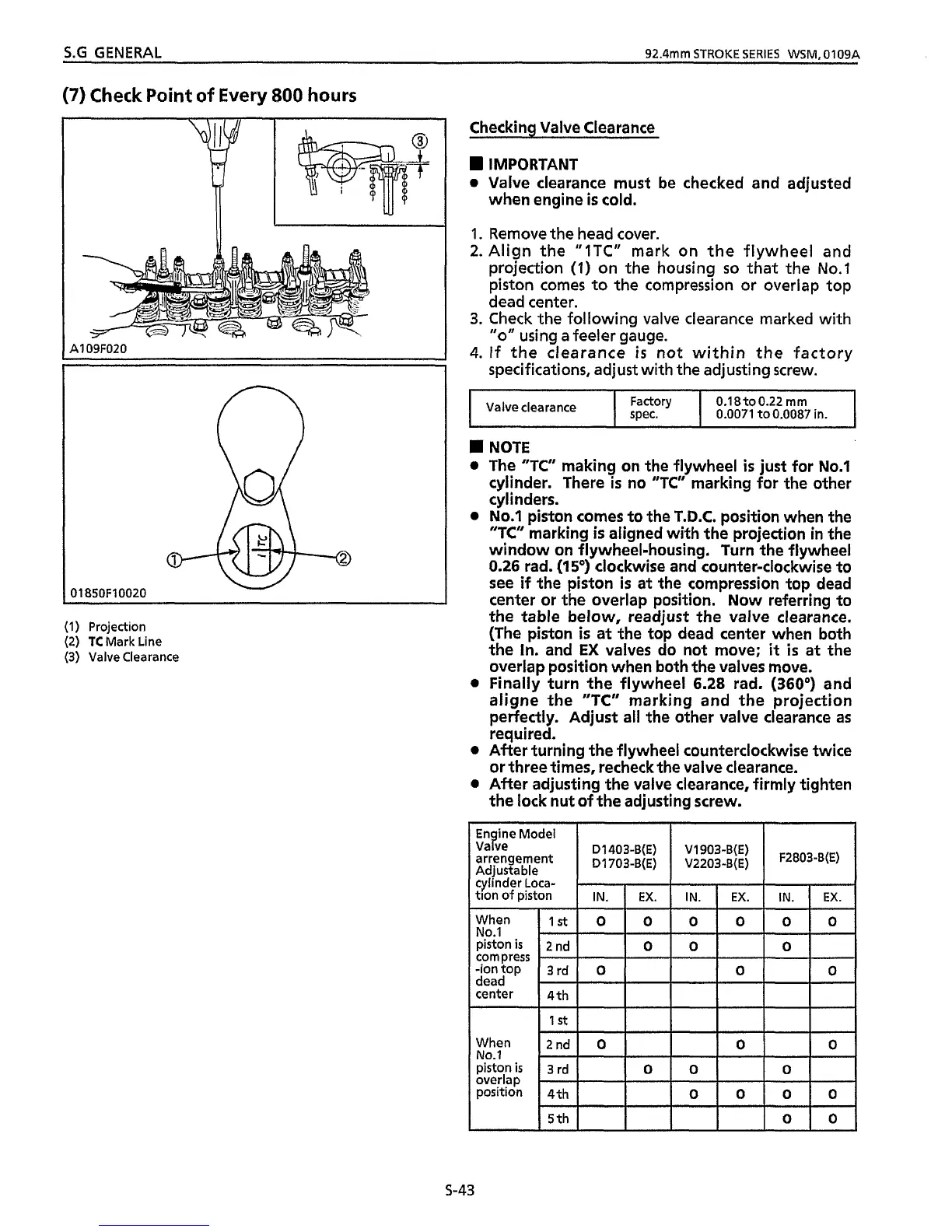

(1) Projection

(2)

TC

Mark Line

(3) Valve Clearance

IMPORTANT

0

Valve clearance must be checked and adjusted

when engine

is

cold.

1.

Remove the head cover.

2.

Align the

"ITC"

mark on the flywheel and

projection

(1)

on the housing

so

that the No.7

piston comes to the compression or overlap top

dead center.

3.

Check the following

valve

clearance marked with

"off

using

a

feeler gauge.

4.

If

the clearance

is

not within the factory

specifications, adjust with the adjusting screw.

I

I

bgry

I

0.18to0.22rnrn

0.0071

to

0.0087 in.

I

Valve clearance

~

NOTE

0

The

"TC"

making on the flywheel

is

just for No.1

cylinder. There

is

no

"TC"

marking for the other

cylinders.

0

No.1 piston comes to the T.D.C. position when the

"TC" marking

is

aligned with the projection in the

window on flywheel-housing. Turn the flywheel

0.26

rad.

(1

5")

clockwise and counter-clockwise to

see

if

the piston

is

at the compression top dead

center or the overlap position. Now referring to

the table below, readjust

the

valve clearance.

(The piston

is

at the top dead center when both

the In. and

EX

valves do not move;

it

is

at

the

overlap position when both the valves move.

0

Finally turn

the

flywheel

6.28

rad.

(360")

and

aligne

the "TC" marking and

the

projection

perfectly. Adjust

all

the other valve clearance

as

required.

0

After turning

the

flywheel counterclockwise twice

or three times, recheck the valve clearance.

0

After adjusting the valve clearance, firmly tighten

the lock nut of the adjusting screw.

Enaine Model

I

I

cylinder Loca-

tion

of

piston

corn

press

-ion top

dead

center

When

No.

1

piston

is

overlap

position

-

EX.

0

-

0

s-43

Loading...

Loading...