7. CYLINDER/PISTON

7-2

DINK 200i/125

SERVICE INFORMATION

GENERAL INSTRUCTIONS

The cylinder and piston can be serviced with the engine installed in the frame.

When installing the cylinder, use a new cylinder gasket and make sure that the dowel pins are

correctly installed.

After disassembly, clean the removed parts and dry them with compressed air before inspection.

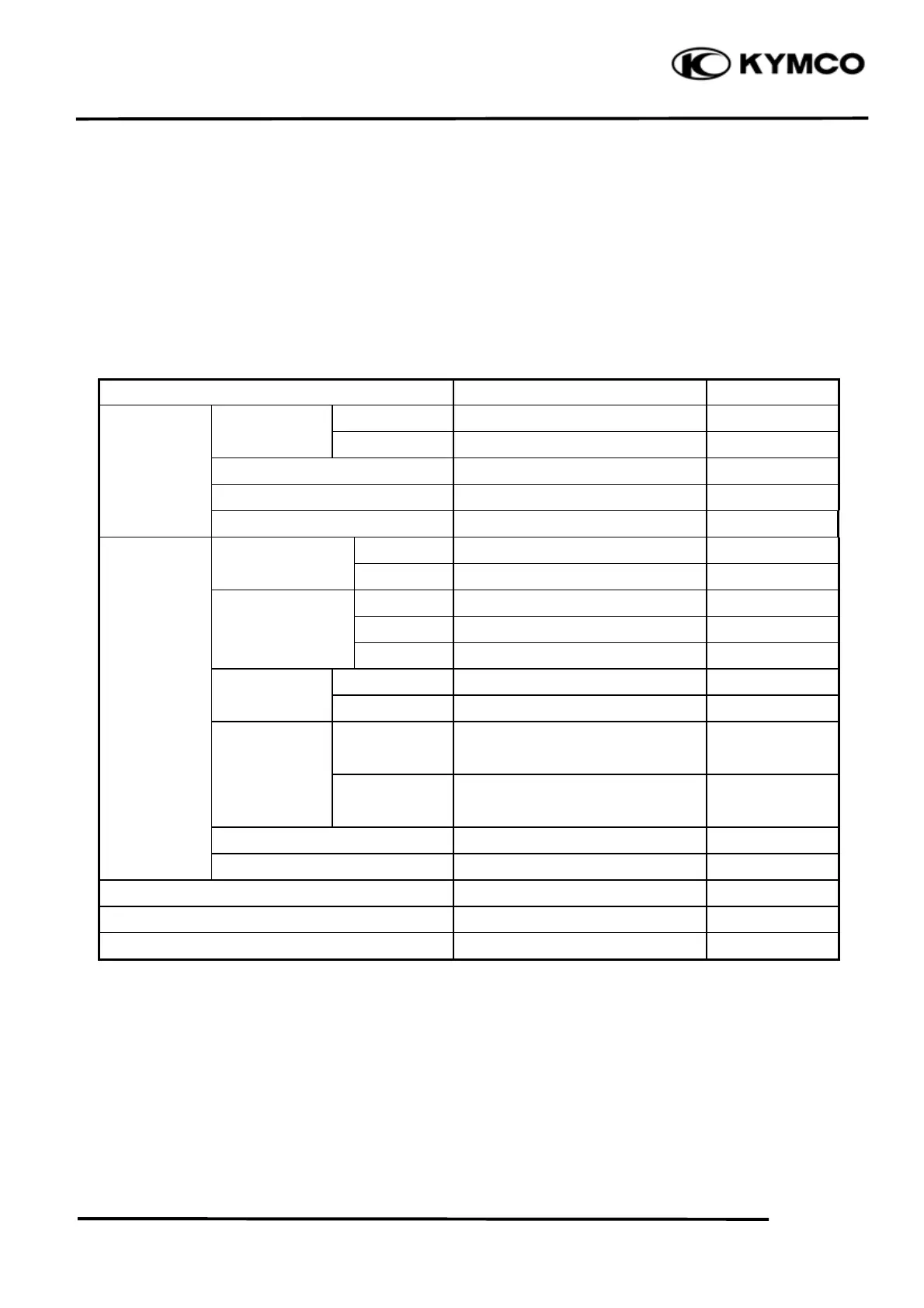

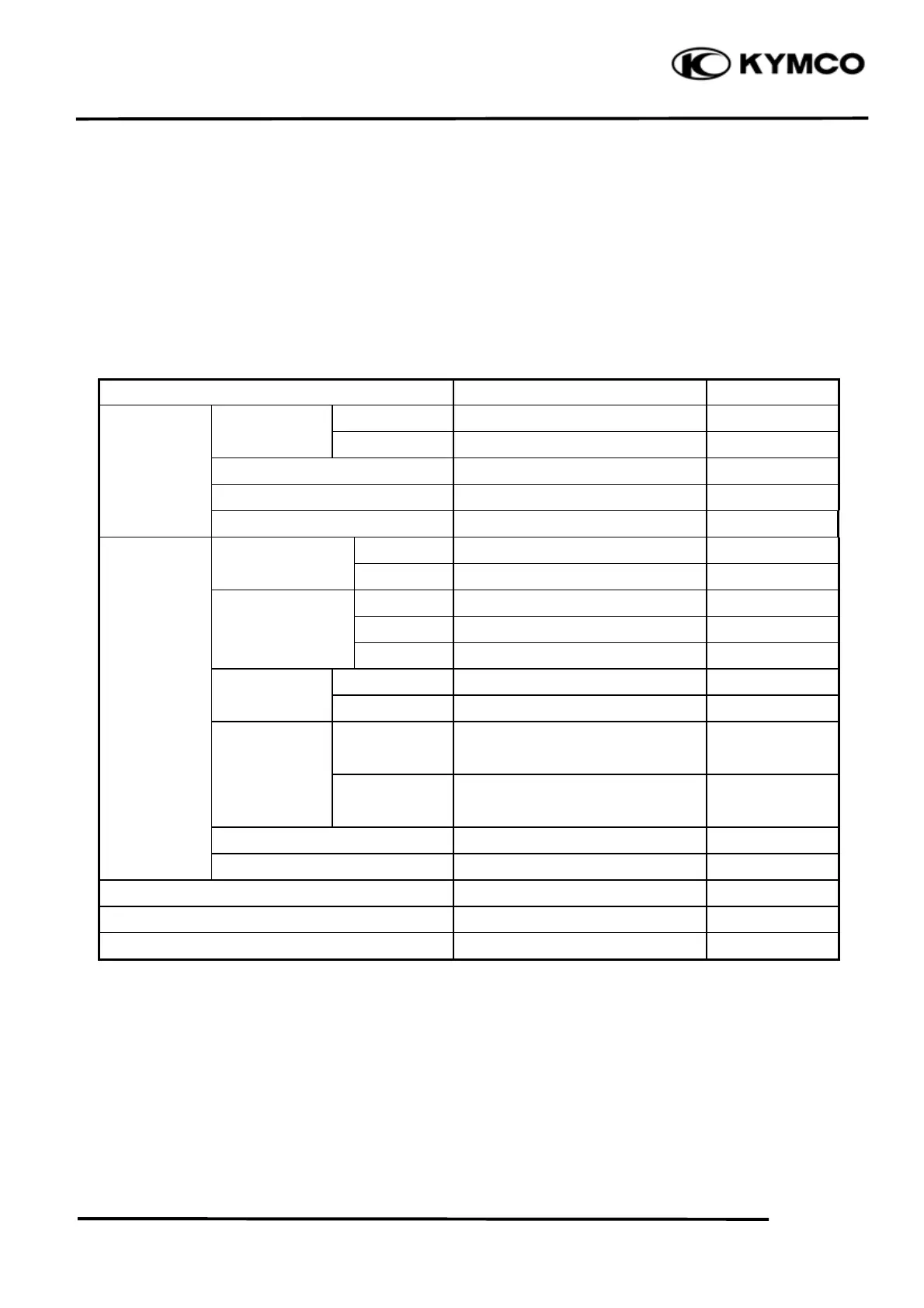

SPECIFICATIONS

Unit: mm (in)

Ite

Service Limit

DINK 200i 62Д62.015 (2.48Д2.4806) 62.1 (2.484)

I.D.

DINK 125 52.4Д52.41 (2.096Д2.0964) 52.5 (2.1)

Warpage

!

0.05 (0.002)

Cylindricity

!

0.05 (0.002)

Cylinder

True roundness

!

0.05 (0.002)

Ring-to-groove Top

0.015Д0.05 (0.006Д0.002) 0.09 (0.0036)

clearance

Second

0.015Д0.05 (0.006Д0.002) 0.09 (0.0036)

Top

0.15Д0.3 (0.006Д0.012) 0.5 (0.02)

Ring end gap Second

0.15Д0.3 (0.006Д0.012) 0.5 (0.02)

Oil side rail

0.2Д0.9 (0.008Д0.036)

!

DINK 200i

61.995Д61.975 (2.4878Д2.479) 61.9 (2.476)

Piston O.D.

DINK 125

52.37Д52.39 (2.0948Д2.0956) 52.3 (2.092)

DINK 200i

5 mm (0.2 in) from bottom of skirt !

Piston O.D.

measuring

position

DINK 125

9 mm (0.36 in) from bottom of skirt !

Piston-to-cylinder clearance

0.01Д0.04 (0.0004Д0.0016) 0.1 (0.004)

Piston,

piston ring

Piston pin hole I.D.

15.002Д15.008 (0.60008Д0.6

0032) 15.04 (0.6016)

Piston pin O.D

14.994Д15 (0.59976Д0.6) 14.96 (0.5984)

Piston-to-piston pin clearance

0.002Д0.014 (0.00008Д0.00056) 0.02 (0.0008)

Connecting rod small end I.D. bore

15.016Д15.034 (0.60064Д0.60136) 15.06 (0.6024)

Loading...

Loading...