3. INSPECTION/ADJUSTMENT

3-17

DINK 200i125

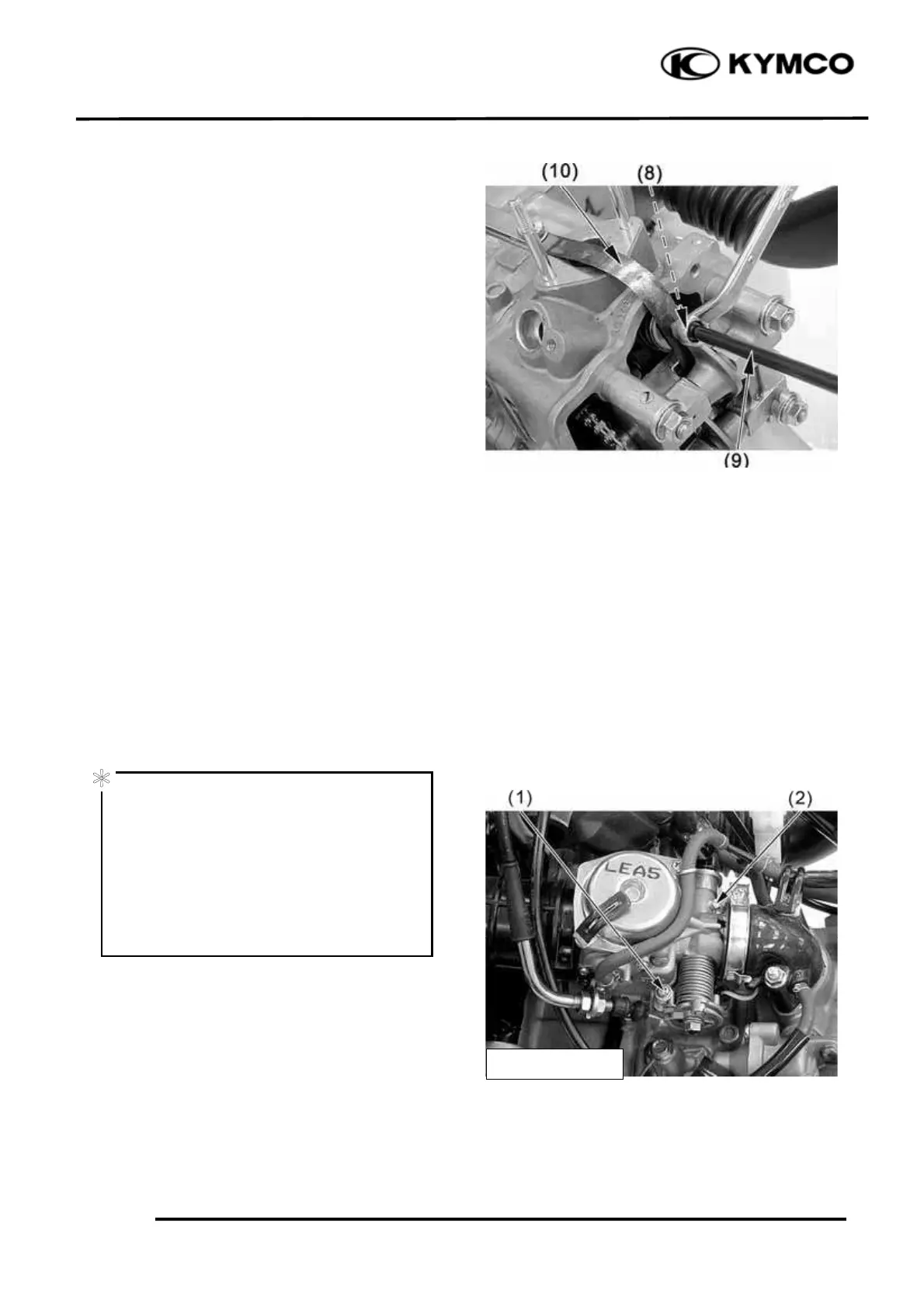

Adjust by loosening the valve adjusting screw

lock-nut (8) and turning the adjusting screw

(9) until there is a slight drag on the thickness

gauge (10).

Valve Clearance: IN: 0.1 mm (0.004 in)

EX: 0.1 mm (0.004 in)

Apply oil to the valve adjusting screw lock-

nut threads and seating surface.

Hold the adjusting screw and tighten the lock

nut to the specified torque.

Torque: 0.9 kgf-m (9 N-m, 6.5 lbf-ft)

Special tool:

Valve adjuster A120E00036

After tightening the lock-nut, recheck the

valve clearance.

Install the removed parts in the reverse order

of removal.

IDLE SPEED

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw (1) to obtain the

specified idle speed.

Idle Speed:

DINK 125: 1700 rpm

DINK 200i: 1660 rpm

DINK 125 only:

When the engine misses or run erratic, adjust

the pilot screw (2).

The engine must be warm for accurate

idle speed inspection and adjustment.

It is not necessary to adjust idle speed

for DINK 200i. The throttle body is

factory pre-set, do not loosen or tighten

the painted bolts and screws of throttle

body. Loosening or tightening them

can cause throttle and idle and valve

synchronization failure.

Ϡ

DINK 125 onl