English

48EN

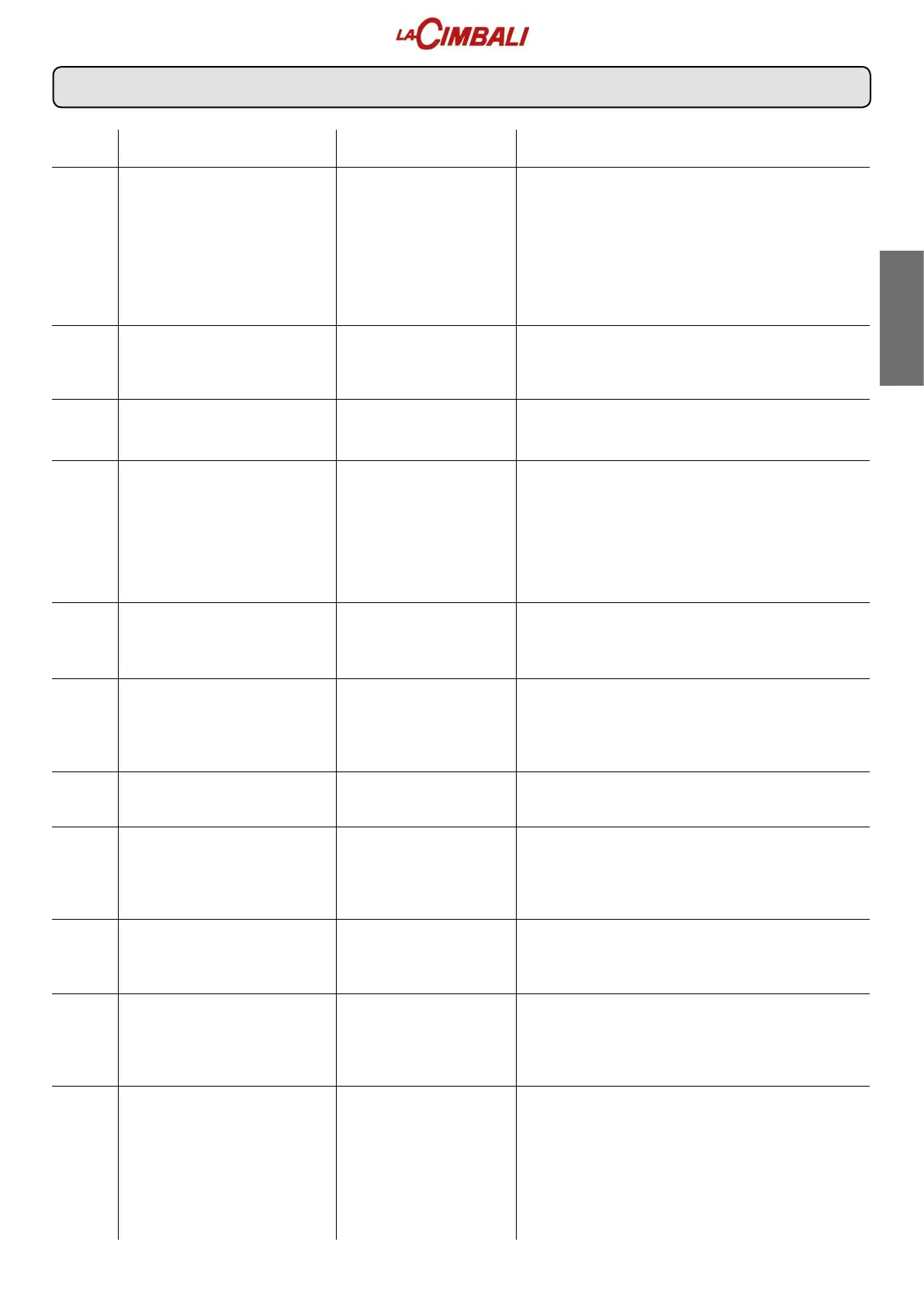

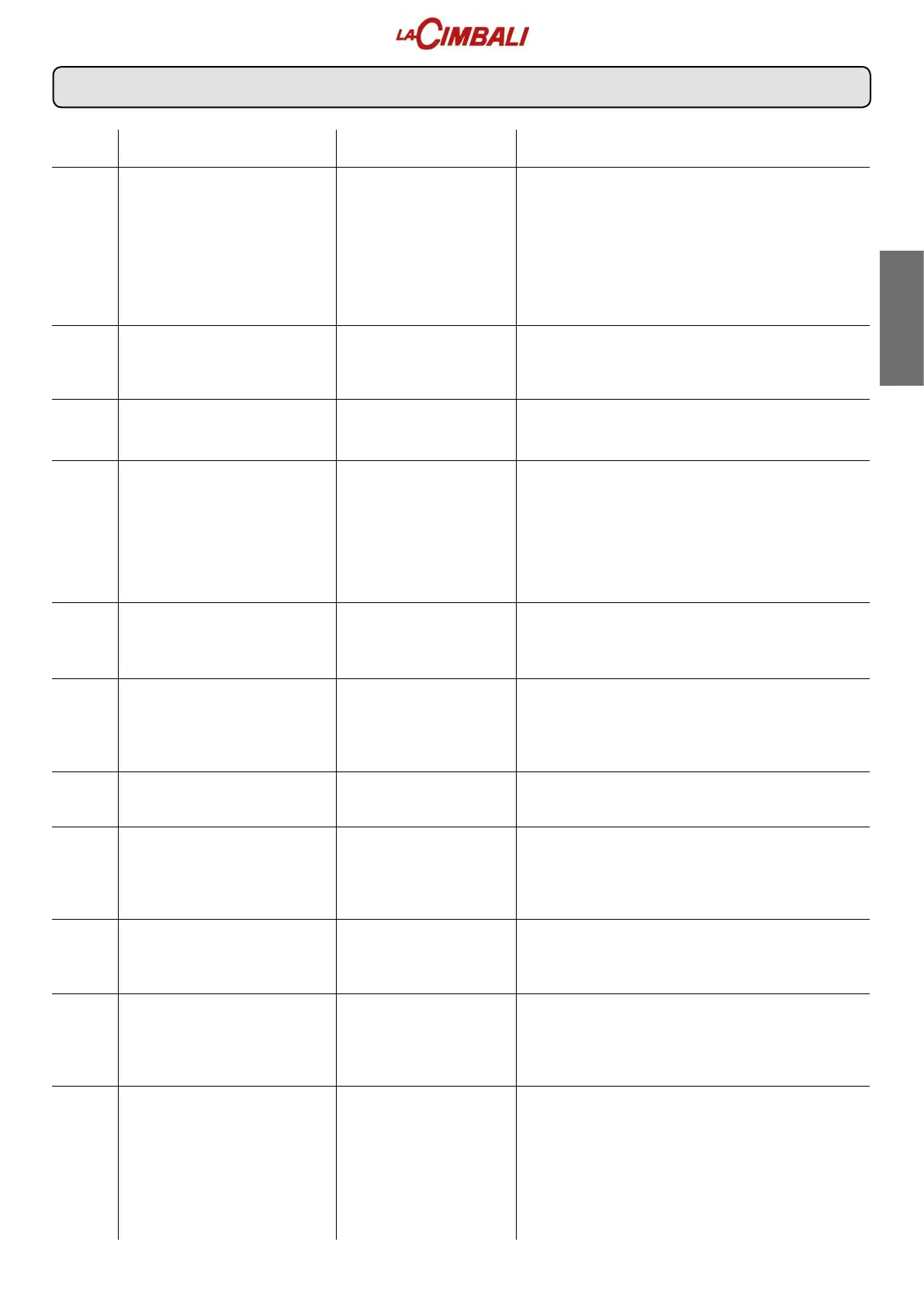

12. Diagnostic messages

MALFUN.

CODE

VERIFICATIONS and SOLUTIONSPOSSIBLE CAUSESDESCRIPTION

USB power-supply

malfunction.

Group boiler pressure sensor

x out of range (x = 1, 2, 3, 4)

Note: Group 1 is to the far left.

AC 24V power supply

malfunction.

Clock malfunction.

No power: group, EV, milk

pump

LCD display not connected

(applies only to machines

other than Emblem R and

M100).

Slave micro processor

malfunction.

Milk pump motor overcurrent

Temperature sensor signal

out of range.

Group boiler temperature

sensor x out of range

(x = 1, 2, 3, 4)

Note: Group 1 is to the far left.

Boiler heating timeout

- 45 minutes.

• USB-port current-

consumption too high.

• Sensor failure

• Card failure.

•The glass fuse on the

CPUboardislikelybroken.

• Contacts oxidised.

•Deadbattery.

• Clock blocked.

• Voltage drop in the

powersupply

• Break in cabling.

•Displayfault.

• Consequence of applied

force

• Rotor blocked

• Pumpmotorfaulty

• Sensor failure

• Card failure.

• Thermocuple

disconnected

• Sensor failure.

•Thesafetythermocouple

has been triggered

• The resistance is

interrupted (cabling

defect)

• The Triac card is

malfunctioning.

• Check the status of the USB port and its

connectionsinordertoidentifypossiblecausesof

excessive consumption (e.g. short-circuit).

•Oncethecauseofthemalfunctionisxedthe

USBportshouldrestoreitselfautomaticallyand

return to normal operation.

•Iftheproblempersists,replacetheCPUboard.

• Check cabling

• Replace the sensor

• Replace the card.

• Replace the fuse.

•Cleanthecontactsonthebattery.

•Measurethevoltageofthebattery(3VDC)and,

ifnecessary,replaceit.

IfthebatteryisOKtry,withthemachineturnedoff,

to remove it from the board and wait 2-3 minutes.

Thenreinsertthebatteryandcheckthattheclock

isworkingproperly.

• Check if CPU card has power.

•Checkpowersupplyunit(protection)

• Check cabling

• Check cabling.

•Iftheproblempersists,replacetheNewtonboard.

• Check wiring.

• Check whether the circuit or pump is clogged.

• Replace the pump.

• Check cabling

• Replace the sensor

• Replace the card.

• Check cabling

• Replace the sensor.

•Checkifthesafetythermostathasbeentriggered,

andresetitifnecessary

• Check if there are interruptions or detached

fastons on the cabling

• Check that the boiler resistance is not interrupted

and replaceitifnecessary

• Replace the Triac card.

020

(x)21*

023

024

025*

029 *

030

041*

051

(x)51*

052

Loading...

Loading...