95

5 Functional Description with Process Diagrams

5.2.6 Valve Leakage Test

NOTICE

The gas pressure test switch and design and volume of the test section pipework must be set

and designed such that the valve test system reliably detects even the smallest gas leakage

by the valve testing system at maximum combustion thermal output.

EN1648 requires a minimum gas leakage of 0.1% volume in relation to the gas flow rate at

maximum combustion thermal output, but at least 50 dm

3

/hr.

5.2.6.1 Requirements

NOTICE

The function must be mapped.

The pressure switch between the 2 main valves must be mapped either for valve leakage test

or gas pressure min. and valve leakage test.

5.2.6.2 Required Parameters

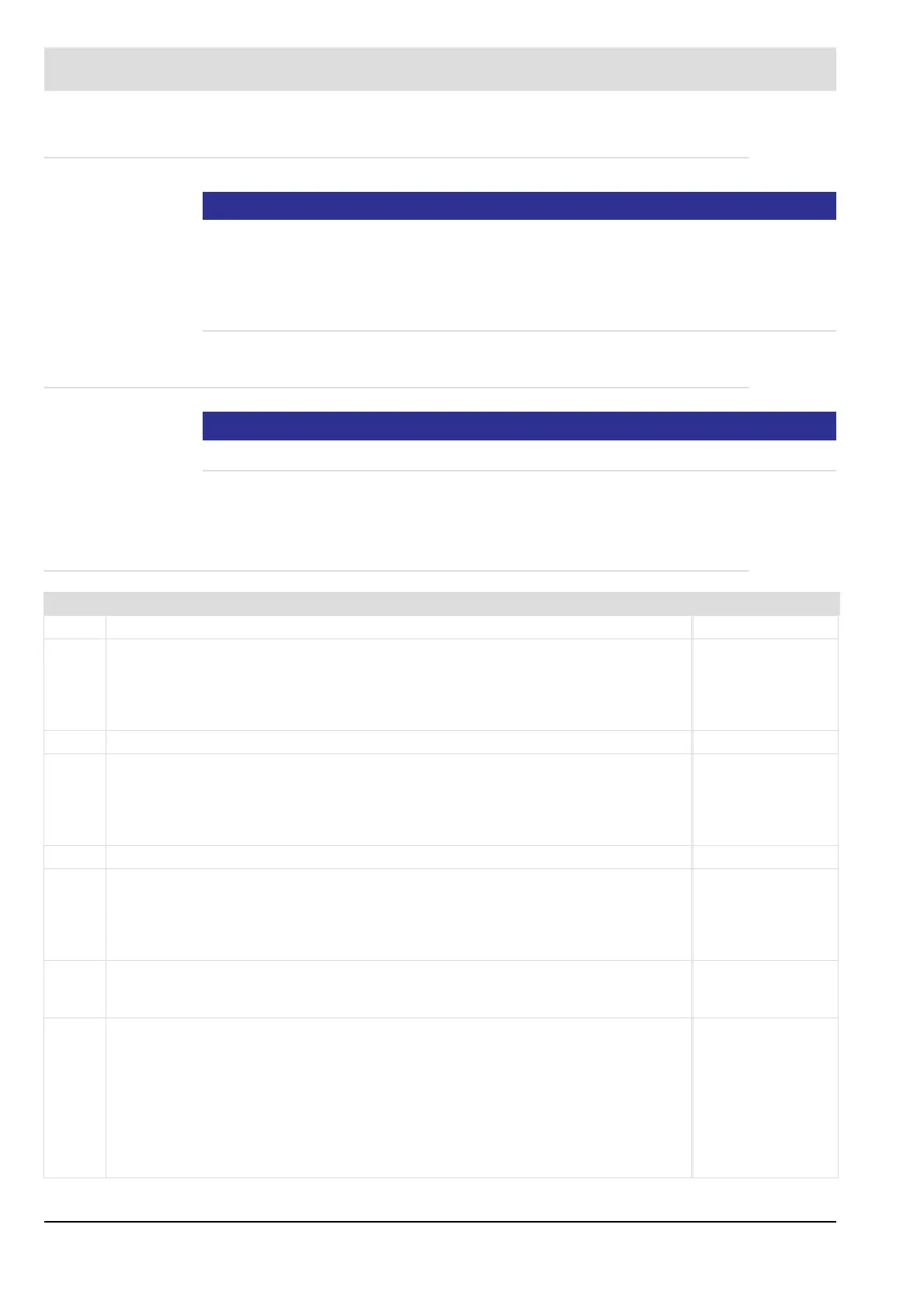

P no. Description Attributes

311 Valve leakage test before burner start-up [0.1 s] V1.0.0.0

Configured duration of the valve leakage test in 0.1 s Write: 1/GUI/UI

Read: 0

Default: 200

Min.: 50

Max.: 9999

313 Fill time of the valve leakage test [0.1 s] V1.0.0.0

Fill time of the valve leakage test in 0.1 s Write: 4/GUI/UI

Read: 0

Default: 20

Min.: 20

Max.: 50

334 Block and bleed time of valve leakage test line [0.1 s] V1.0.0.0

Time in 0.1 s for which the gas valve 2 is opened for block and bleed of the valve leakage

test line.

Write: 0/GUI/UI

Read: 0

Default: 10

Min.: 0

Max.: 25

802 Type of valve leakage test (0–none; 1–together with pre-purge; 2–after pre-purge is com-

pleted; 4–after burner operation; 5–before operation together with the pre-purge; 6–before

operation after pre-purge is completed)

V1.0.0.0

Type of valve leakage test:

0: no valve leakage test

1: valve leakage test starts together with the pre-purge

2: valve leakage test starts after pre-purge is completed

4: valve leakage test after burner operation

5: valve leakage test before operation starts together with pre-purge and after burner

operation

6: valve leakage test before operation starts after pre-purge is completed and after burner

operation

Write: 1/GUI/UI

Read: 0

Default: 0,1,0,0

Min.: 0

Max.: 7

Loading...

Loading...