Grove Published 3-23-2020, Control # 654-04 5-9

GRT655/655L OPERATOR MANUAL SET-UP AND INSTALLATION

7. Verify display of main boom length agrees with actual

boom length.

8. Verify display of main boom angle agrees with actual

boom angles.

9. Verify display of the crane operating radius agrees with

the actual radius.

10. Verify load display by lifting a load of known weight.

Load display accuracy must be within the tolerance

range.

HOIST ROPE REEVING

NOTE: 35 x 7 (rotation resistant) wire rope is used on this

crane.

Within load and range chart limits and permissible line pull,

multi-part lines allow the operator to raise a greater load than

can be raised with a single part line. Various hoist rope

reeving (part line) is possible with the boom nose and hook

block (Figure 5-10 and Figure 5-15). Reeving should be

done by a qualified rigger using standard rigging procedures.

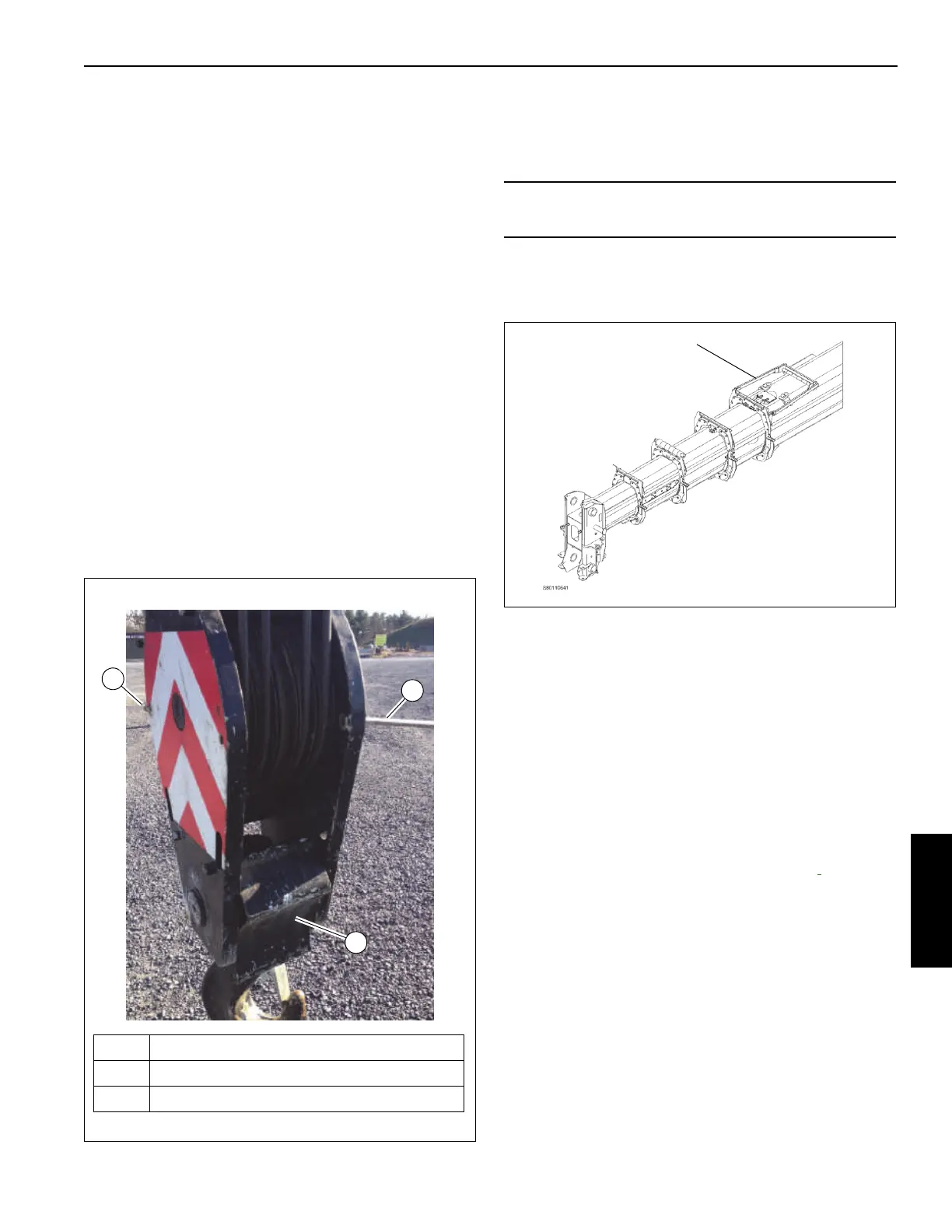

To quick reeve the hook block without removing the wedge

socket on end of hoist rope, remove the retaining clips from

the two pins (1, Figure 5-10), then drop the two rope guards

(2) to their lowered position.

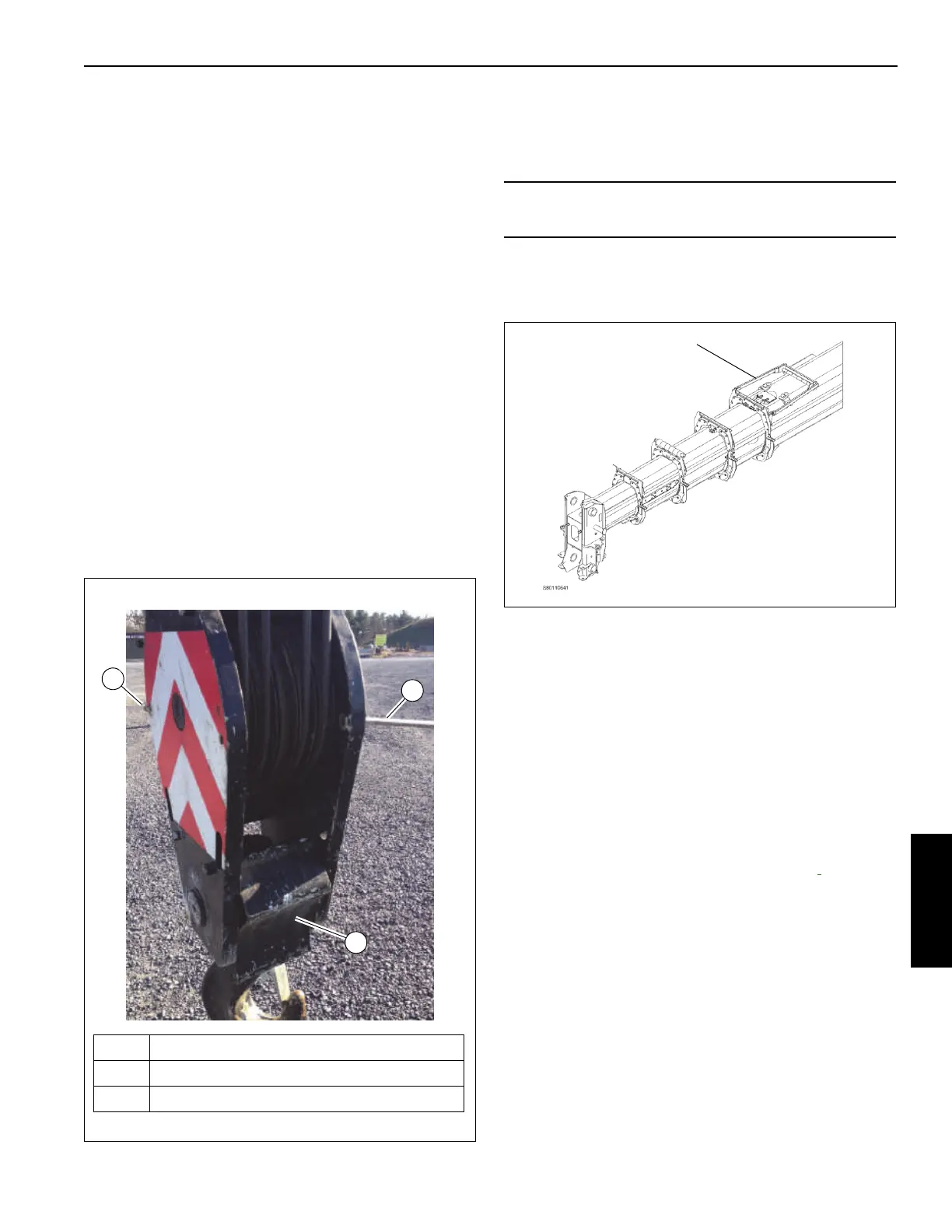

Reeving Hoist Rope Over the Boom

For cranes equipped with a rope guide, obey the following

instruction.

Always reeve main hoist rope through rope guide

(1, Figure 5-11). Always reeve auxiliary hoist rope outside

rope guide.

DEAD-END RIGGING/WEDGE SOCKETS

Wedge socket assemblies are popular rigging accessories

used for decades to terminate wire ropes on mobile cranes.

A wedge socket assembly is easily installed and dismantled,

but must be installed and used correctly. Use only a wedge

and socket of the correct size for the rope fitted. Failure to do

so may result in rope pulling through fitting.

Since state and local laws may vary, alternate attachment

methods may be necessary depending upon work

conditions. If alternate methods are selected, the user is

responsible and should proceed in compliance with the

regulations in force. If there are any questions, contact your

local Grove distributor or Manitowoc Crane Care.

Do not mix components from different manufacturers. The

selection, installation, and use of a wedge socket assembly

must be in accordance with requirements of the wedge

socket manufacturer and wire rope manufacturer upon

whose wire rope the wedge socket assembly will be used.

Grove specifies size, type, class, and line pulls for wire rope;

predominately rotation resistant wire rope, and rigging

accessories such as overhaul balls and hook blocks for use

with each new crane it manufactures.

Other wire ropes and rigging accessories are available from

various vendors. Different wire rope manufacturers have

differing requirements for construction, handling, cutting,

seizing, installation, termination, inspection, and

FIGURE 5-10

Item Description

1Pin

2 Rope Guard

1

1

2

CAUTION

Do not reeve auxiliary hoist rope through the rope guide.

Loading...

Loading...