OPERATING CONTROLS AND PROCEDURES MLC300 OPERATOR MANUAL

3-68

Published 11-20-19, Control # 234-19

Boom Hoist Operation

The location of the boom control handle varies depending on

the crane’s configuration. Refer to Drum and Control Handle

Identification on page 3-54.

1. If not already done, perform the crane Startup

Procedure on page 3-63

.

2. Select the correct capacity chart and crane configuration

using the RCL/RCI Display. For detailed instructions,

see the RCL/RCI Operation Manual.

3. Boom hoist speed can be adjusted between 25% and

100% to meet operator needs. See the Speed and

Limits Screen topic in the Main Display Operation

Manual for detailed instructions.

4. Make sure the automatic boom stop is set at the proper

angle. For detailed instructions, see the Automatic

Boom Stop Adjustment topic in Section 4 of the MLC300

Service Manual.

5. Turn off the boom hoist park switch. It may be necessary

to raise the boom slightly to disengage the boom hoist

pawl.

6. Increase the engine speed to the desired RPM with the

hand throttle. Press the foot throttle to momentarily

increase the engine speed when more power is

required.

NOTE The VPC setup mode must be ON anytime the boom

is suspended and operated out of the capacity chart.

The VPC Setup Required fault will come and you will

not be able to operate the boom hoist until this step is

taken.

The VPC setup mode must be OFF anytime the

boom is suspended and operated within the capacity

chart. The VPC Setup Prohibited fault will come and

you will not be able to operate the boom hoist until

this step is taken.

7. Pull the boom control handle BACK from off to RAISE

the boom.

8. Push the boom control handle FORWARD from off to

LOWER the boom.

9. As the boom nears the desired angle, slowly move the

boom control handle toward off to decrease speed.

Then, move the control handle to off to stop the boom

when it reaches the desired angle. The boom hoist

brake will apply to hold the boom in position.

NOTE Besides the boom maximum up limit, a physical

boom stop is provided. The physical boom stop

cushions boom raising between approximately 75°

and the maximum boom angle. The boom stop also

provides a physical stop at 89°.

10. To hold the boom in position for long periods, turn on the

boom park switch. The boom hoist pawl will engage.

CAUTION

Avoid Rigging Damage

Check that the boom hoist wire rope is reeved through all

sheaves and spooled properly onto the drum before

raising the boom from the ground.

• For wire rope and reeving specifications, see the

Boom Assembly Drawing in Section 4 of the MLC300

Operator Manual.

• For instructions on attaching the wire rope to boom

hoist drum, see the Wire Rope Installation topic in

Section 4 of the MLC300 Operator Manual.

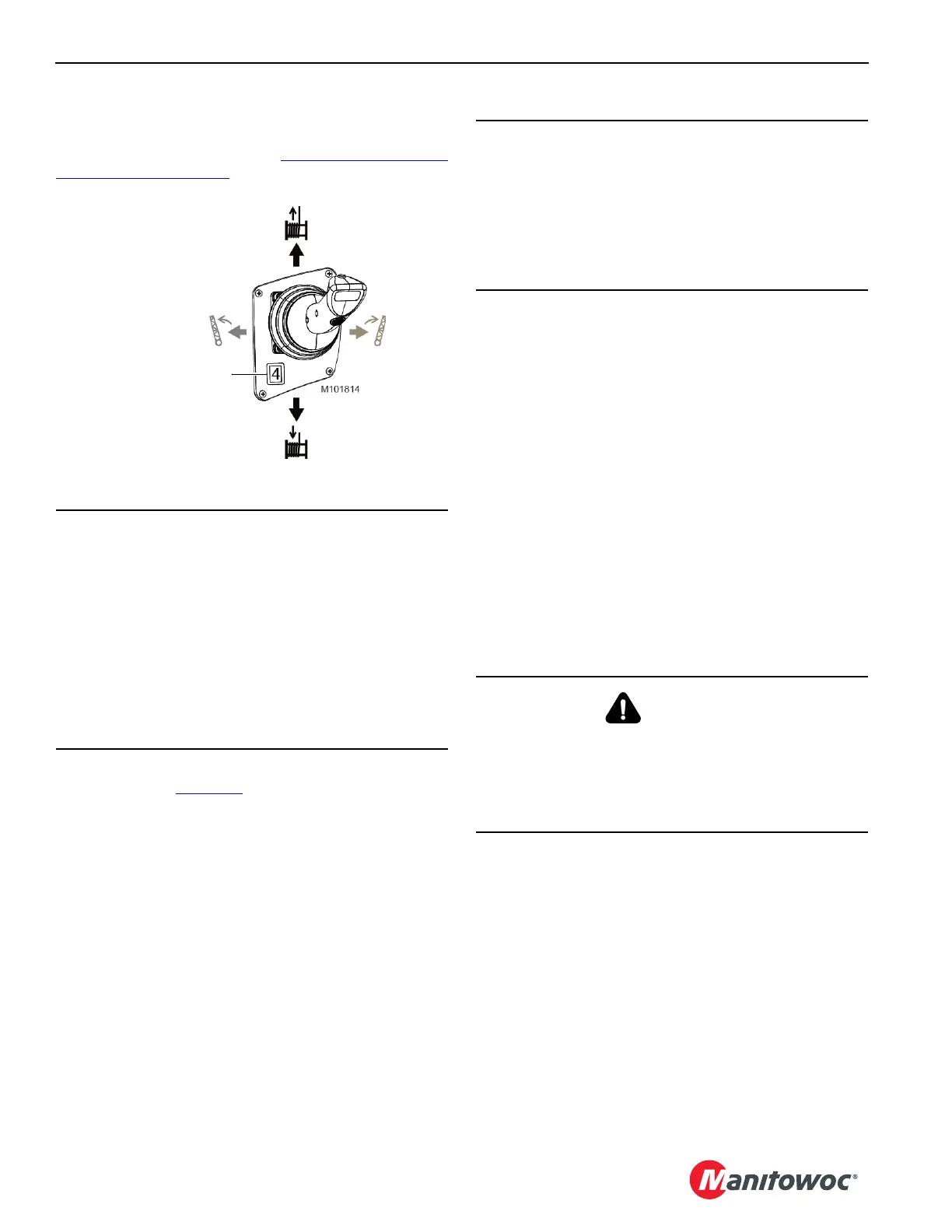

Figure 3-18. Boom and Swing Control Handle

Drum 4 – Boom Hoist

CAUTION

Avoid Boom or Luffing Jib Damage

Do not turn on the drum park switch while raising or

lowering the boom. The brake will bring the boom to an

abrupt stop. This action could cause shock load damage

to the boom and the jib. Bring the boom to a smooth stop

with the control handle and then turn on the drum park

switch.

WARNING

Avoid Two-Blocking Hazard

Pay out the load lines while lowering the boom. The load

may contact the boom point sheaves or the jib point

sheaves if this step is not taken. The wire rope or other

parts could break, allowing the load to fall.

Loading...

Loading...