Manitowoc Published 11-20-19, Control # 234-19 4-3

MLC300 OPERATOR MANUAL SETUP AND INSTALLATION

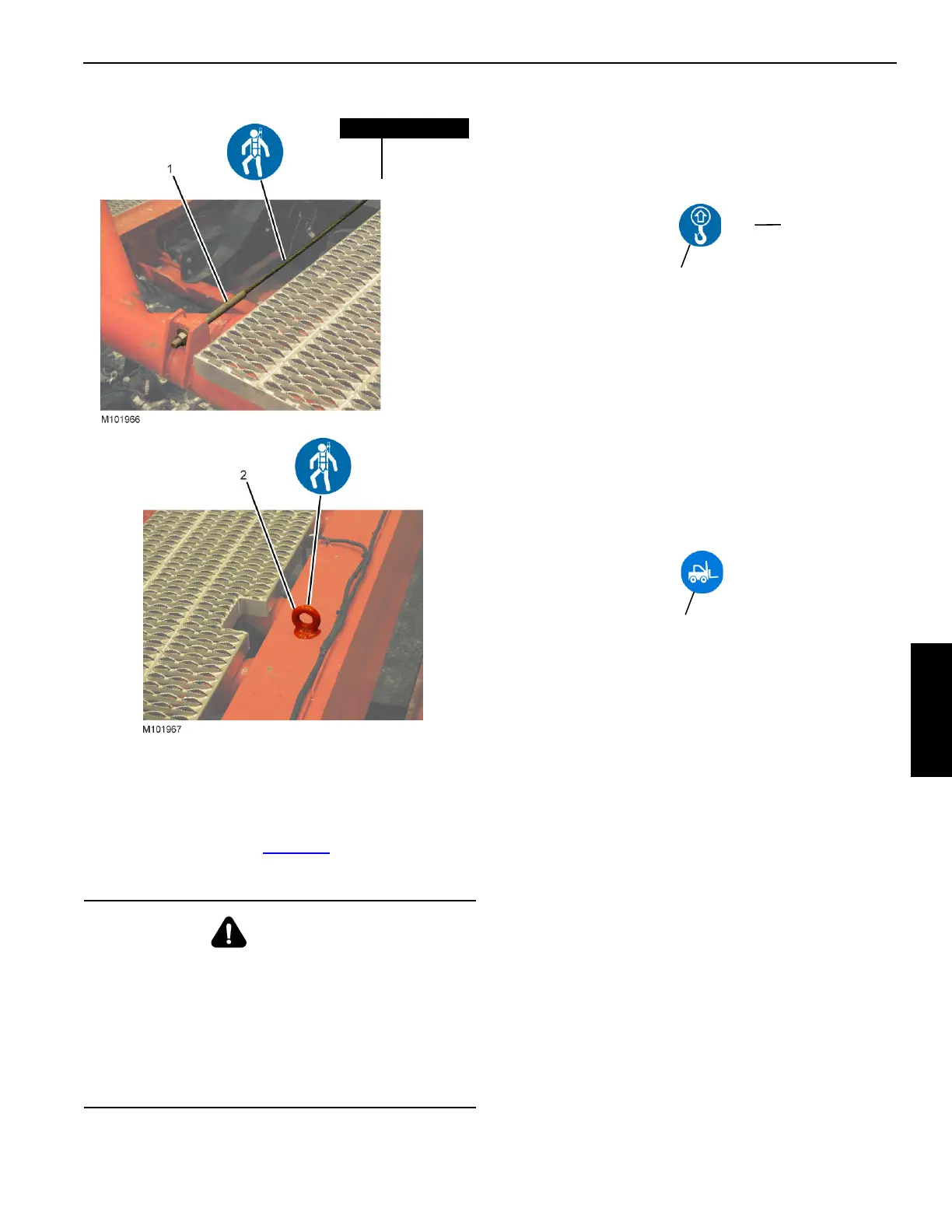

PERSONAL FALL-PROTECTION

Manitowoc has provided lifelines and anchors throughout the

crane and attachment (see Figure 4-1

) to which workers can

attach their personal fall-protection equipment.

HANDLING COMPONENTS

The major components are equipped with lifting lugs. The

lifting lugs are identified by the following symbol in the

assembly and disassembly illustrations.

When lifting lugs are not provided, use nylon lifting slings to

lift the components. If wire rope or chain slings are used,

install protective covering (such as sections of rubber tire)

between slings and component being lifted.

It is the crane owner’s/user’s responsibility to ensure that all

lifting slings, hooks, and shackles are in safe working order

and capable of handling the load applied to them.

In some cases, a forklift is required to lift components. When

required, the lift points are identified by the following symbol

in the assembly and disassembly illustrations.

RETAINING CONNECTING PINS

Connecting pins are retained in various ways:

• Wire-lock pins

• Quick-release pins

• Cotter pins

• Hitch Pins

• Safety pins

• Keeper plates with cap screws and lock washers

Do not operate the crane until all connecting pins are

installed and properly retained.

CRANE WEIGHTS AND SHIPPING DATA

See the Crane Weights topic in Section 1 of this manual for

the weights of individual crane components.

See the MLC300 Product Guide in Section 1 of this manual

for outline and shipping dimensions.

WARNING

Fall Hazard!

To prevent falling from any height during crane assembly

and disassembly, personnel shall wear fall-protection

equipment.

• Anchors and lifelines are designed to handle only one

person at a time.

• Do not use anchors for lifting or pulling loads.

Figure 4-1

Item Description

1 Lifeline

2 Anchor

(4)

Lifting Point

Symbol

Number of

Lifting Points

Figure 4-2

Forklift Symbol

Figure 4-3

Loading...

Loading...