Manitowoc Published 11-20-19, Control # 234-19 2-27

MLC300 OPERATOR MANUAL SAFETY INFORMATION

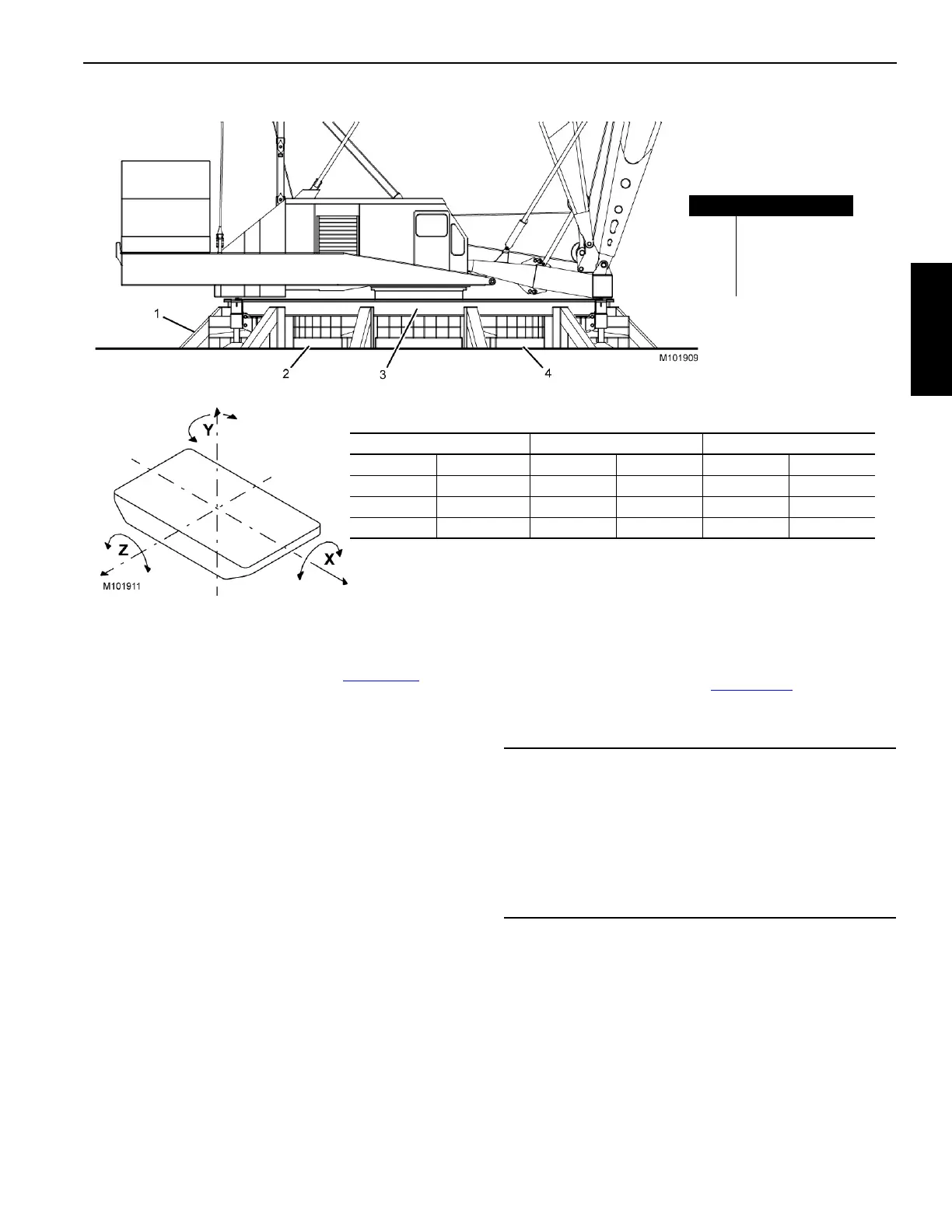

3. RINGER

®

(crawler mounted, carbody mounted)

supported on blocking, screw jacks, or steel pedestals

which are braced and fastened to the foundation in such

a manner as to prevent movement (Figure 2-10

).

NOTE RINGERS must be equipped with hook rollers on

the boom carrier and the counterweight carrier.

4. RINGER (platform mounted) which has the ring braced

and fastened directly to the foundation in such a manner

as to prevent movement.

Capacity Charts for Barge Mounted Crane

Manitowoc provides two types of Capacity Charts for a crane

mounted on a barge or other supporting structure under

static conditions.

1. A Capacity Chart based on tipping when the crane is

anchored only to prevent shifting.

2. A Capacity Chart based on structural competence when

the crane is securely fastened for use as a pedestal

mounted crane.

NOTE Unless otherwise specified in a machine list

Capacity Chart, a 0 degree machine list Capacity

Chart rating applies to machine list not to exceed

1/2 degree. All other machine list ratings – 1°, 2°,

and 3° – must NOT be exceeded.

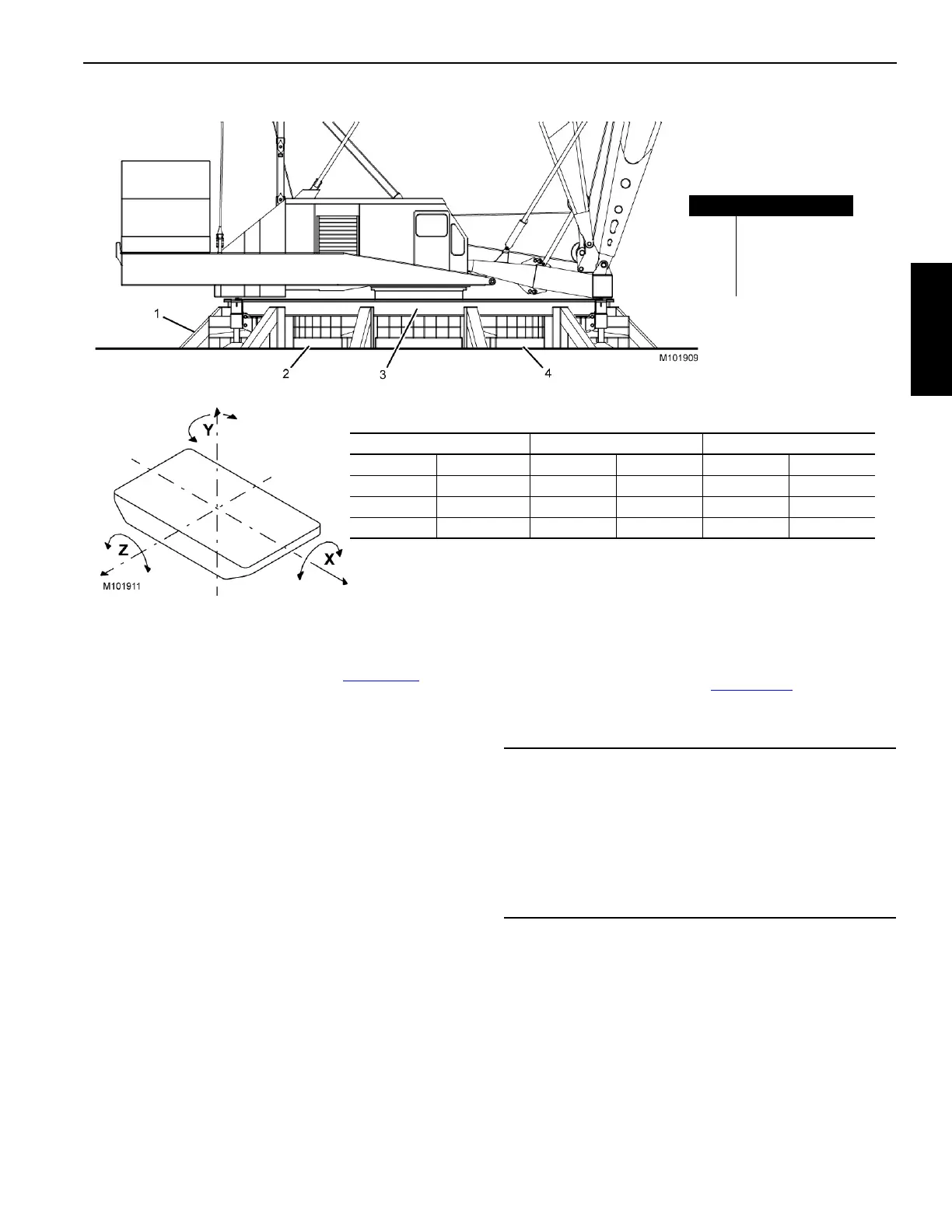

Shock Loading Caused by Barge Dynamics

Shock loads to the crane can be experienced when the

barge is subjected to up and down movement of wave action

(referred to as DYNAMICS). Figure 2-11

illustrates the

dynamic conditions of the barge which influence crane

capacity.

NOTE Manitowoc does not recommend crane operation

under dynamic conditions.

Operation on Barge

Machine list and/or dynamics will be experienced when a

crane is operated on a barge, ship, or floating platform. Both

of these conditions reduce the crane’s capacity and each

must be taken into account for safe operation on a barge,

ship, or floating platform.

Figure 2-10. RINGER-Mounted-Crane

Item Description

1Bracing

2 Ring Support

3 Ring Assembly

4 Foundation

Figure 2-11. Barge Dynamics

AXIS TRANSITIONAL ROTATIONAL

SYMBOL NAME STATIC DYNAMIC STATIC DYNAMIC

X Longitudinal Surge Heel List Roll

Y Vertical Heave Yaw

Z Lateral Sway Trim Pitch

CAUTION

Structural Damage Hazard!

If the crane’s boom or structure is shock loaded during

operation, or there is any indication of shock loading, all

structural components of the crane must be inspected to

detect cracks and other damage. Nondestructive test

equipment, such as magnetic particle or ultrasonic

procedures, is recommended for this inspection.

Loading...

Loading...