Manitowoc Published 04-06-18, Control # 231-14 4-93

MLC650 VPC-MAX™ OPERATOR MANUAL SET-UP AND INSTALLATION

LOAD LINE REEVING

NOTE: The boom top can be reeved in various

configurations. See the reeving diagrams included

at the end of this section for each reeving option.

Guide Sheaves and Drums

See Figure 4-78 for identification of the load drums and the

guide sheaves.

Refer to the Reeving Diagrams at the end of this section for

rope routing over the boom top wire rope guide (7).

Once the wire rope is routed through the guide sheaves,

install all the rope guard pins, bars, and rollers to retain the

wire rope on the sheaves. Wire rope and sheaves can be

damaged if the rope is not properly retained on sheaves.

Load Block Identification

See the Boom Rigging Drawing at the end of this section for

a complete list of load blocks and hook and weight balls

available for use with this crane.

NOTE: Reference the block drawings included at the end

of this section for block assembly configurations.

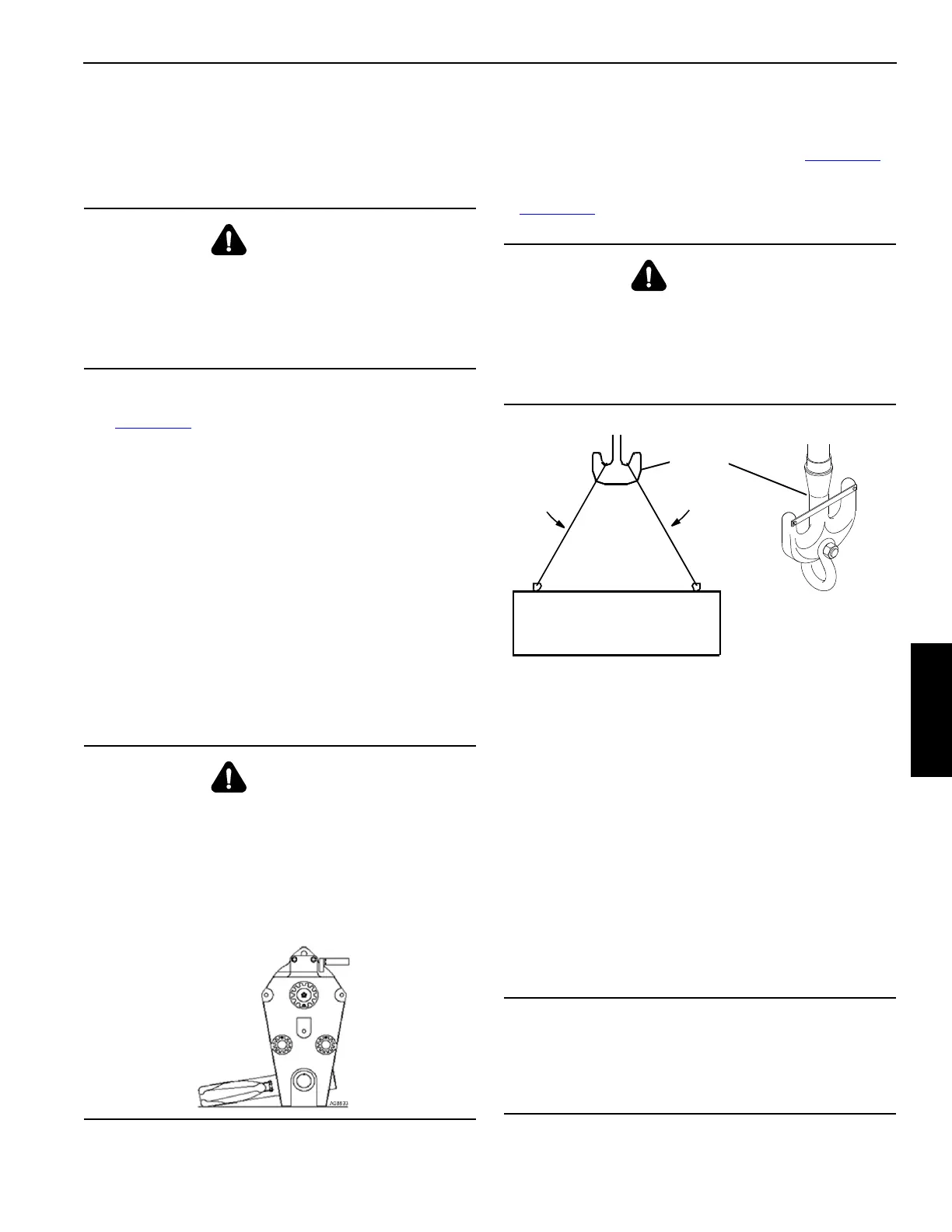

Duplex Hook

Attach the load so it is balanced equally on the hook. The

lifting slings must be within the angles given in Figure 4-78

to

achieve maximum hook capacity. The duplex hook has a

hole to which an optional shackle can be attached as shown

in Figure 4-78

.

Wire Rope Specifications

Refer to the Wire Rope Specifications chart in the Capacity

Chart Manual for:

Parts of the line required to handle desired load

Wire rope length required for various boom lengths and parts

of line

Maximum spooling capacity of load drums

Load Block Reeving

For reeving of the lower boom point, see the Reeving

Diagrams at the end of this section.

Reeving in any manner other than shown can result in

excessive block twist.

WARNING

Falling Load Hazard!

Use only a load block or hook and weight ball with a

capacity equal to or greater than load to be handled.

The load block can fail if overloaded, allowing the load to

fall.

WARNING

Avoid Death or Serious Injury!

Exercise care when block is standing in vertical position,

as the potential for tipping exists. Potential causes of

tipping are unstable work area, boom movement and the

reeving process.

If work area is unstable, lay block flat on side plate.

WARNING

Falling Load Hazard!

Limit load to be handled with shackle to capacity of load

block or shackle, whichever is less.

Load block or shackle can fail if overloaded, allowing load

to fall.

CAUTION

Wire Rope Damage!

Do not hoist the load block closer to the boom point than

shown in the reeving diagrams. Improper fleet angle or

contact with other parts can damage the wire rope.

Loading...

Loading...