Manitowoc Published 04-06-18, Control # 231-14 4-17

MLC650 VPC-MAX™ OPERATOR MANUAL SET-UP AND INSTALLATION

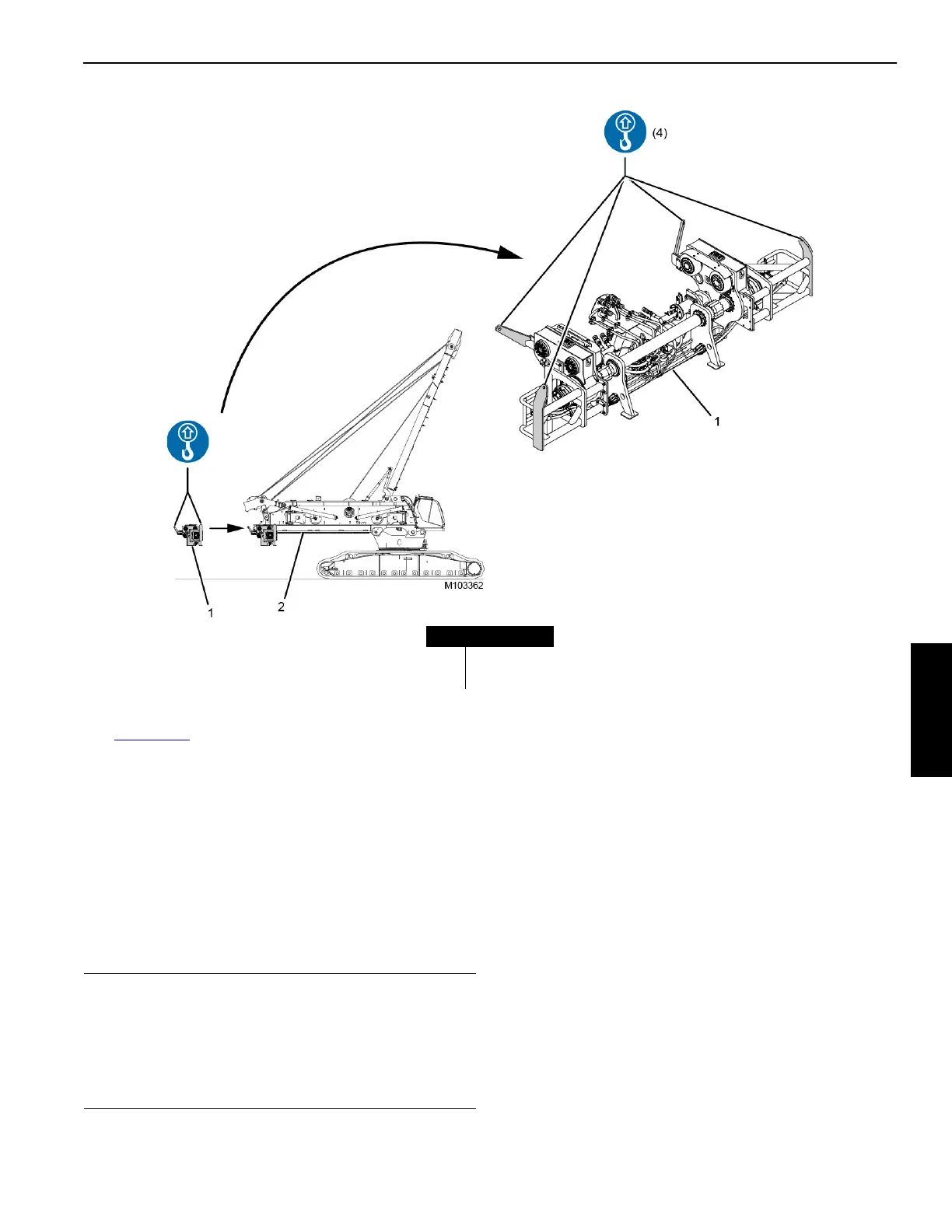

See Figure 4-19 for the following procedure.

2. Using the plates and pendants, attach the actuator (1) to

the assist crane.

NOTE: Any additional rigging used between the assist

crane hook block and plates must not exceed

3,6 m (12 ft) in length. The actuator should hang at

a 2° angle with the rear rollers higher than the front

rollers.

3. Have assistants use the taglines to help control the

movement of the actuator and to help guide it onto the

rotating bed.

4. Using the assist crane, position the actuator at the rear

of the rotating bed (2) so the front (vertical) rollers

contact the roller wear plates.

5. Using the assist crane, adjust the actuator to be

horizontal.

6. Using the assist crane, draw the actuator onto the

rotating bed to a point where the side rollers on the

actuator contacting the sides (edge) of the rotating bed.

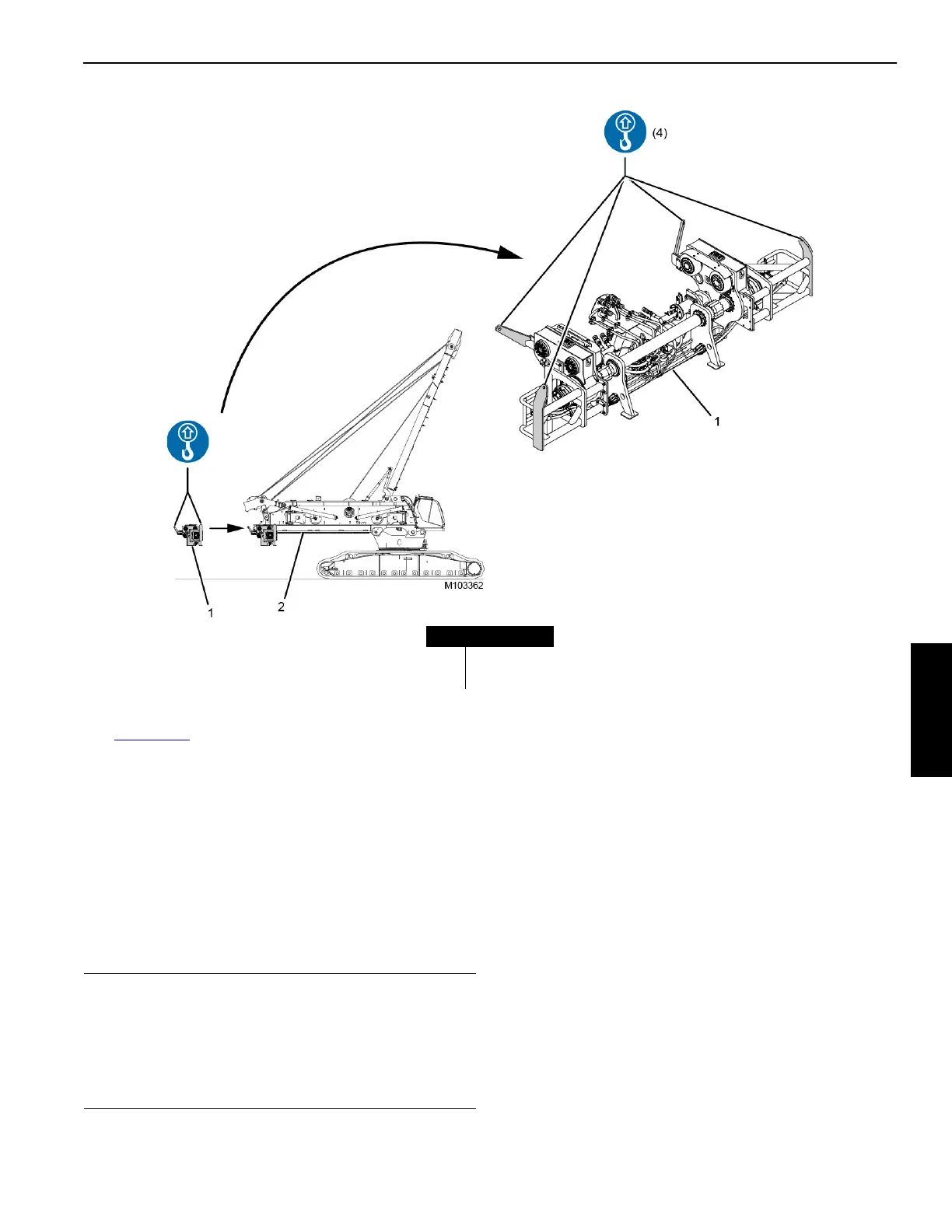

Aligning the Actuator

Precise actuator alignment is required in order to install the

actuator beyond the point where the side rollers first contact

the rotating bed.

To properly align the actuator to the rotating bed, use the

assist crane to slowly draw the actuator farther onto the

rotating bed until the rear (vertical) rollers contact the wear

plates.

During this process, the rear rollers contact and roll over the

small rear bolt-on stop blocks.

FIGURE 4-19

Item Description

1Actuator

2 Rotating Bed

CAUTION

Equipment Damage!

The top of the actuator can be damaged if it is lifted too

high.

Make sure the rollers on the actuator maintain contact

with the roller wear plates.

Loading...

Loading...