Multiple devices, even of different types, can be connected to the STOP

SAFETYEDGEinputifappropriatelyorganised:

-NOdevices:connectthe8.2kΩresistorinparalleltothedevice;

-NCdevices:connectthe8.2kΩresistorinseriestothedevice;

- You can connect multiple NC devices “in series” with each other without

quantity limits;

-Iftherearemultipledevices,allmustbeconnected“incascade”withasingle

8.2kΩterminalresistance;

- You can also create a combination of NO and NC types, by placing the two

contacts“inparallel”.Inthiscase,youneedtoplacea8.2kΩresistance“in

series”withtheNCcontact;thisalsomakesitpossibletoputthreedevices

together:NO,NCand8.2KΩ.

3.7 - Connecting a radio receiver

The control unit has an SM connector for connecting an SMXI, SMXIS, OXI,

OXIT or similar radio receiver (optional accessory, not supplied).

To connect the radio receiver, you must disconnect the mains power supply

from the control unit and insert the receiver as shown in Fig. 8.

Table2showstheactionsperformedbythecontrolunitaccordingtotheacti-

vated outputs or the commands sent by the radio receiver.

Note - For further information, refer to the instruction manual for the receiver.

TABLE 2

SMXI, SMXIS Receiver in “Mode 1 or 2”

output description

Output No. 1 Step-by-Step

OutputNo.2

Partial open; factory setting: it opens to halfway (this

may be changed during the position acquisition phase

or by using the Oview programmer)

OutputNo.3 Open

OutputNo.4 Close

OXI, OXIT receiver programmed in “extended Mode 2”

command description

Command No. 1

Step-by-Step

CommandNo.2

Partial open; factory setting: it opens to halfway (this

may be changed during the position acquisition phase

or by using the Oview programmer)

CommandNo.3

Open

CommandNo.4

Close

Command No. 5

Stop

CommandNo.6

Step-by-Step Condominium

Command No. 7

Step-by-Step High priority

CommandNo.8

Partialopen2

CommandNo.9

Partialopen3

Command No. 10

Open and Lock automation

Command No. 11

Close and Lock automation

CommandNo.12

Lock automation

CommandNo.13

Release automation

CommandNo.14

Timed Courtesy light

Command No. 15

CourtesylightON/OFF

3.8 - Initial startup and electrical connections test

Aftersupplyingpowertothecontrolunit,carryoutthefollowingchecks:

•VerifythatthegreenL2LED(closetotheDIPswitches)ashesregularly,with

afrequencyof1ashpersecond.

•Ifthesystemisequippedwithphotocells,checkthattheirLEDsashcor-

rectly(RX);thetypeofashingisnotsignicantbecausethatdependsonother

factors.

•EnsurethattheredSAFETYLEDnearthekeyboardcableconnectorisper-

manentlyON(seeSafetyLEDDiagnosticstable,Paragraph6.2).

If any one of these tests fails to comply with requirements, you must discon-

nect the electrical power from the control unit and check the various electrical

connections made previously.

3.9 - Total deletion of the control unit memory

You can delete all the data stored on the control unit and restore it to its original

state with the default settings.

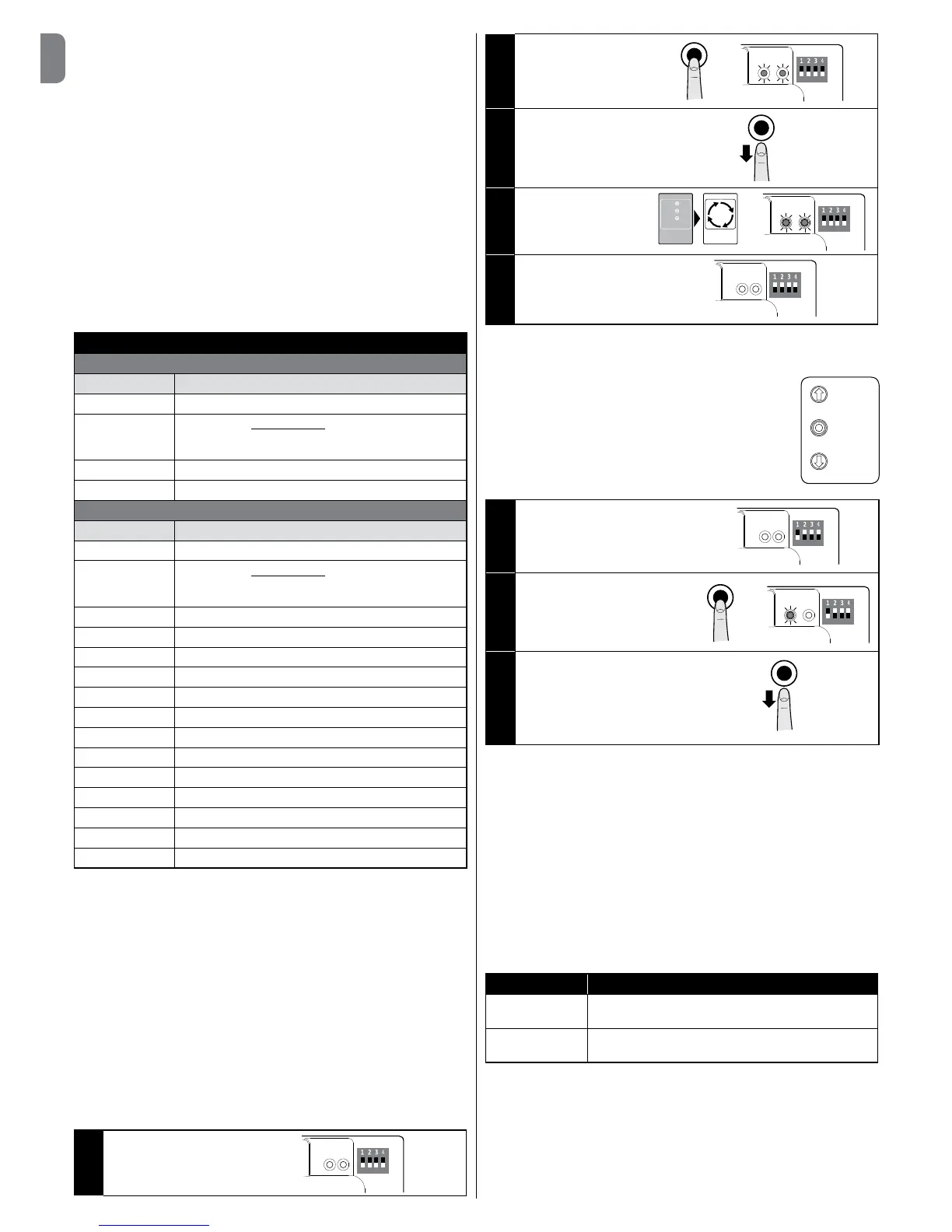

01. Setdipswitches1-2-3-

4toON=theredand

green ledsstartashing

quickly

ON

OFF

02. Press and hold the

STOPbuttonfor3sec.

until the green and red

leds remain lit

3”

ON

OFF

03. Release the STOP

button

04. At this point the control

unit performs a RESET

=theredandgreenleds

startashingquickly

ON

OFF

RESET

05. Setdipswitches1-2-3-

4toOFF

ON

OFF

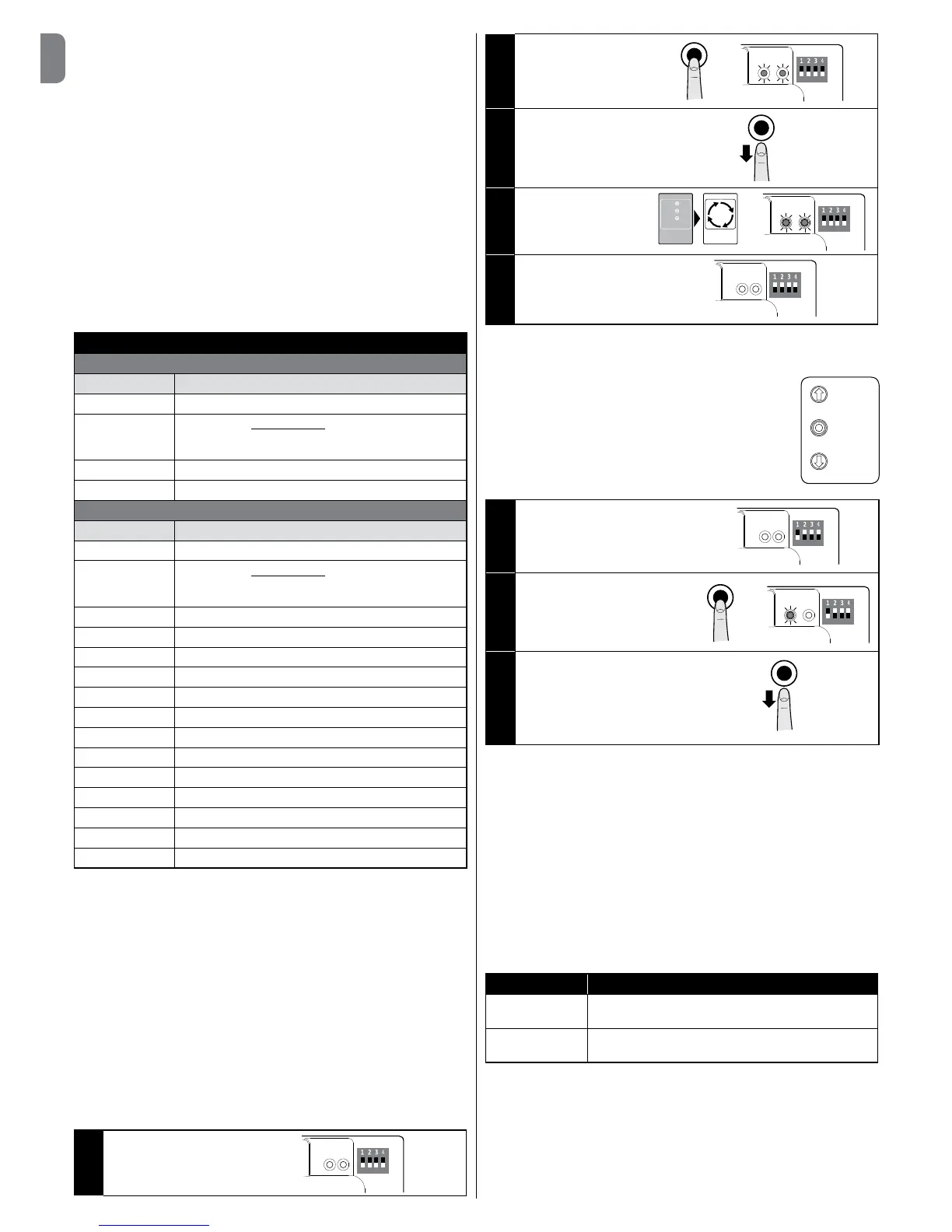

3.10 - Recognition of the safety devices and the Opening and

Closing positions

Afterperformingtheinitialstartup(paragraph3.8)andbe-

fore setting the gate Opening and Closing positions, you

must have the control unit run the recognition phase of

theconnectedsafetydevicesonthe“STOPSafetyEdge”

input.

CAUTION! - During the recognition phase, at least

one safety device must be connected to the control

unit.

OPEN

STOP

CLOSE

01. Setdipswitch1toON=

-GreenLEDbeginstoash

rapidly

-RedLEDisOFF

ON

OFF

02. Press and hold the STOP button

until the red led comes on and

remainslit(afterabout3sec.)

3”

ON

OFF

03. Release the STOP button

This procedure must be repeated if a modication is made to the

devices connected to the “STOP Safety Edge” terminal (for example,

after connecting a new device to the control unit).

After performing the recognition of the safety devices on the automated sys-

tem, the control unit must recognise the gate Opening and Closing positions.

CAUTION! - The recognition procedure of the safety devices and the

gate Opening and Closing positions must be done consecutively,

without interruption. You can not perform the recognition of the safety

devices at one time and the recognition of the positions at another

time.

3.10.1 - Recognition of the Opening and Closing positions with

mechanical limit switch

Youcanprogram2positions,asfollows:

Position Meaning

Opening Maximumopeningposition.Whenthegatereaches

this position it stops.

Closing Maximumclosingposition.Whenthegatereachesthis

position it stops.

Caution! - If the direction of rotation does not correspond to the direc-

tion set (Open button = opening direction), you need to invert the “V”

and “W” connections (phase inversion) in the motor connector (g. 9).

Loading...

Loading...