This“indicator”functionsinthefollowingway:

- off when the safety chain is open (ALT inp, red STOP button, thermal protec-

tion or release)

- ashes0.5sON,0.5sOFFwhenitworksproperly

- shows the same diagnostics as the red L1 WARNING LED when there are

“seriouserrors”(Paragraph6.2).

Setting the pause time for automatic closing

1 SetDIPswitches3and4toON.

2 Send a command to open the gate so as to move the gate to its fully open

position.

3 Once this position is reached, wait for a period of time equal to the required

pause time for automatic closing and then command the gate to close. The

pause time for automatic closing is now saved.

Inordertochangethepausetime,setdip3and4toOFFandthenbacktoON.

At this point you must repeat the sequence of opening, pause time and closing.

CAUTION! - WhenDIPswitch4ismovedtotheOFFposition,thepausetime

is deleted.

6.2 - Diagnostics

Some devices are equipped to display messages to identify their status and faults. The following table describes the various alarm signals according to the type

ofproblem.ThesealarmsignalsareprovidedbyappropriateashesofthegreenOKL2LEDandtheredWARNINGL1LEDandfromtheashinglight(ifthere

is one) connected to the specially programmed control unit outputs.

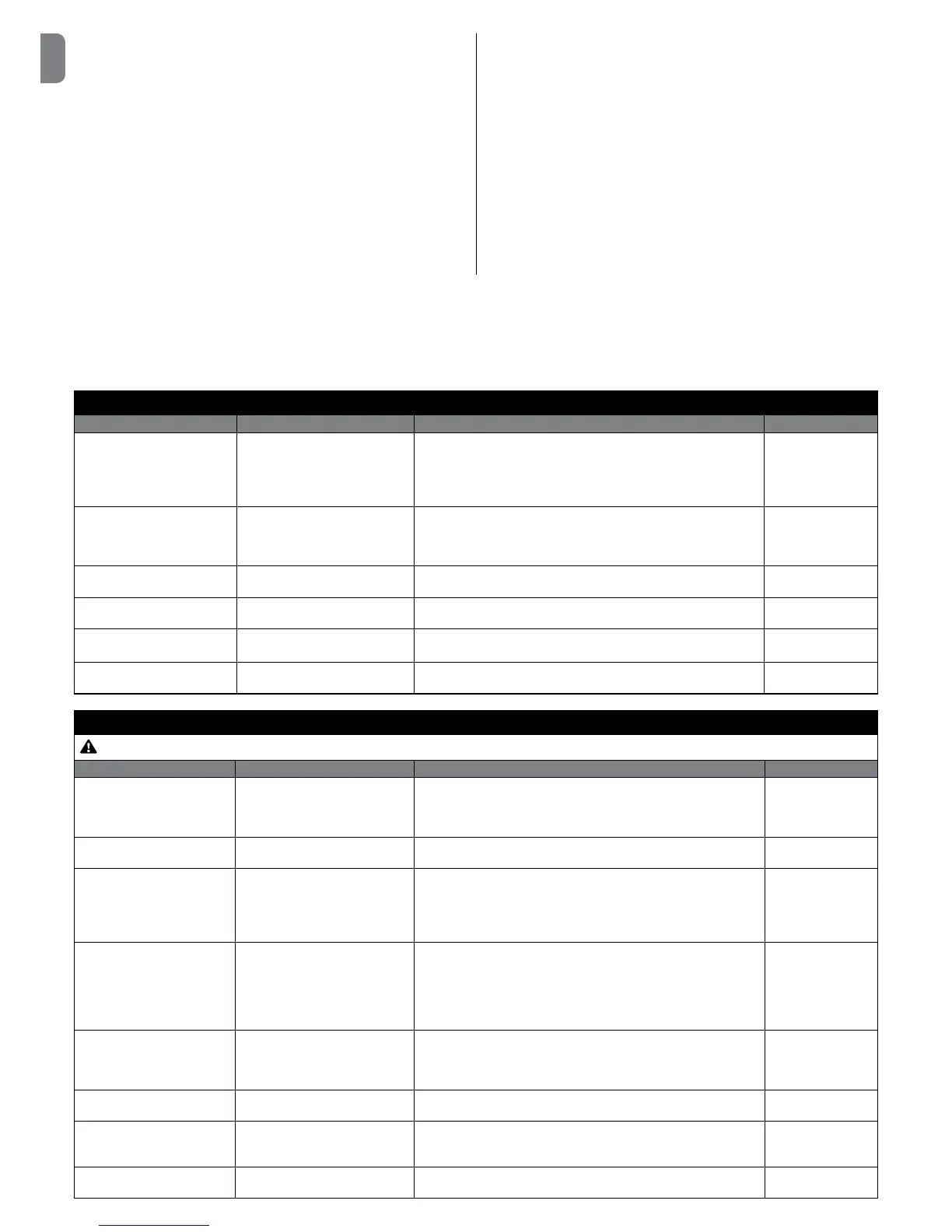

DIAGNOSTICS GREEN OK L2 LED

Signal Cause Solution Flashing light

2ashes-shortpause

2ashes-longpause

Triggering of a photocell

At the start of the manoeuvre, one or more photocells fail to give the

enable signal; check for obstacles and whether the photocells are in-

terfering with each other’s IR. When the safety devices have intervened,

the automation can be controlled with a person present through the

wired controls. It is not possible to send commands via radio.

Flash

4ashes-shortpause

4ashes-longpause

Triggering of the STOP input

At the start of or during the manoeuvre, the STOP or ALT input was

triggered; identify the cause. When the safety devices have intervened,

the automation can be controlled with a person present through the

wired controls. It is not possible to send commands via radio.

Flash

6ashes-shortpause

6ashes-longpause

Manoeuvre limiting device --- Flash

9ashes-shortpause

9ashes-longpause

Automation system locked Sendthe“ReleaseAutomation”commandorcommandthe

manoeuvrewith“Step-by-StepHighPriority”.

Flash

TheLEDscomeonfor3

seconds

Lock automation --- Flash

2ashesof1secondwith

pause of 1.5 seconds

Automation system released --- Flash

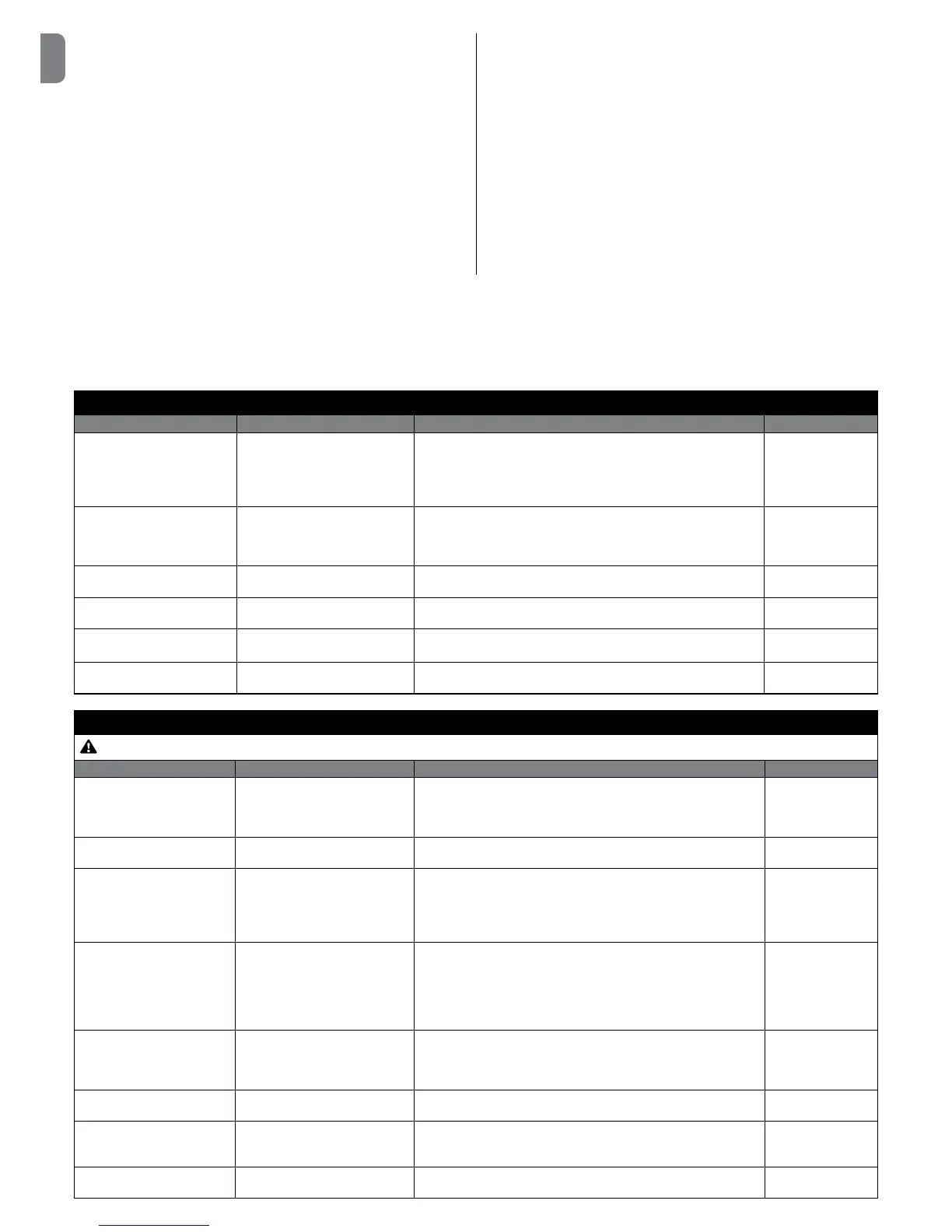

DIAGNOSTICS RED WARNING L1 LED

Certain signals can be cancelled by pressing the red STOP button

Signal Cause Solution Flashing light

5ashes-shortpause

5ashes-longpause

EEPROM error - Error in the

internal parameters of the control

unit

Disconnect and reconnect the power supply. If the error persists, run

the“Totaldeletionofthecontrolunitmemory”(paragraph3.8)and

rerun installation. If the condition persists, there may be a serious

fault and you will need to replace the electronic circuit board.

Flash

2ashes-shortpause

2ashes-longpause

Safety Test Error Rerun the recognition procedure for the safety devices connected to

thecontrolunit(paragraph3.9).

---

3ashes-shortpause

3ashes-longpause

Error in direction of rotation

of the Encoder Or inverted limit

switch

Reverse the direction of rotation of the encoder by moving DIP switch

2toON(seeparagraph3.10).Ifthemotormountsamechanicallimit

switch, reset the error by pressing the STOP button and invert the

opening limit switch connection with that of the closing limit switch

at the LIMIT SWITCH terminal (Fig. A - page 4).

4ashes-shortpause

4ashes-longpause

Error with safety limit switches The gate has gone past the safety limit switches during Opening

or Closing. Move the gate manually to about half way up using the

emergency manoeuvre system (see the manual of the motor) and

press the STOP button on the cover in order to restore operation.

Assess whether you need to change the previously acquired Open-

ing/Closingpositions.

---

6ashes-shortpause

6ashes-longpause

Error with contactor Disconnect all the power lines for a few seconds, then try sending a

command again; if the problem persists, there may be a serious fault

on the circuit board or on the connections of the motor. Carry out

checks and replace parts, if required.

---

7ashes-shortpause

7ashes-longpause

RS485communicationerroron

Encoder

Check that the motor-control unit cable is connected correctly, in

particulartheencodercable(6colouredwires).

---

8ashes-shortpause

8ashes-longpause

Encoder error Check that the motor-control unit cable is connected correctly, in

particulartheencodercable(6colouredwires).Reruntherecogni-

tion procedure of the Opening and Closing positions.

---

9ashes-shortpause

9ashes-longpause

Error in limit switch acquisition Repeat the recognition procedure of the Opening and Closing posi-

tions.

---

Loading...

Loading...