Control Methods Using an External Device

FQ2-S/CH User’s Manual

for Communications Settings

21

1

Overview of Communication Specifications

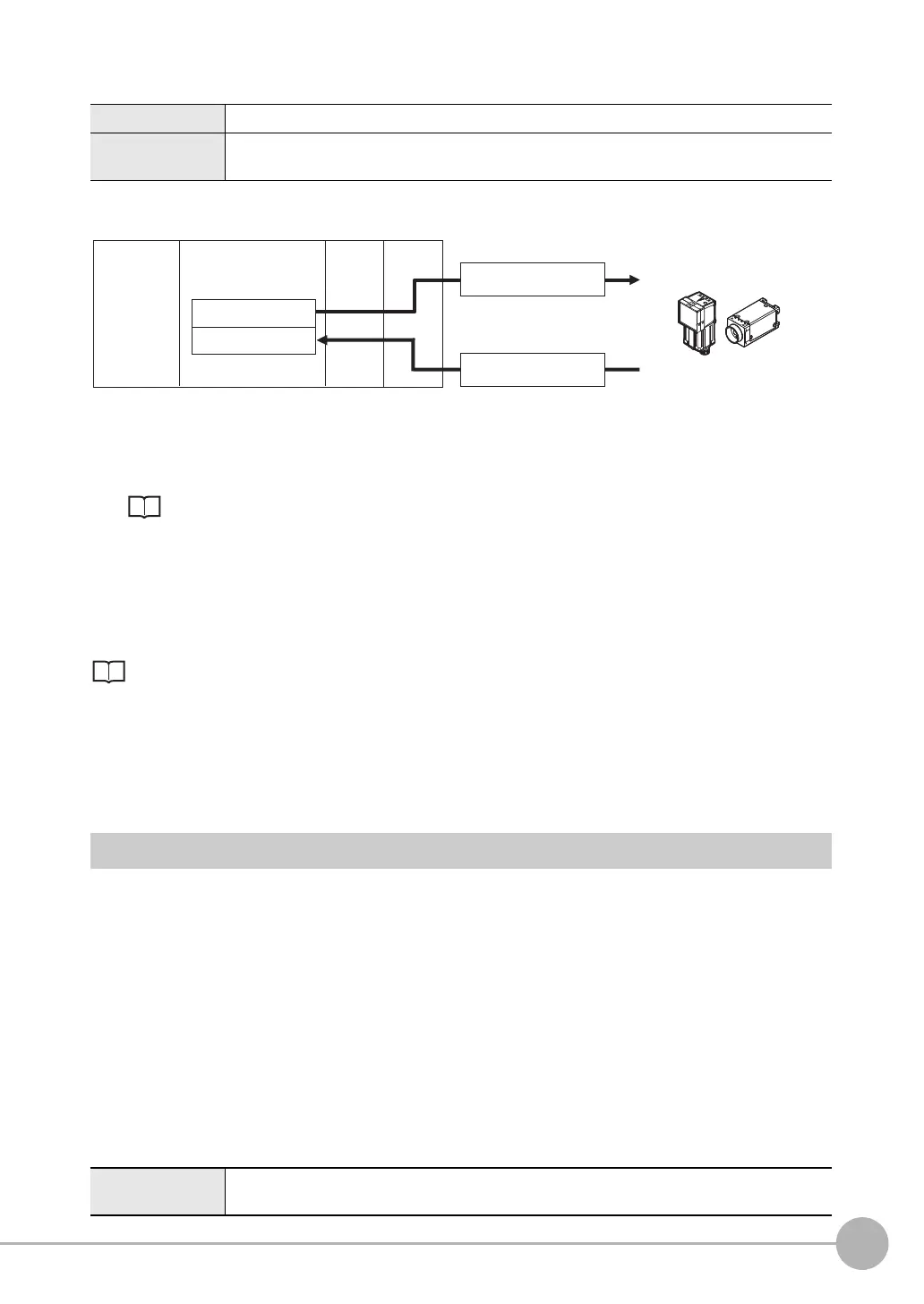

Memory Areas Used by the Command/Response Control Method

Flow of Communications between the PLC and the Sensor

(1) The PLC (the user) writes a control command to a specified PLC I/O memory area (the Command Area).

Parameter Notation Examples for Command Control: p.200

(2) The PLC (the user) then turns ON the EXE bit to send the control command to the Sensor.

(3) The Sensor executes the received control command.

(4) The Sensor returns a response to the PLC after the control command is executed.

(5) The PLC (the user) stores the response in a specified PLC I/O memory area (the Response Area).

The available control commands depend on the communications protocol that is used.

Command List: p.202.

No-protocol (TCP) Communications, No-protocol (UDP) Communications, No-protocol (FINS/

TCP) Communications

Communications commands are sent to the Sensor through sequence control in the PLC. An external device

and the Sensor communicate through no-protocol communications.

Data Output after Measurements

After a Single Measurement or Start Continuous Measurements command is executed, the Sensor

automatically outputs the data that corresponds to the measurements that have been specified as output items

to the PLC. This allows you to easily pass measurement results data from the inspection items to the PLC. You

can also choose to output only when the PLC meets the conditions that are required to receive the data (i.e.,

when handshaking is turned ON).

The output destination for data depends on the protocol that is used to communicate between the external

device and the Sensor, as described below.

PLC Link, EtherNet/IP, or PROFINET

The output data is automatically output to the following area that is specified PLC I/O memory.

Area of Memory Used for Data Output after Measurement

Command Area You write the control commands to execute for the Sensor to this area.

Response Area You read the results of executing the control commands that were written to the Command Area

from this area.

Data Output Area The output data for the measurement is written to this area by the Sensor after execution of the

measurement.

(1) Command Area

(5) Response Area

(2) Command

(4) Response

PLC

CPU Unit

I/O memory

(communications areas)

• Switch Scene Number

• Single Measurement, etc.

OK, etc.

(3) Command is processed.

Sensor

FQ2-S_CH_comm.book 21 ページ 2014年6月26日 木曜日 午前11時47分

Loading...

Loading...