4-2

INITIAL SETTING

CHAPTER 4 INITIAL SETTING

The "input type", "scaling

factor", and "decimal point

position" should be set in this

order.

Otherwise, auto-initialization

of parameters may result in a

failure in parameter setting.

If you specify the scaling

factor and then the input type,

the scaling factor is initialized

automatically.

4-1 K3MA-J (Process meter)

The following example shows the flow of initial setting for K3MA-J.

Flow of Initial Setting

A. Check wiring for correct connection and power the product on.

The product is factory set to have an analog input range of 4 to 20 mA.

If an input that falls outside this range is received, the main indicator of the

product will read "s.err" and blink, indicating an "input range over" error

occurs. This is not a trouble of the product.

B. Set "input type" to "±10 V".

1. Make sure the main indicator displays the current process value (the prod-

uct is at the operation level). Then press the L key for at least 3 seconds.

The product will move to the initial setting level.

2. Set parameter "in-t" to "10".

C. Specify the scaling factor.

1. Set parameter "inp.1" to "0.00".

2. Set parameter "dsp.1" to "0".

3. Set parameter "inp.2" to "10.00".

4. Set parameter "dsp.2" to "5000".

D. Specify the decimal point position.

1. Set parameter "dp" to "\\\\.\".

E. Set "OUT1 value type" to "upper limit" and "OUT2 value type" to "lower limit".

1. Set parameter "out1.t" to "hi".

2. Set parameter "out2.t" to "lo".

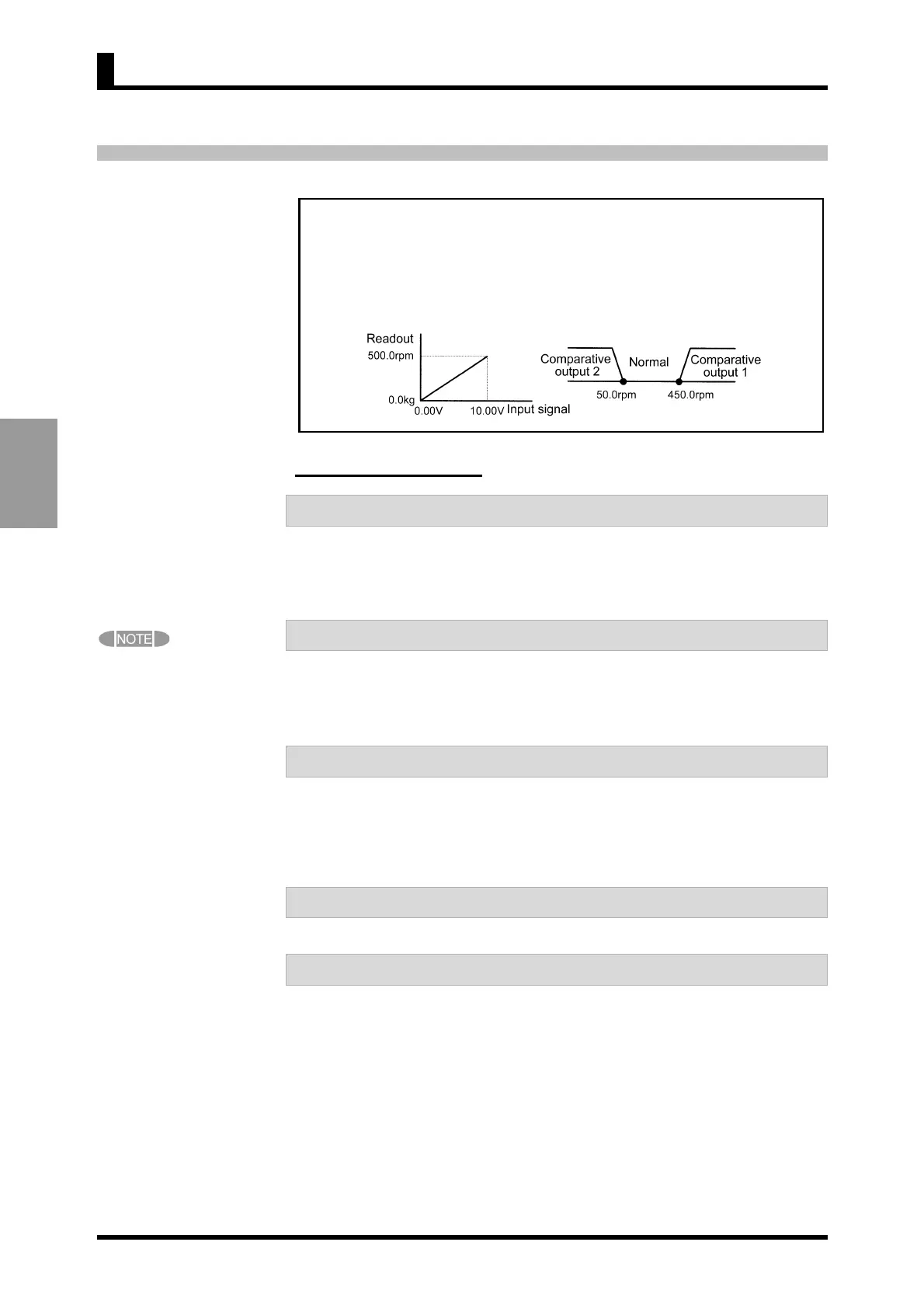

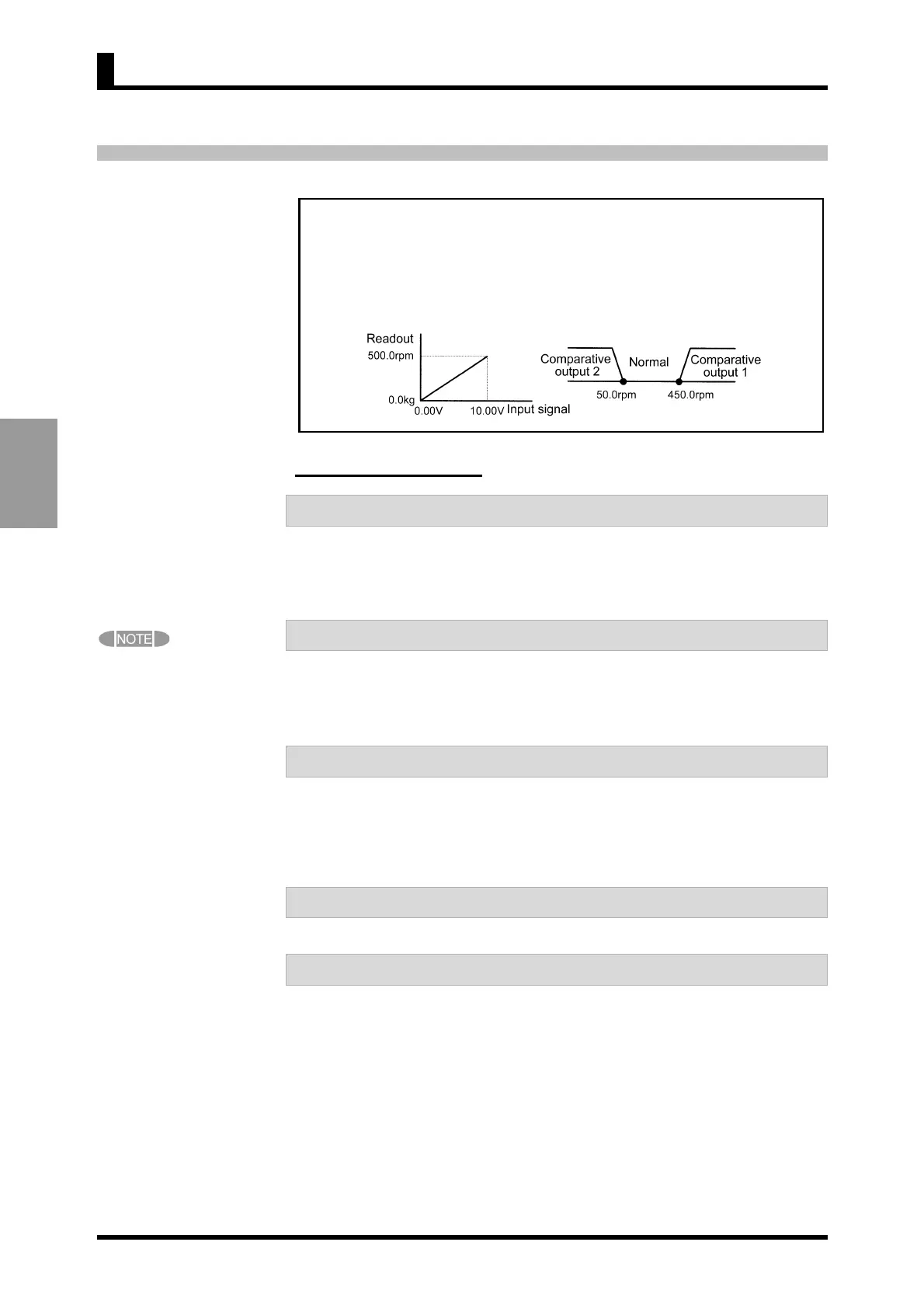

<Setting example>

Input signals ranging from 0 to 10 V is scaled to readouts ranging from 0 to

500.0 rpm.

When the process value (readout) reaches 450.0 rpm, comparative output 1 is

produced.

When the process value (readout) decreases to 50.0 rpm, comparative output 2

is produced.

Loading...

Loading...