5-5

5-4 Process Data Objects (PDOs)

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

5

EtherCAT Communications

5-4 Process Data Objects (PDOs)

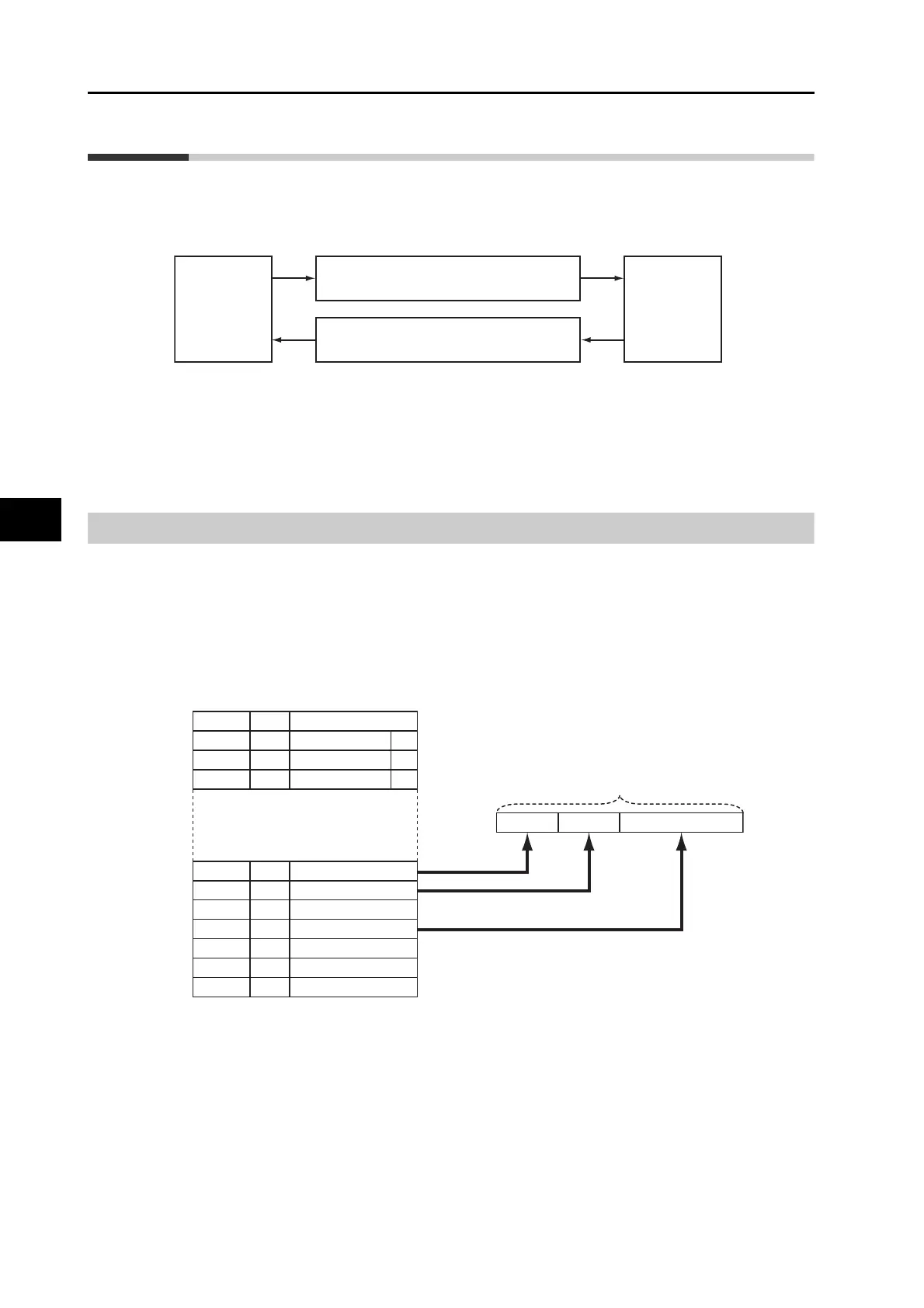

The process data objects (PDOs) are used to transfer data during cyclic communications in

realtime. PDOs can be reception PDOs (RxPDOs), which receive data from the controller, or

transmission PDOs (TxPDOs), which send status from the Servo Drive to the host controller.

The EtherCAT application layer can hold multiple objects to enable transferring Servo Drive

process data. The contents of the process data are described in the PDO Mapping object and

the Sync manager PDO assignment object.

OMNUC G5-series Servo Drives support PDO mapping for position control.

PDO Mapping Settings

The PDO mapping indicates the mapping for application objects (realtime process data)

between the object dictionary and PDO. The number of mapped objects is described in sub-

index 0 of the mapping table. In this mapping table, 1600 hex to 17FF hex are for RxPDOs and

1A00 hex to 1BFF hex are for TxPDOs.

G5-series Servo Drives use 1701 hex for RxPDOs and 1B01 hex for the TxPDOs.

The following table is an example of PDO mapping.

Host

Controller

Servo Drive

RxPDO

Operation command, target position, etc.

TxPDO

Operation status, actual position, etc

6TTTh

ZZh

Index

Sub

6UUUh UUh

16

Object contents

1ZZZh

1ZZZh

1ZZZh

01h

02h

03h

6TTTh TTh

YYYYh YYh

8

8

6UUUh

6VVVh

6YYYh

UUh

VVh

YYh

TTh Object A

Object B

6ZZZh

Object C

Object D

Object E

Application objects Mapping objects

Object Dictionary

Object A Object B Object D

PDO_1

PDO-Length: 32 bits