11-27

11-9 Friction Torque Compensation Function

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

11

Adjustment Functions

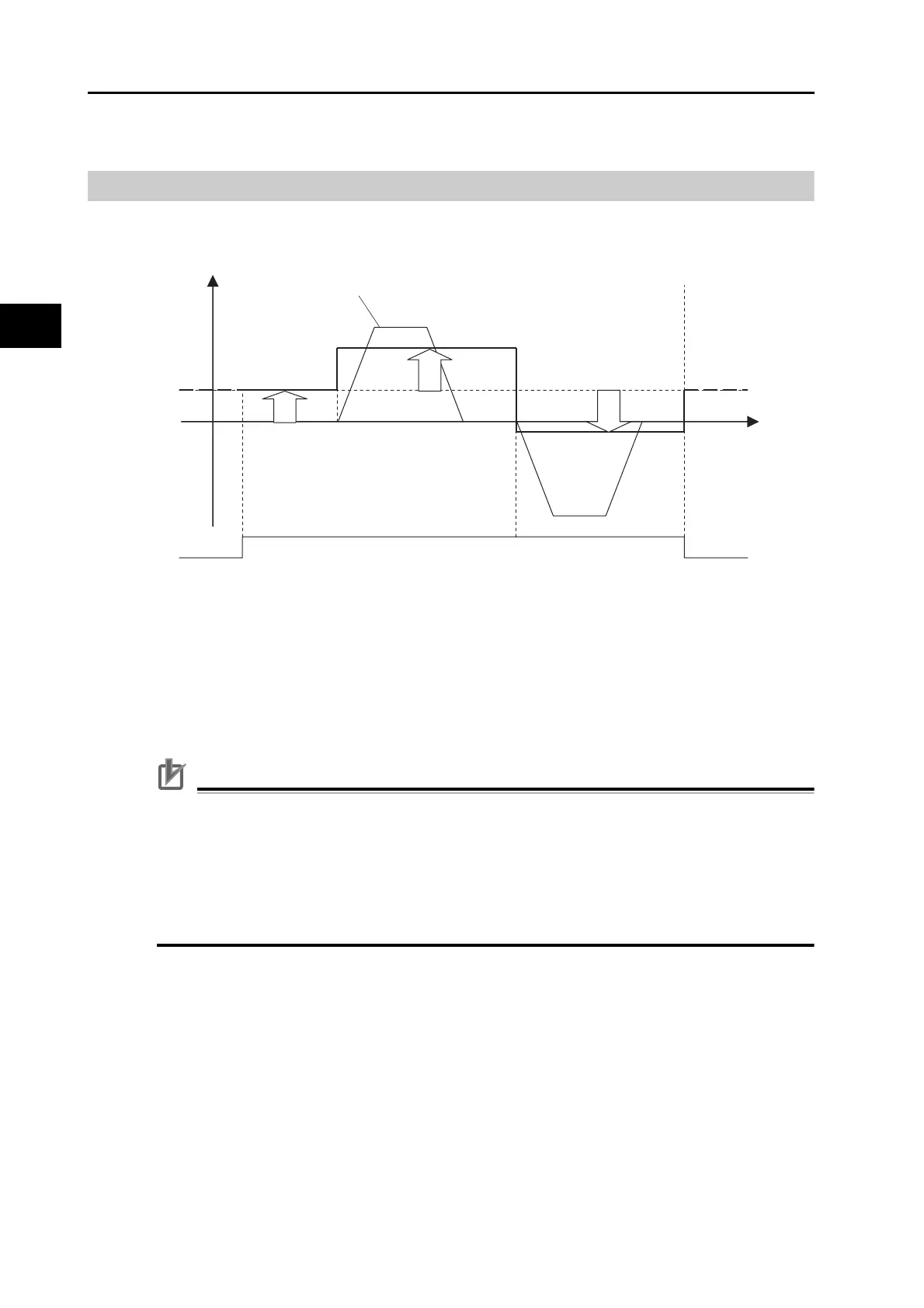

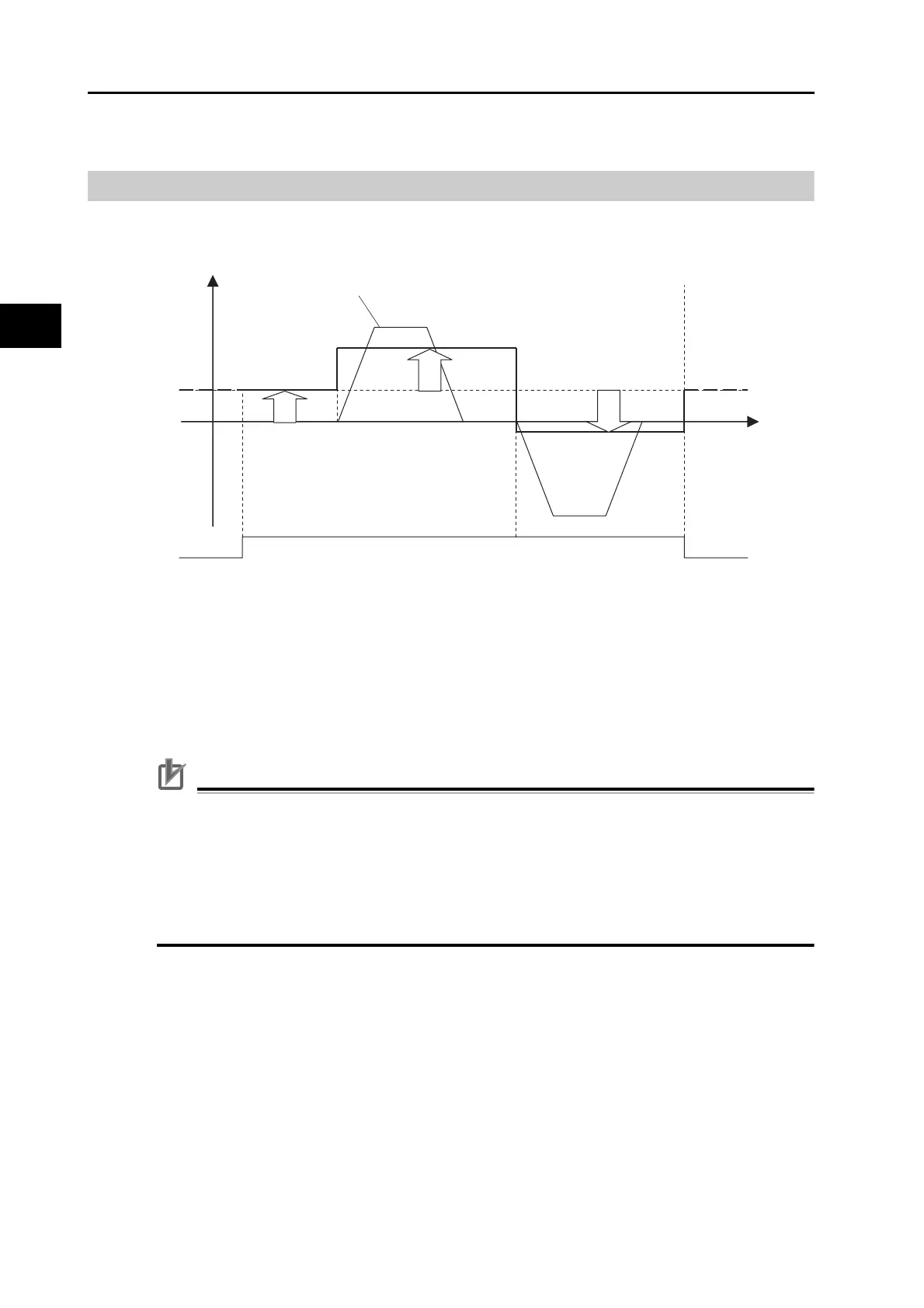

Operation Example

The friction torque compensation is applied in the input direction of the position command as

shown in the drawing below.

The Torque Command Value Offset (3607 hex) reduces the variations of positioning

operations due to the movement directions when a certain amount of unbalanced load torque

is always applied to the motor at the vertical axis by setting the torque command.

By setting the friction torque for each rotation direction in the Forward Direction Torque Offset

(3608 hex) and Reverse Direction Torque Offset (3609 hex), you can reduce the deterioration

of and inconsistencies in the positioning stabilization time due to dynamic friction for loads that

require a large amount of dynamic friction torque due to a radial load, such as the belt-driven

shaft.

Precautions for Correct Use

You can use unbalanced load compensation and the dynamic friction compensation together

or separately. The following application limit applies.

Servo ON

The unbalanced load compensation and the dynamic friction compensation values are held until

the first position command is input. When the position command is input, the unbalanced load

compensation is updated based on 3607 hex. Also, based on the command direction, the dynamic

friction compensation value is updated according to objects 3608 and 3609 hex.

Command speed

Time

Motor

de-energized

Motor

de-energized

Motor power supply

3607 hex

(Torque command

value offset)

Forward

Reverse

3608 hex (Forward Direction

Torque Offset)

3609 hex

(Reverse Direction

Torque Offset)

Loading...

Loading...