22

FA ROTEX GW - 09/2012

5 x Start-up

5 Start-up

Incorrect start-up makes the manufacturer's guarantee for the

unit void. If you have questions, please contact our Technical

Customer Service.

5.1 Initial start-up

Once the ROTEX GW is installed and fully connected, it can be

put into operation by expert technicians.

5.1.1 Requirements

– The ROTEX GW is fully connected.

– Optional accessories have been mounted and connected up.

– The control valves of the heating system are open.

– The gas supply to the ROTEX GW is open.

5.1.2 Filling the condensate siphon

5.1.3 Checks before initial start-up

Ɣ Check all connections for leakage.

Ɣ Check all the points on the checklist (see chapter 5.1.7). Log

the test results on the checklist.

Ɣ Only if all points on the checklist can be answered with Yes

may the ROTEX GW be started up.

5.1.4 Filling the system and bleeding

After completing the installation, fill and bleed the ROTEX GW in

the following sequence:

1. Switch the ROTEX GW to the "standby mode"

(see chapter 6.4.3 "Operating mode Standby").

2. Fill the hot water circuit.

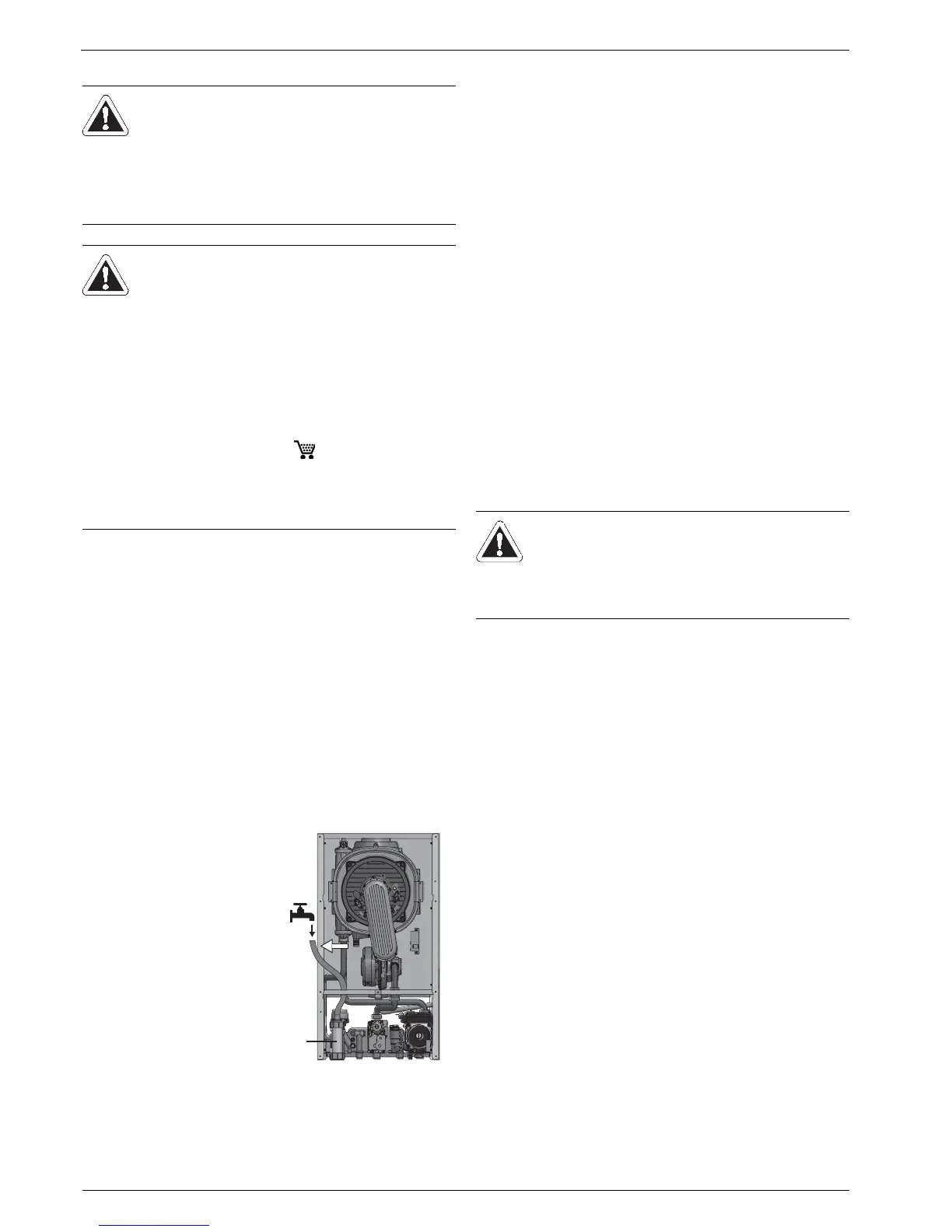

Ɣ Open the isolating valve on the cold water supply

(fig. 5-2, item 1).

Ɣ Open the draw-off points for the hot water.

Î To make sure that the plate heat exchanger in the ROTEX

GW is fully bled, and any contaminants or residues are

flushed out, the cold water supply should not be turned off

immediately after water comes out of the draw-off loca-

tions.

Ɣ Close all the draw-off locations after adequate bleeding.

3. Filling the heating circuit.

Ɣ Open all the regulating valves on the system.

Ɣ Connect the filling hose with return flow inhibitor (1/2") at

the filling and draining fittings (KFE cock, fig. 5-2, item 3)

and secure against slipping off by using a hose clamp.

Ɣ Open the water cock (2) in the filling hose supply line.

Ɣ Open KFE cock (fig. 5-2, item 3) slowly.

Ɣ Check the automatic bleed on the heating circulation

pump (fig. 3-3, item 22) to make sure that it is open during

the filling process, open by hand if necessary.

Ɣ Fill the system and heating circuit with water until a water

pressure of 1.5 bar to 2.5 bar is indicated on the display

on the controller.

Ɣ Close KFE cock (fig. 5-2, item 3).

Ɣ Bleed the entire heating circuit.

Ɣ Bleed the boiler heat exchanger using the manual bleeder

(fig. 5-2, item 4).

Ɣ Check the water pressure on the controller again and top

up with water if necessary.

Ɣ Close the water cock (2) in the filling hose supply line.

Ɣ Remove the filling hose with flow-back preventer from the

KFE cock (fig. 5-2, item 3).

WARNING!

A heating system that is commissioned incorrectly

may not operate properly and is dangerous for the

health and the life of individuals.

Ɣ Start-up of the ROTEX GW may only be carried out

by heating technicians authorised and trained by

the gas or power supply company.

CAUTION!

A ROTEX GW which was put into operation incorrectly

can cause damage to property and the environment.

Ɣ Observe the regulations in VDI 2035 in order to

avoid corrosion and deposits.

Ɣ Measures for desalination, softening or hardness

stabilization are necessary, if the filling and top-up

water has a high total hardness (>3 mmol/l - sum

of the calcium and magnesium concentrations,

calculated as calcium carbonate).

Ɣ We recommend Fernox scale and corrosion

protection agent KSK ( 15 60 50).

Ɣ When the system ids operating, the water pressure

at the controller (1.5 bar - 2.5 bar) must be

checked at regular intervals. If necessary, readjust

by topping up.

Ɣ Remove the condensate

drain hose from the burner

housing.

Ɣ Pour 0.2 litres of tap water

into the condensate

siphon (1).

Ɣ Refit the condensate drain

hose onto the burner

housing.

Alternatively, the water can be

added without having to

remove the condensate drain

hose through the inspection

opening in the exhaust.

Fig. 5-1 Filling the condensate

siphon

Loading...

Loading...