34

FA ROTEX GW - 09/2012

7 x Gas burner

7.3 Burner setting

The gas burner on the ROTEX GW is set to the gas type natural

gas E/H (G20 - 20 mbar) in the factory. If the unit is to be operated

with natural gas LL/L or liquid gas, it must first be changed over

to this type of gas by fitting the appropriate insert in the gas valve

(included in the delivery, see tab. 7-3) and the burner setting

must be checked.

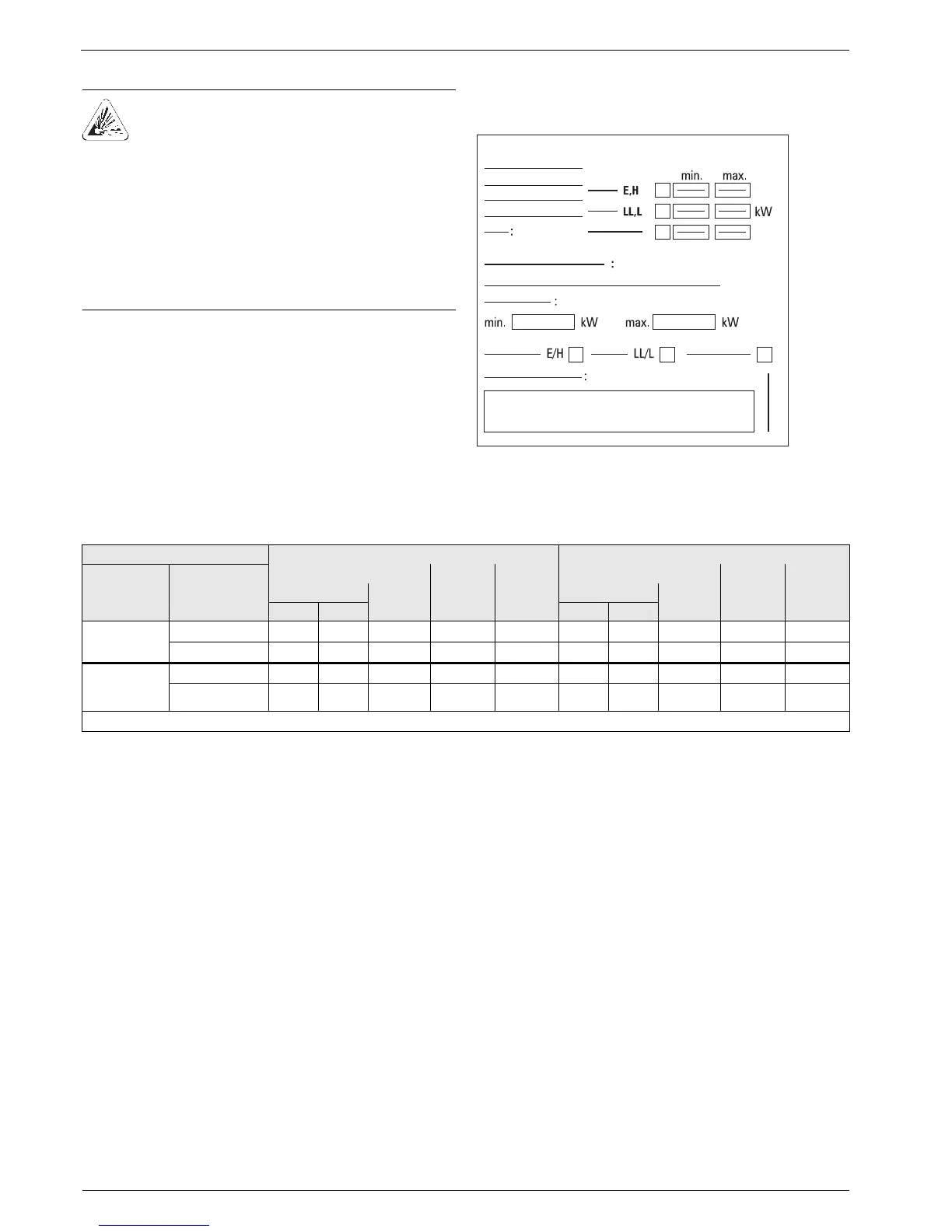

If changes to the performance settings of the burner or a

changeover to a new gas type must be made, these changes

must be documented in the operating manual and entered onto

the settings type plate (fig. 3-3, item 28).

The changeover must be provided with the date of implemen-

tation and the signature of the installer.

7.3.1 Setting values

7.3.2 Checking and setting the burner

The gas burner has been factory-set for a certain gas type. The

preset gas type and the designated gas inlet pressure are

indicated on the type identification plate under the sound

deadening hood.

Checking the burner output with the special function "emission

measurement" and using a flue gas analyser

– at maximum (full) load = 100 %,

– at minimum (base) load = 0 %.

If the emission measurement is activated (see chapter 6.7.1) the

boiler can be operated manually between full load and base load.

These settings can be individually adapted within the permitted

limits (see tab. 7-1) to the system requirements.

Auxiliary resources

– Flue gas analysis device.

– Pressure meter for measuring gas pressure.

Checking and setting (observe the sequence)

1. Inspect the pre-settings, so that the burner is set to the correct

gas type and the correct gas inlet pressure.

If the test gas indication on the type identification plate varies

from the test gas associated to the available gas type or if the

stated value deviates from the permissible gas inlet pressure,

the burner must be converted to the local conditions (see

chapter 7.3.3 to 7.3.6).

2. Turn the screw in the gas inlet pressure measuring

connection (fig. 7-1, item 9) anticlockwise by half a turn and

push up the measuring hose of the pressure meter.

3. Open the gas isolating valve.

4. Measure the gas inlet pressure (idle pressure) and compare

it with the target value (according to tab. 12-4). Leave the

measuring instrument connected.

Î If the gas inlet pressure (resting pressure) is outside the

set value range: Inform your gas supply company or

check the pressure regulator (for liquid gas).

5. Open the heating valves.

DANGER OF EXPLOSION!

Escaping gas is a direct threat to human health and

safety. Even a few sparks can cause major explo-

sions.

Ɣ Always close the gas stopcock of the house before

working on gas-conducting parts.

Ɣ If you can smell gas, air the room thoroughly. Do

not kindle any open fire or operate any electrical

switches.

Ɣ Only heating specialists authorised and trained by

the gas or power supply company should be

allowed to work on gas-conducting parts.

Fig. 7-2 Settings type plate

ROTEX GW type GW 22C GW 26C

Gas type

(Test gas)**

Setting for con-

trol -measure-

ment

Power setting CO

2

-con-

tent in %

(

±0.2%)

O

2

-content

in %

(

± 0.1%)

Power setting CO

2

-con-

tent in %

(

±0.2%)

O

2

-content

in %

(

± 0.1%)

Blower speed Load in

kW

Blower speed Load in

kW

in % in 1/min in % in 1/min

Natural gas E,H

LL, L (G20/G25)

Full load 100 5500 21.6 9.4 4.2 100 6100 26.2 9.6 3.8

Basic load 0 1500 4.5 9.0 4.9 0 1650 5.8 8.9 5.1

Liquid petrole-

um gas*

(G30/G31)

Full load 100 5300 21.6 10.9 4.3 100 6000 26.2 10.9 4.3

Basic load 0 1400 4.5 10.4 5.1 0 1600 5.8 10.5 5.0

* For changeover to liquid petroleum ** Compare details on type identification plate ROTEX Factory settings

Tab. 7-1 Flue setting values and speed limits for ROTEX GW for various different gas types

Loading...

Loading...