Immediately perform an inspection after such faults.

9.2.2 Initial inspection

Perform the following checks after approximately 500 operating hours or at the latest after six

months:

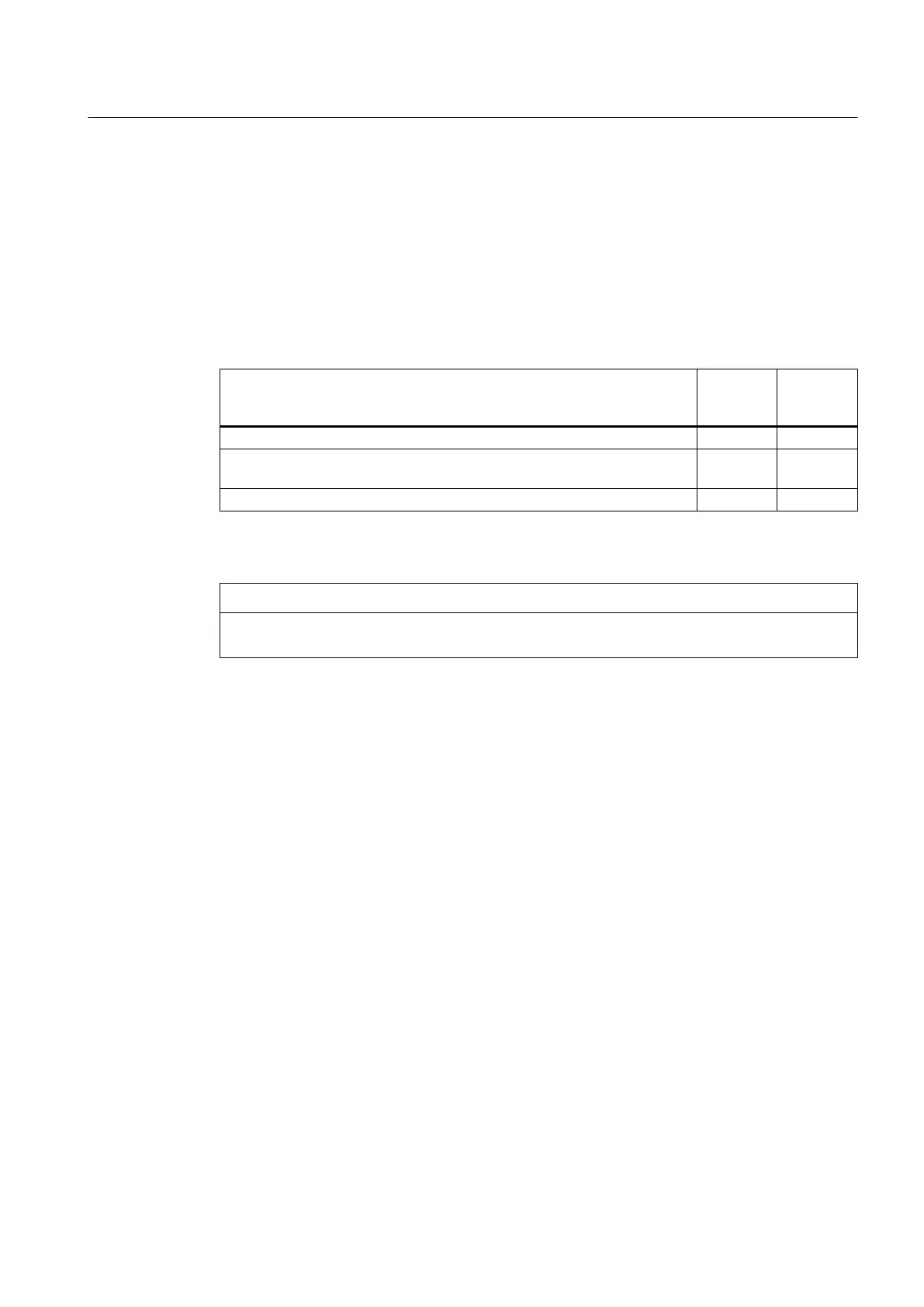

Table 9-1 Checks after installation or repair

Check When the

motor is

running

At stand‐

still

The electrical parameters are maintained. X

The smooth running characteristics and machine running noise have not

deteriorated.

X

The motor foundation has no cracks and indentations. (*) X X

(*) You can perform these checks while the motor is running or at a standstill.

Additional checks may also be required according to the system-specific conditions.

NOTICE

If you detect any deviations during the inspection, you must rectify them immediately. They

may otherwise damage the motor.

9.2.3 Main inspection

● While the motor is running, check that:

– The stated electrical characteristics are being observed

– The smooth running characteristics and machine running noise have not deteriorated

● Once the machine has been shut down, check that:

– The motor foundation has no indentations or cracks

– The machine is aligned within the permissible tolerance ranges

– All the fixing bolts/screws for the mechanical and electrical connections have been

securely tightened

– The winding insulation resistances are sufficiently high (Page 50)

– Any bearing insulation has been fitted as shown on plates and labeling.

– Cables and insulating parts and components are in good condition and there is no

evidence of discoloring

Maintenance

9.2 Inspection and maintenance

SIMOTICS M-1PH8 1PH818., 1PH822.

Operating Instructions 07/2016 103

Loading...

Loading...