Lubricating using the regreasing system

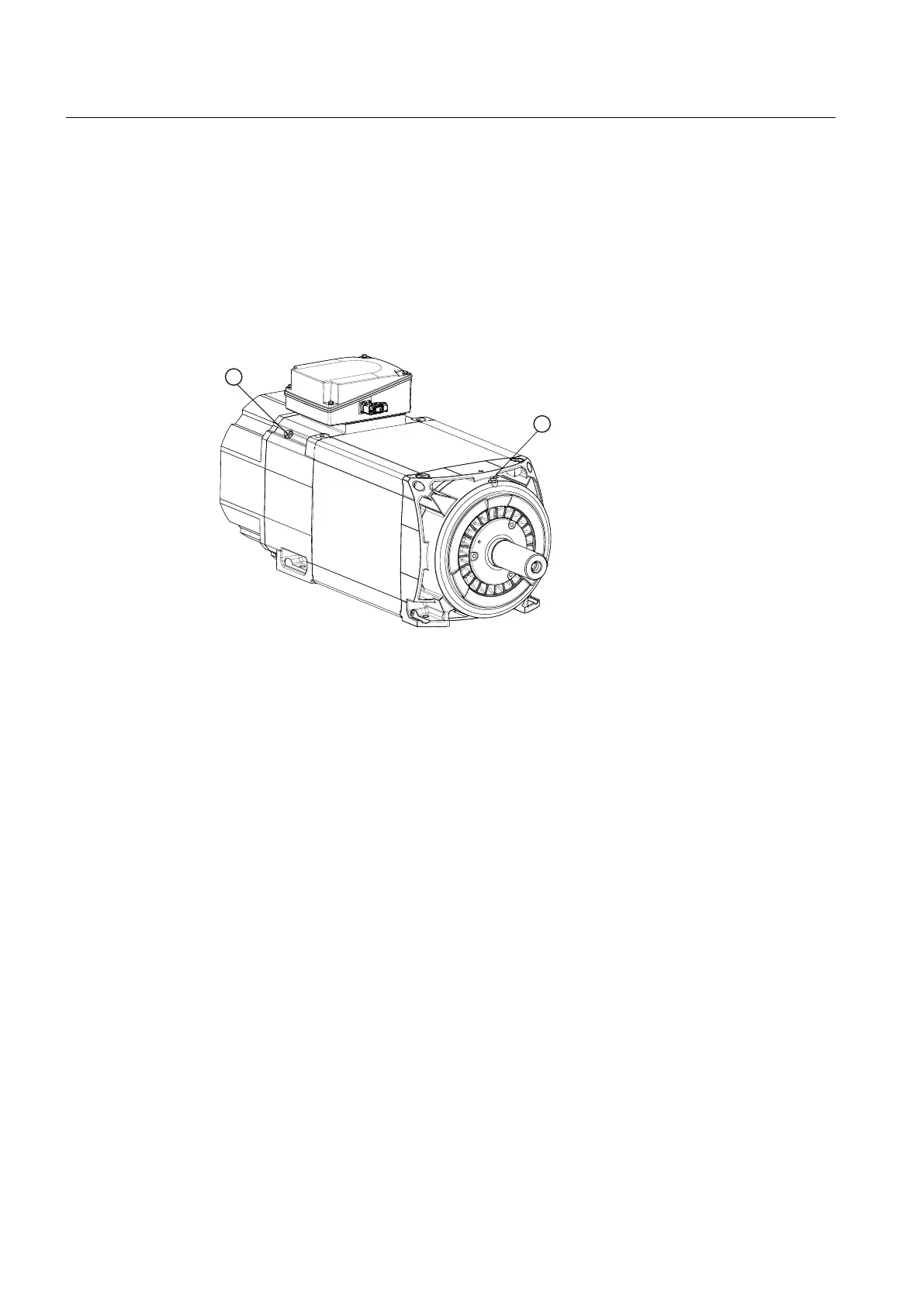

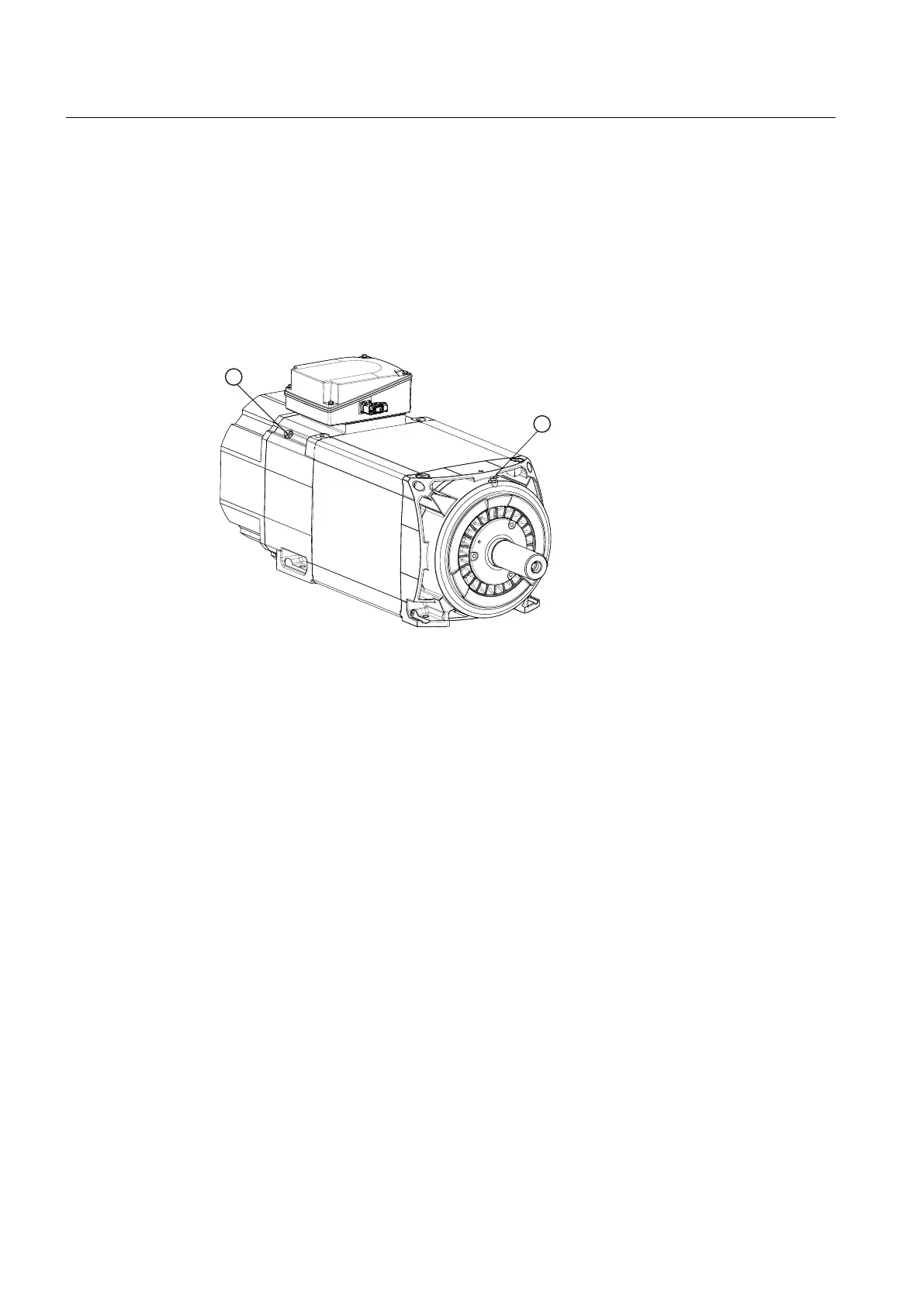

A flat grease nipple in accordance with DIN 3404, size M10x1, is provided at both the DE ①

and the NDE ② for regreasing.

1. Clean the grease nipples at the DE and NDE.

2. Press in the type and quantity of grease specified (see lubrication instruction plate). The

shaft rotates so that the new grease is evenly distributed throughout the bearing.

The bearing temperature initially increases noticeably. After the excess grease has been

displaced out of the bearing, the temperature will return to the normal value.

Figure 9-1 Flat grease nipples ① and ②, schematic representation for types 1PH818. and

1PH822.

9.2.6.5 Cleaning the spent grease chamber

The rolling-contact bearing's spent grease chamber only has room for a limited amount of

spent grease. When the spent grease chamber is full, the spent grease must be removed,

otherwise it will penetrate into the interior of the machine. The information on the amount of

grease to be used when regreasing can be found on the lubricant plate. When changing the

bearings remove the spent grease that has collected in the spent grease chamber and in the

outer bearing cover.

Maintenance

9.2 Inspection and maintenance

SIMOTICS M-1PH8 1PH818., 1PH822.

110 Operating Instructions 07/2016

Loading...

Loading...