The following information is provided regarding the state of the winding insulation:

● Is the winding head insulation conductively contaminated?

● Has the winding insulation absorbed moisture?

As such, you can determine whether the machine needs commissioning or any necessary

measures such as cleaning and/or drying the winding:

● Can the machine be put into operation?

● Must the windings be cleaned or dried?

Detailed information on testing and the limit values can be found here:

"Testing the insulation resistance and polarization index" (Page 50)

9.2.6.2 Maintenance intervals

Perform the following maintenance measures after the operating time or the intervals specified

in the following table elapse.

Table 9-2 Maintenance measures

Maintenance measures Maintenance intervals

Initial inspection After 500 operating hours, at the latest after six months

Regreasing See the lubricant plate

Permanent lubrication (with coupling

output)

Replace bearings after approximately 20,000 operating hours,

at the latest after three years

Cleaning Depending on the degree of pollution

Main inspection After approximately 16,000 operating hours, at the latest after

two years

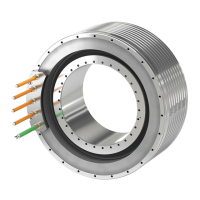

9.2.6.3 Rolling-contact bearings

The motors have rolling-contact bearing bushes for grease lubrication. Depending on the

version, the motors are permanently lubricated or are equipped with a regreasing device.

Depending on the type of load, a deep-groove ball bearing or a cylindrical-roller bearing is

fitted as a floating bearing on the drive end.

The DE bearing contains built-in compression springs that help to rebalance the axial play of

the external bearing rings.

See also

Description (Page 21)

9.2.6.4 Lubrication

The specified grease data apply for the data specified on the rating plate data and for high-

quality grease in accordance with the specifications in these operating instructions. These

Maintenance

9.2 Inspection and maintenance

SIMOTICS M-1PH8 1PH818., 1PH822.

Operating Instructions 07/2016 105

Loading...

Loading...