10-2 ELECTRICAL SYSTEM

CAUTIONS IN SERVICING

CONNECTORS

• When disconnecting a connector, be sure to hold the termi-

nals; do not pull the lead wires.

• When connecting a connector, push it in so it is firmly

attached.

• Inspect the connector for corrosion, contamination and any

breakage in the cover.

COUPLERS

• With a lock-type coupler, be sure to release the lock before

disconnecting it. When connecting a coupler, push it in until

the lock clicks shut.

• When disconnecting a coupler, be sure to hold the coupler; do

not pull the lead wires.

• Inspect each terminal on the coupler for looseness or bends.

• Inspect each terminal for corrosion and contamination.

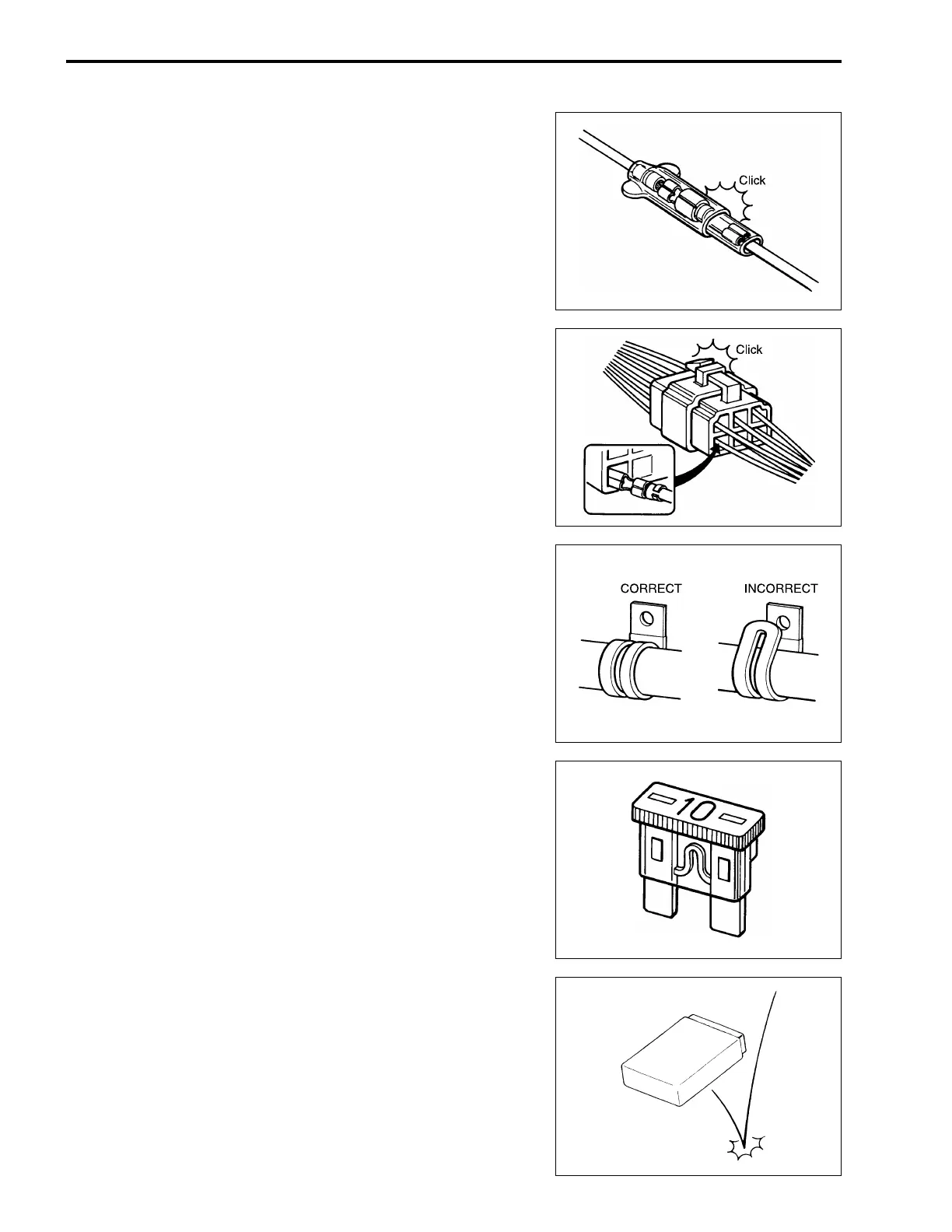

CLAMPS

• Refer to the “WIRING HARNESS ROUTING” section for

proper clamping procedures. (11-14 to 11-17)

• Bend the clamp properly, as shown in the illustration.

• When clamping the wire harness, do not allow it to hang

down.

• Do not use wire or any substitutes for the band-type clamp.

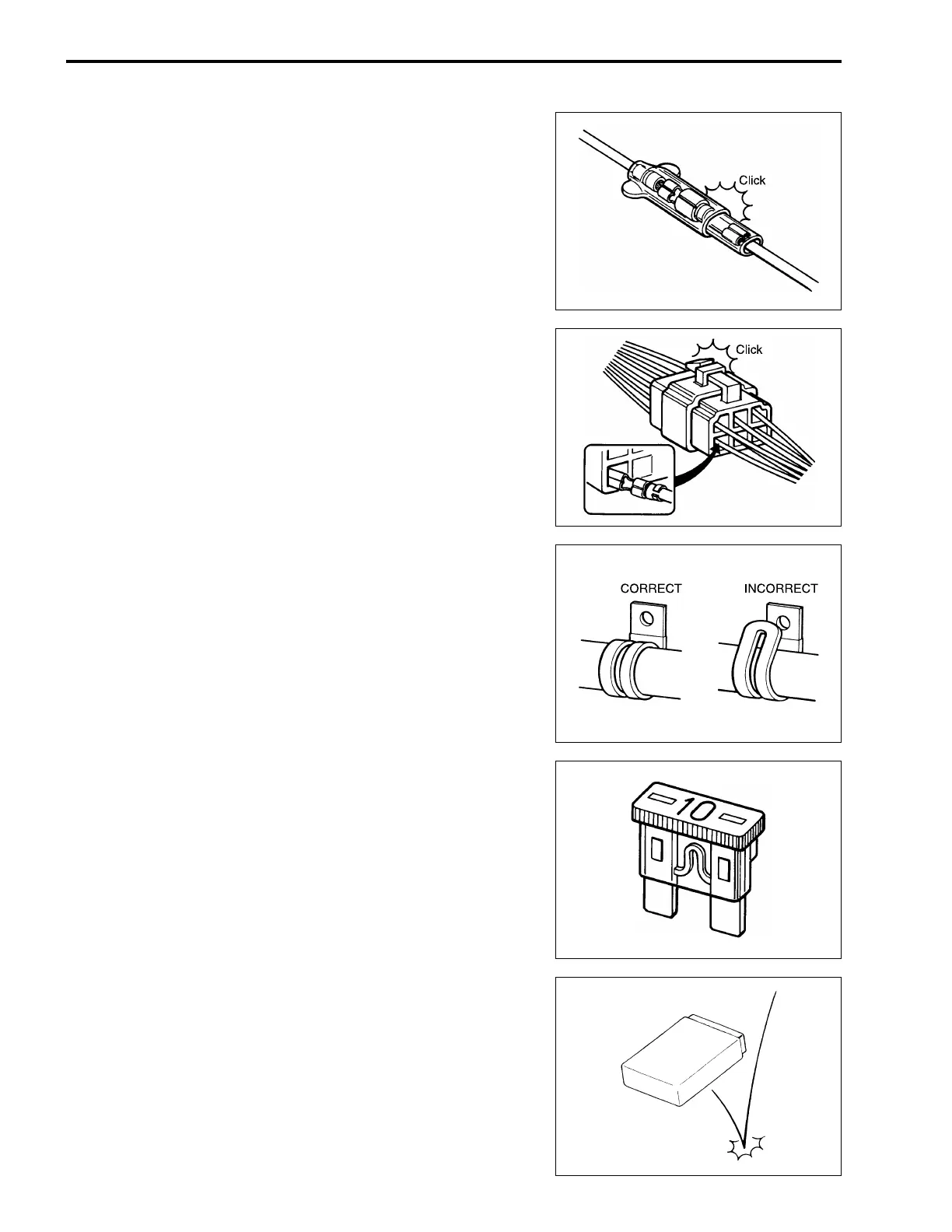

FUSES

• When a fuse blows, always investigate the cause, correct the

problem, and then replace the fuse.

• Do not use a fuse of a different capacity.

• Do not use any substitutes for the fuse (e.g., wire).

SEMI-CONDUCTOR EQUIPPED PARTS

• Do not drop any part that contains a semi-conductor (e.g.,

ECM, CVT control unit, regulator/rectifier).

• When inspecting the part, follow the inspection instructions

carefully. Neglecting proper procedures may cause this part

to be damaged.

INCORRECT

Loading...

Loading...