Blast chillers | User and maintenance manual | EN

27

DESCRIPTION OF THE BLAST CHILLER

The current manual refers to a blast chiller that is an appliance suited for cooling quickly cooked food

to a temperature of +3° C (positive process) or to -18° C (negative process).

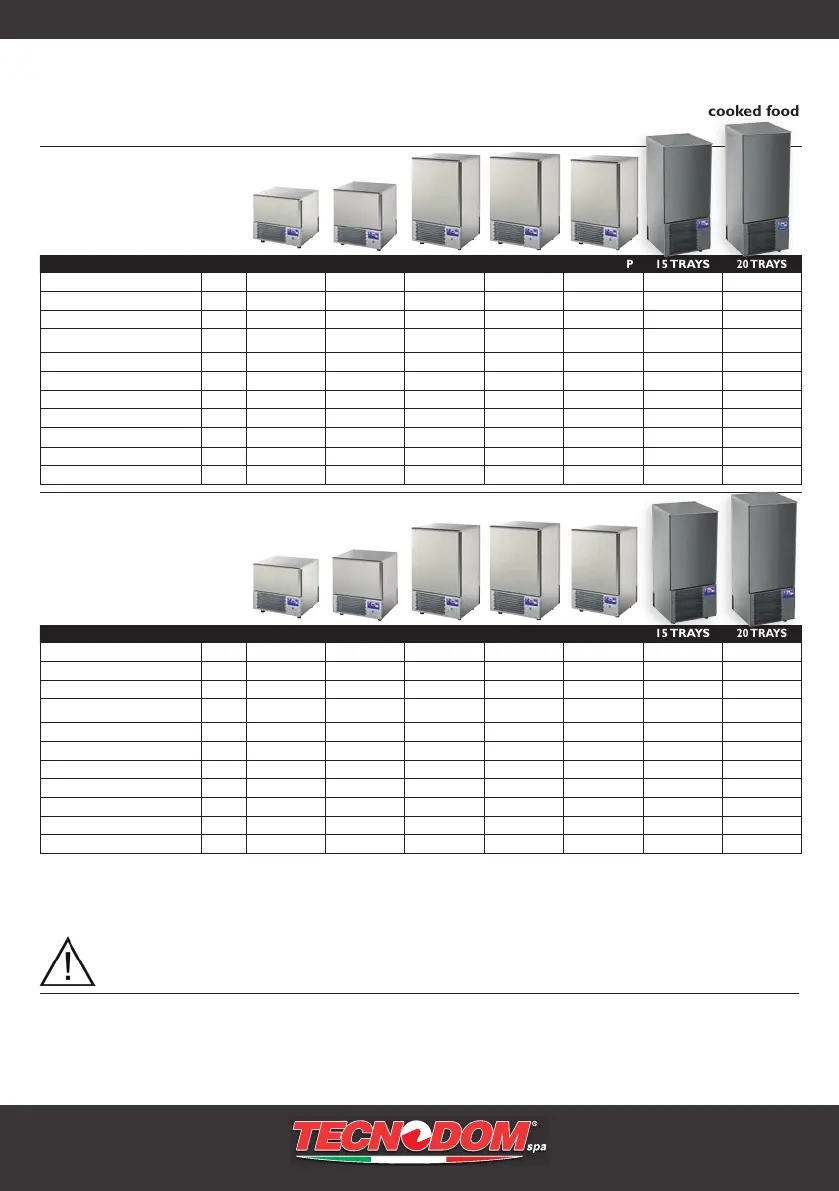

WITH

UNIT

3 TRAYS 5 TRAYS 7 TRAYS

10 TRAYS 10 TRAYS P

15 TRAYS

20 TRAYS

DIMENSIONS

WxDxH mm

750x750x770/790 750x750x890/910

750x750x1260/1280750x750x1260/1280750x750x1260/1280750x750x1850/1870750x750x2080/2100

NET WEIGHT

kg 82 92 111 112 117 166 184

CHAMBER DIMENSIONS

WxDxH mm

616x430x270 616x430x390 616x430xx760 616x430x760 616x430x760 616x430x1110 616x430x1340

CAPACITY TG

3 GN1/1

3 600x400

5 GN1/1

5 600x400

7 GN1/1

7 600x400

10 GN1/1

10 600x400

10 GN1/1

10 600x400

15 GN1/1

15 600x400

20 GN1/1

20 600x400

SPACE BETWEEN TRAYS cm 7 7 10,5 7 7 7 7

BLAST CHILLING PERFORMANCE

+3°C 15 kg 23 Kg 25 Kg 25 Kg 35 Kg 45 Kg 60 Kg

BLAST FREEZING PERFORMANCE

-18°C 9 kg 12 Kg 15 Kg 15 Kg 20 Kg 25 Kg 35 Kg

GAS GAS R452A/R507A R452A/R507A R452A/R507A R452A/R507A R452A/R507A R507 R507

TEST DETAIlS °C / RH +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65%

ABSORBED POWER W 40 50 65 65 65 70 85

POWER SUPPLY V-P-Hz 220/240-1-50 220/240-1-50 220/240-1-50 220/240-1-50 220/240-1-50

380V-3P-N-50Hz 380V-3P-N-50Hz

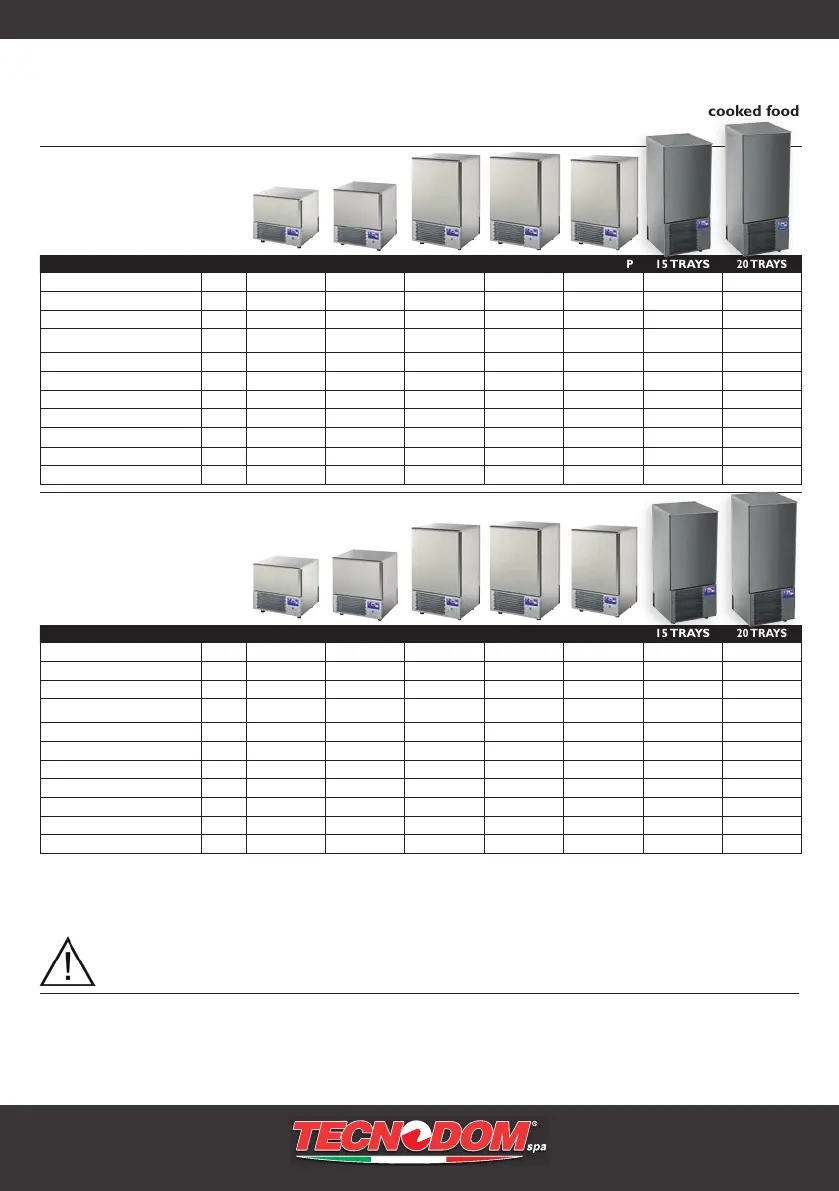

WITHOUT

UNIT

3 TRAYS 5 TRAYS 7 TRAYS

10 TRAYS 10 TRAYS P

15 TRAYS

20 TRAYS

DIMENSIONS

WxDxH mm

750x750x770/790 750x750x890/910

750x750x1260/1280 750x750x1260/1280 750x750x1260/1280 750x750x1850/1870 750x750x2080/2100

NET WEIGHT

kg 51 60 76 77 77 104 119

CHAMBER DIMENSIONS

WxDxH mm

616x430x270 616x430x390 616x430xx760 616x430x760 616x430x760 616x430x1110 616x430x1340

CAPACITY TG

3 GN1/1

3 600x400

5 GN1/1

5 600x400

7 GN1/1

7 600x400

10 GN1/1

10 600x400

10 GN1/1

10 600x400

15 GN1/1

15 600x400

20 GN1/1

20 600x400

SPACE BETWEEN TRAYS cm 7 7 10,5 7 7 7 7

BLAST CHILLING PERFORMANCE

+3°C 15 kg 23 Kg 25 Kg 25 Kg 35 Kg 45 Kg 60 Kg

BLAST FREEZING PERFORMANCE

-18°C 9 kg 12 Kg 15 Kg 15 Kg 20 Kg 25 Kg 35 Kg

GAS GAS R452A/R507A R452A/R507A R452A/R507A R452A/R507A R452A/R507A R507 R507

TEST DETAIlS °C / RH +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65% +43 / 65%

ABSORBED POWER W 40 50 65 65 65 70 85

POWER SUPPLY V-P-Hz 220/240-1-50 220/240-1-50 220/240-1-50 220/240-1-50 220/240-1-50

380V-3P-N-50Hz 380V-3P-N-50Hz

Available with racks kit and guides to fit pans 600x400mm or GN 1/1.

The external and internal structure is made of stainless steel. While the motor compartment is made of zinc-coated

metal sheet. The basin is insulated with expanded polyurethane resin with a density of 40Kg./Mc.

The power supply is possible thanks to electric cable with plug already provided by the manufacturer.

The insulation of the basin is free of CFC in order to guarantee a low environmental impact.

ATTENTION

All the operations regarding chapters:

“1 POSITIONING OF THE BLAST CHILLER/FREEZER” Pag. 28 - “2 ELECTRICAL CONNECTION AND EARTHING” Pag. 30 - “3

CLEANING” Pag. 32 - “4 RECOMMENDATIONS AND WARNINGS” Pag. 33 - “7 MAINTANANCE - GARBAGE MANAGEMENT

- DISPOSAL OF MATERIALS” Pag. 44.

Must be carried out by high qualified technical staff.

Loading...

Loading...