Workman 1100/2100/2110 Page 2 – 7 Product Records and Maintenance

Lubrication

Note: Perform this maintenance procedure at the in-

terval specified in the WORKMAN Maintenance

Schedule. Lubricate more frequently when using this

vehicle for heavy duty operations and after each wash-

ing.

Grease Fitting Locations

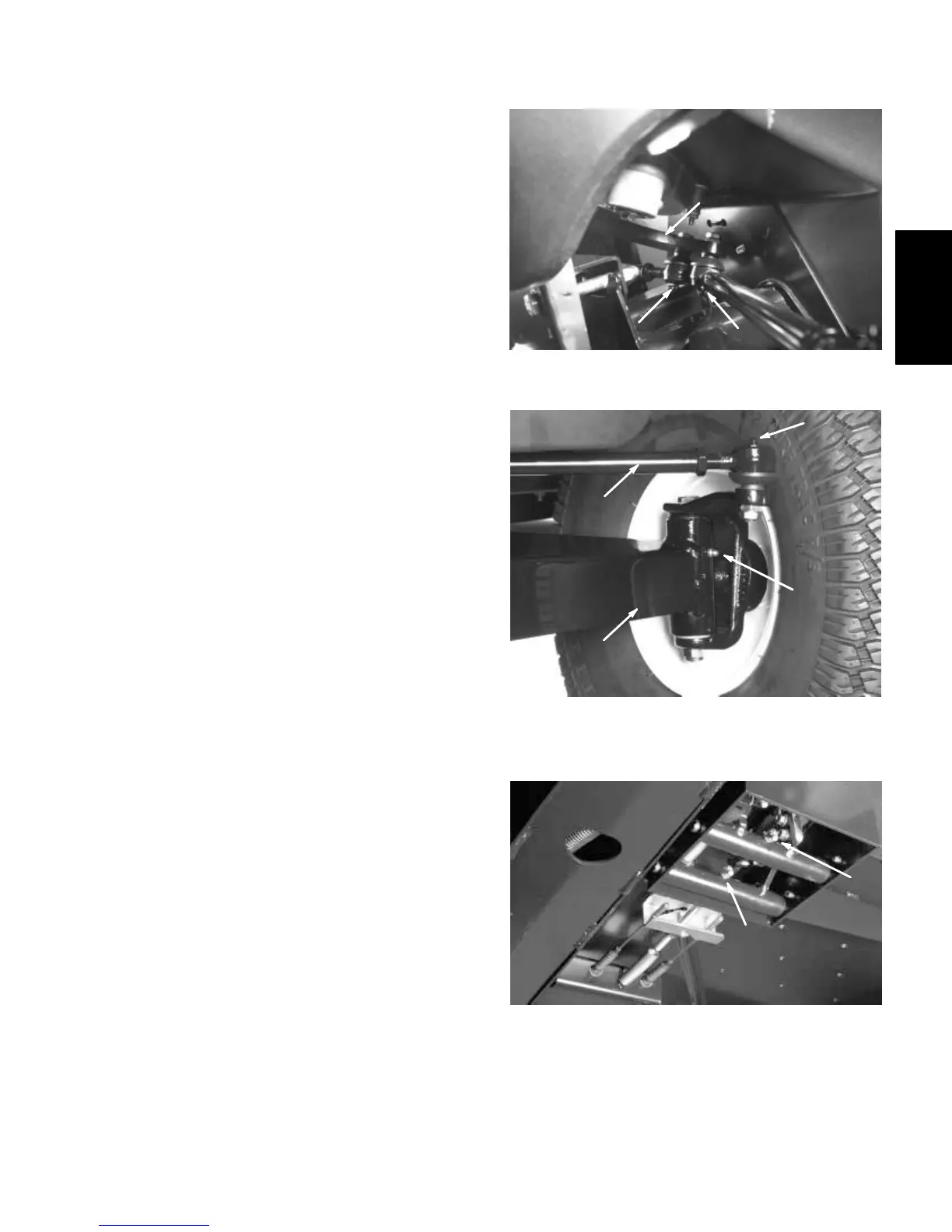

1. Each tie rod has a grease fitting on each ball joint, the

one that secures the tie rod to the Pitman arm (Fig 3) and

the joint that secures the tie rod to the front wheel spindle

(Fig 4).

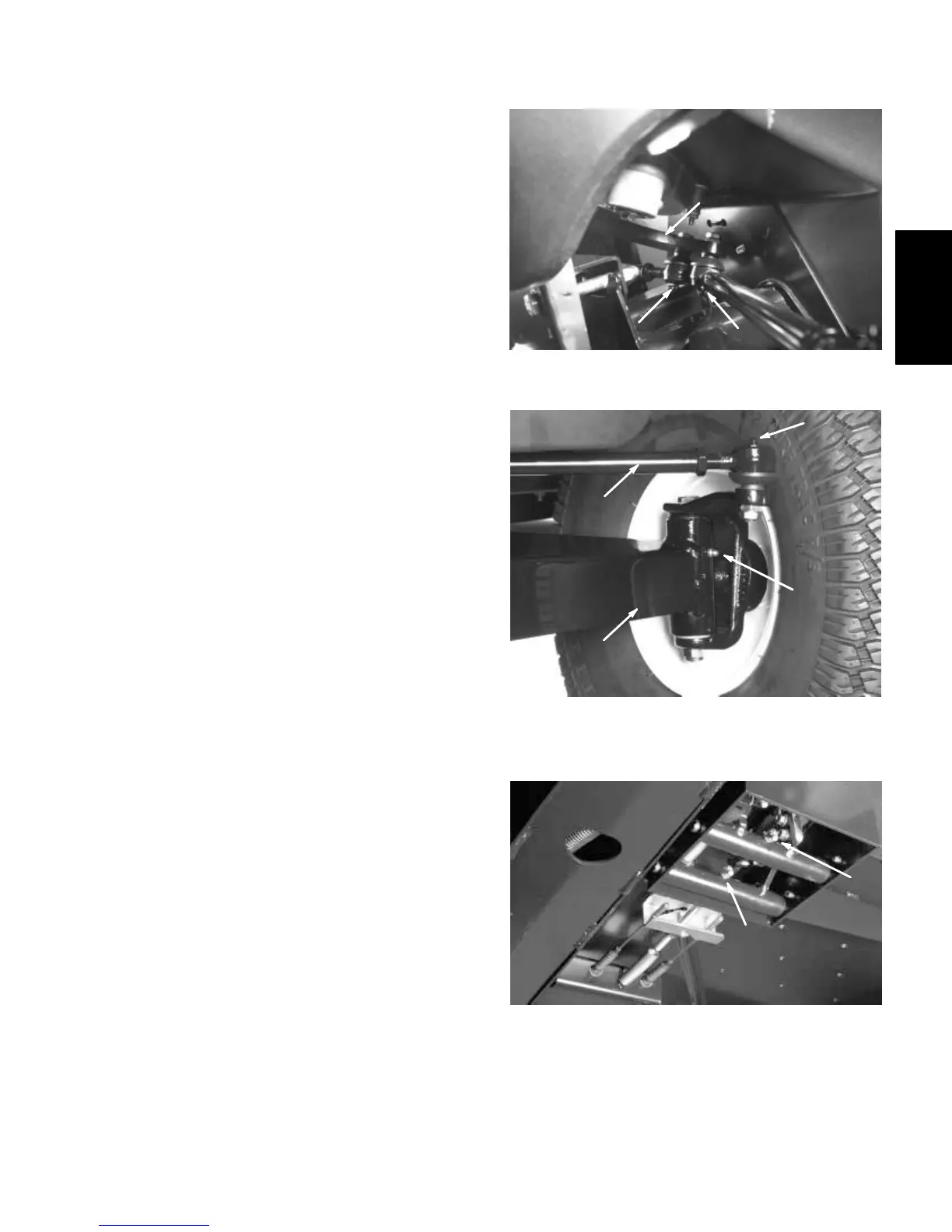

2. The A–arm has a grease fitting for the king pin (Fig

4).

3. The throttle and brake pedal pivots each have one

grease fitting. Note: These fittings are not greased at

the factory. Grease them only when and if the pedals be-

gin to stick (Fig. 5).

Greasing

IMPORTANT: Use No. 2 general purpose lithium

base grease.

1. Wipe grease fitting clean so foreign matter cannot be

forced into the bearing or bushing.

2. Pump grease into the bearing or bushing.

3. Wipe off excess grease.

1. Pitman arm 2. Grease fitting

Figure 3

2

2

1

1. Tie rod

2. A–arm

3. Grease fitting

Figure 4

3

3

2

1

1. Grease fitting (brake) 2. Grease fitting (throttle)

Figure 5

2

1

Product Records

and Maintenance

Loading...

Loading...