Workman 2100/2110 Page 3 – 9 Briggs & Stratton Gasoline Engine

Service Drive Belt

Inspection

Note: Perform this maintenance procedure at the in-

terval specified in the Operator’s Manual or Chapter 2

– Product Records and Maintenance.

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Raise bed and support with prop rod (see Operator’s

Manual).

3. Put vehicle transmission in neutral (see Set Neutral

Lock Assembly in Chapter 1 – Safety).

4. Rotate and inspect belt for excessive wear or dam-

age. Replace as necessary.

Replacement

1. Rotate and route belt over the driven clutch. Remove

belt from the drive clutch.

2. Place new belt around drive clutch. Rotate driven

clutch while routing the belt on.

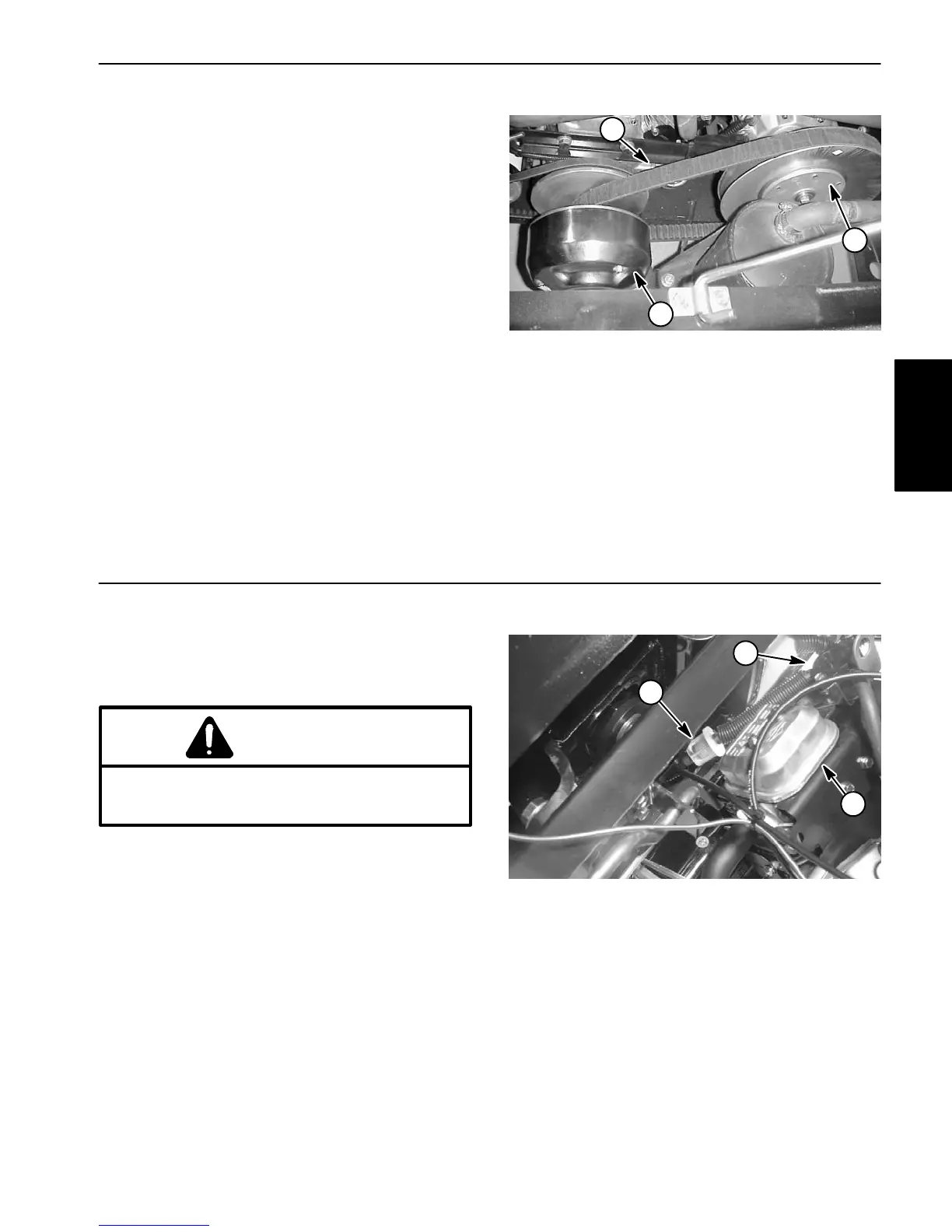

Figure 10

1. Drive belt

2. Drive clutch

3. Driven clutch

3

1

2

Replace Fuel Filter

Note: Perform this maintenance procedure at the in-

terval specified in the Operator’s Manual or Chapter 2

– Product Records and Maintenance.

WARNING

Use caution when working with fuel system com-

ponents (see Fill Fuel Tank and Fuel Safety Pre-

cautions).

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Raise bed and support with prop rod (see Operator’s

Manual).

3. Place a clean container under fuel filter.

4. Remove clamps securing fuel filter to fuel lines.

5. Remove fuel lines from fuel filter.

IMPORTANT: Mount filter so the arrow points in the di-

rection of fuel flow to the fuel pump.

6. Install new fuel filter to fuel lines with clamps pre-

viously removed.

Figure 11

1. Fuel filter

2. Rear cylinder head

3. Fuel pump

3

1

2

Briggs & Stratton

Gasoline Engine