Workman 2100/2110Page 3 – 12Briggs & Stratton Gasoline Engine

Muffler

Removal

1. Park machine on a level surface, stop the engine, en-

gage parking brake, and remove the key from the igni-

tion switch.

2. Raise bed and support with prop rod.

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow engine and exhaust

system to cool before working on the muffler.

3. Remove two coupler springs securing the exhaust

coupler to the muffler.

4. Remove two flange screws securing the muffler to

the frame.

5. Separate muffler carefully from the frame and ex-

haust coupler. Remove muffler from machine.

6. If manifold needs to be removed from engine, re-

move socket head screws and lock washers securing

the exhaust manifold to the engine.

7. Remove exhaust manifold with coupler and exhaust

gaskets from engine.

Installation

1. Make sure engine is off.

Note: Mount all fasteners before securing tightly to

ensure a proper fit of exhaust system.

2. If the exhaust manifold was removed from engine,

install manifold to engine with new gaskets. Attach ex-

haust manifold loosely to the engine with fasteners.

3. Position muffler to the frame and exhaust coupler.

4. Carefully attach muffler to the exhaust coupler. Se-

cure muffler loosely to the frame bracket with two flange

head screws.

5. Install two coupler springs securing the muffler to the

coupler.

6. Tighten socket head screws that secure exhaust

manifold to the engine.

7. Tighten flange head screws that secure muffler to the

frame.

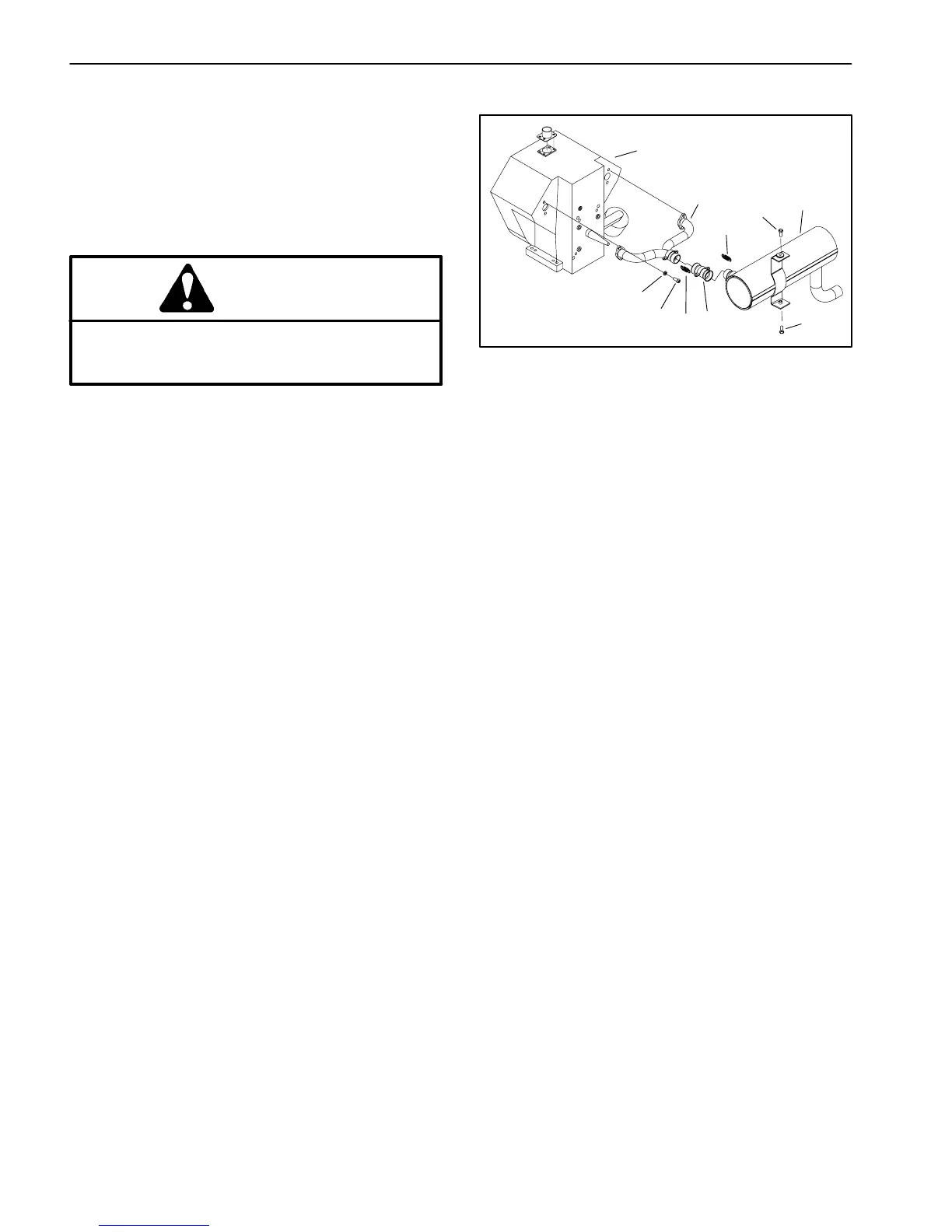

Figure 15

1. Engine

2. Muffler

3. Exhaust coupler

4. Coupler spring (4 used)

5. Exhaust manifold

6. Socket head screw

7. Lock washer

8. Flange head screw

1

7

6

2

5

4

3

4

8

8

Loading...

Loading...