Rev. B

Workman 2100/2110Page 3 – 6Briggs & Stratton Gasoline Engine

Adjustments

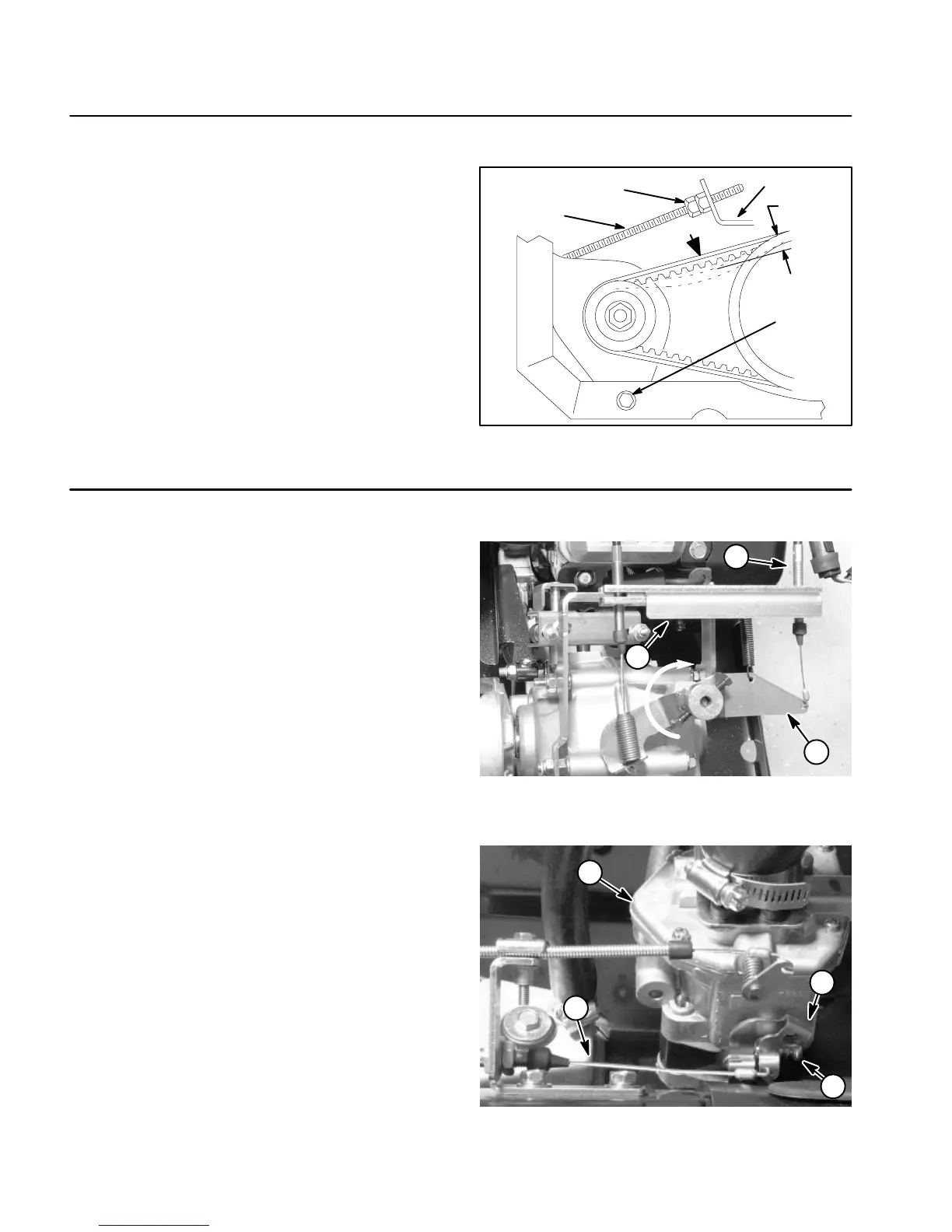

Adjust Starter/Generator Belt

Note: Perform this maintenance procedure at the in-

terval specified in the Operator’s Manual or Chapter 2

– Product Records and Maintenance.

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Loosen starter generator pivot bolt.

3. While pressing the belt at mid–span between the pul-

leys with 10 lb (44.5 N) of force, adjust jam nut on the

starter rod until the belt flexes 1/4 inch (6 mm).

4. Tighten starter generator pivot bolt.

Figure 4

1. Generator pivot bolt

2. Jam nut

3. Starter rod

4. Torque arm

1

2

10 lbs.

1/4”

3

4

Adjust Throttle Cable

Note: Workman 2100 and 2110 machines with Serial

Numbers above 240000000 are equipped with an en-

gine governor rather than a transaxle governor. Refer to

the Briggs & Stratton Repair Manual at the end of this

chapter for governor information on these machines.

Releasing the accelerator pedal should allow the throttle

cable to close the carburetor throttle control lever so that

the lever touches the adjustment screw. The adjustment

screw keeps the throttle valve inside the carburetor

open slightly to prevent the valve from binding.

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Lift cargo bed and prop with rod to gain access to the

engine.

3. Rotate governor arm on transaxle fully clockwise

(Fig. 5).

4. Make sure of the following:

A. The engine throttle control lever should be to the

fully open position (Fig. 6).

B. Adjust throttle cable at the cable bracket as nec-

essary, so there is no compression of the throttle

cable (Fig. 5). This will allow the throttle control lever

to fully close when the accelerator pedal is released.

Figure 5

1. Governor arm

2. Throttle cable

3. Cable bracket

3

1

2

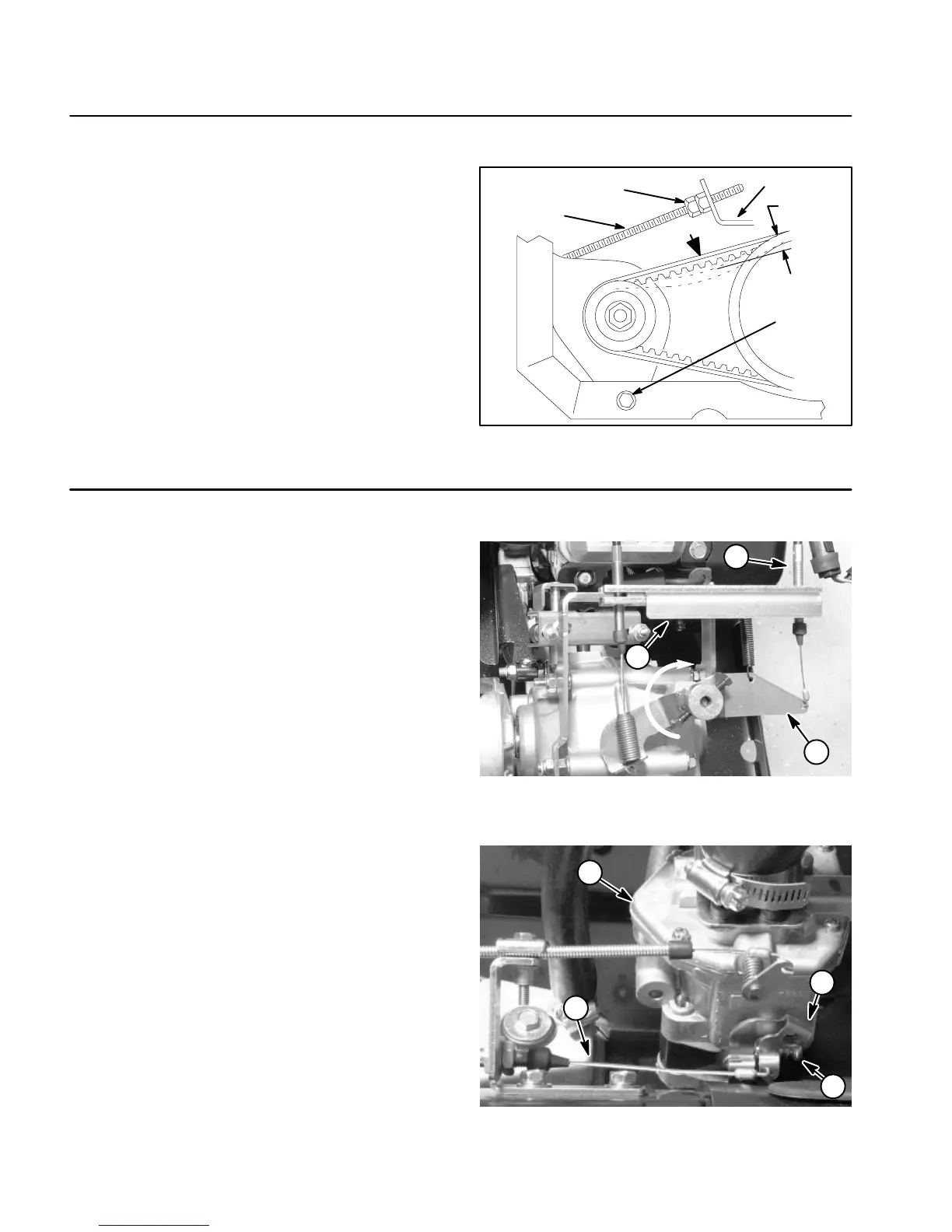

Figure 6

1. Carburetor

2. Throttle cable

3. Adjustment screw

4. Throttle control lever

3

1

2

4

Loading...

Loading...