(3)

Be sure that the gears rotate smoothly. Ad-

b) Apply grease to the outside of the (7) differential

just the backlash, if needed, with the

(5)

differ-

pinion shaft, and the (Ill differential side gear 14 (2

ential sidegearspacers so

it

is

within 0.004-0.008

PC~).

in. (0.1-0.2 mm).

(4)

Drive in the

(2)

differential lock pin through

the holes of the (1) differential housing and the

(7)

differential pinion shaft.

(5)

Put the (13) spiral ring gear 38 on the (1)

differential housing, and fasten with the

(9)

bolts

8

x

18 (8pcs).

(6)

To prevent the

(9)

bolts8

x

18 (8 pcs) from

loosening secure them with (10) wire 0.8

x

180.

c) Tightening torque for the

(9)

bolts 8

x

18: 17-22

ft-lbs (2.3-3 kg-m).

d) There me four kinds of (5) differential side gem

spacers:

i

0.035

in

(0.9 mm)

ii

0.039

in

(1.0 mm)

iii. 0.043 in

(1.1 mm)

iv.

-

0.047

in

(1.2 mm)

(7)

Fit the (4) ball bearings 6207 (2 pcs) on the

differential housing.

NOTES:

a) When performing step 2, be careful to line up the

shaft and liner hole carefully to prevent damage

ro the

(6)

differential pinion liner.

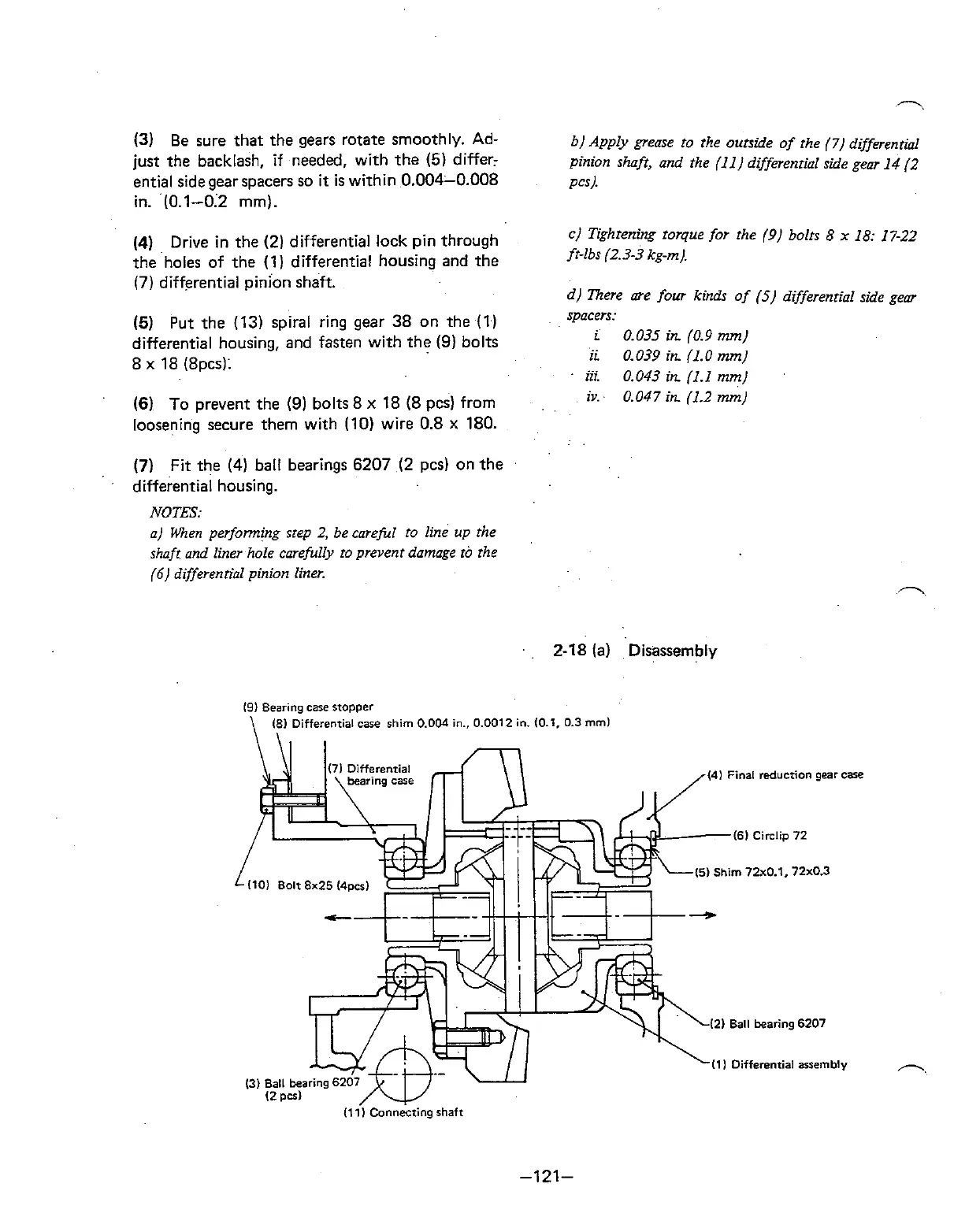

2-18 (a) Disassembly

19) Bearing case stopper

\

181 Differential case shim 0.004 in., 0.0012

in.

(0.1, 0.3 mml

141 Final reduction gear care

16) Circlip 72

151 Shim 72~0.1, 72~0.3

I101

Bolt

8x25 (4pcr)

121

Ball

bearing 6207

H

1

Differential assembly

llil

~onnkting shaft

-121-

Loading...

Loading...