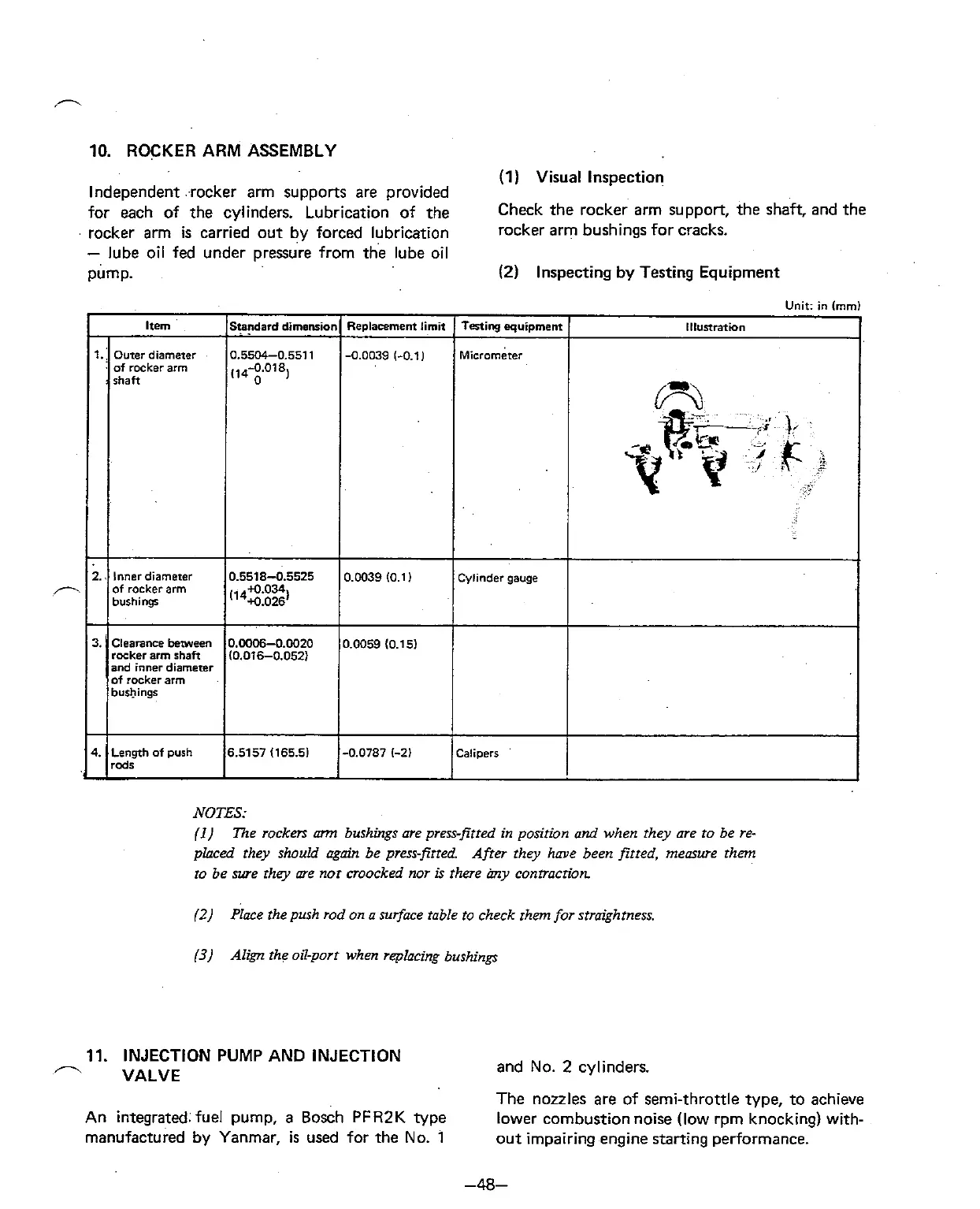

10. ROCKER ARM ASSEMBLY

(1) Visual Inspection

Independent rocker arm supports are provided

for each of the cylinders. Lubrication of the

Check the rocker arm support, the shaft, and the

rocker arm

is

carried out by forced lubrication

rocker arm bushings for cracks.

-

lube oil fed under pressure from the lube oil

pump.

(2)

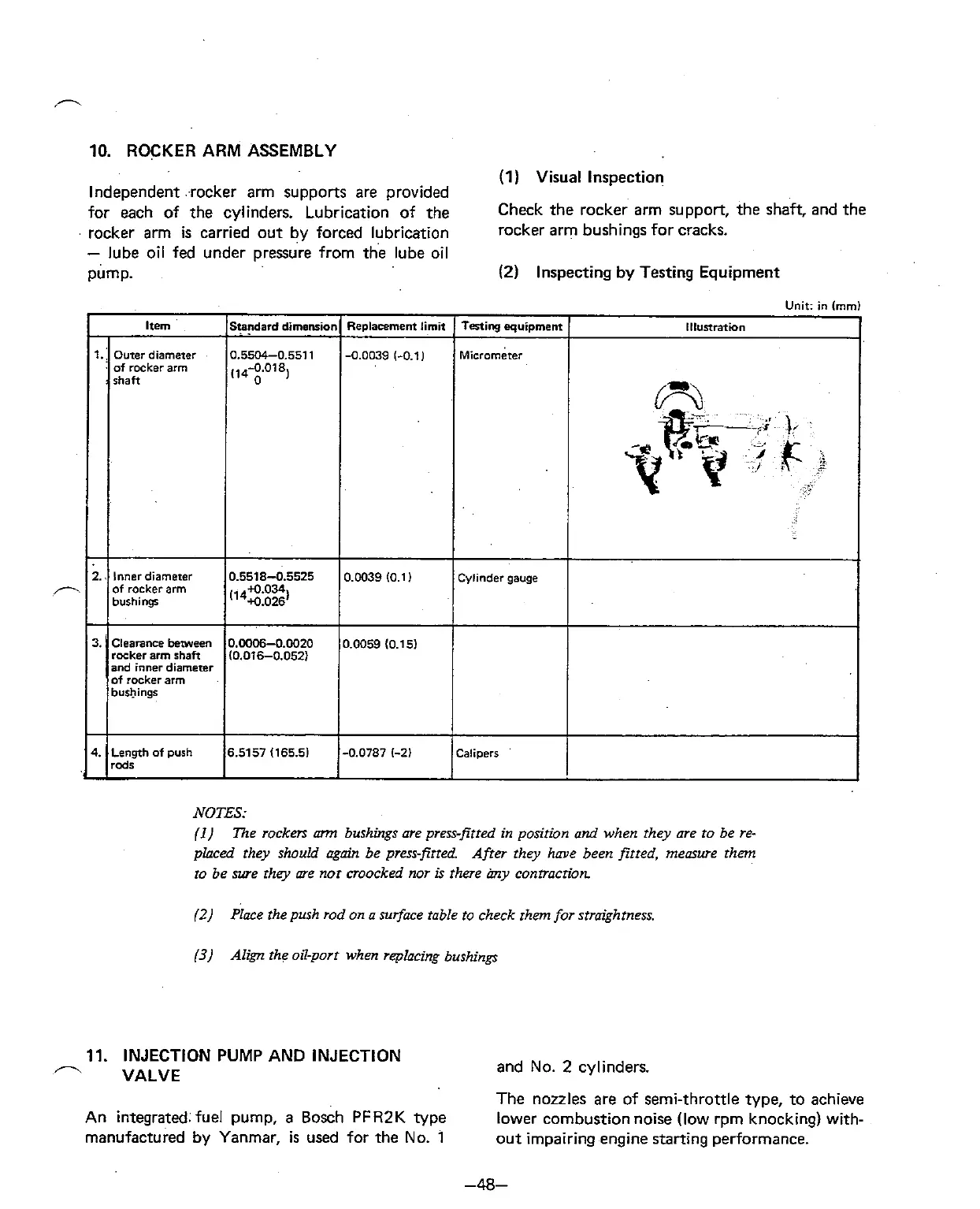

Inspecting by Testing Equipment

NOTES:

(I)

The rockers

am

bushings are press-fitted in position and when rhey are to be re-

placed rhey should again be press-firred. After they have been fitted, measure them

to be sure rhey me nor

noocked nor

is

there imy coniracrion

-

t

(2)

Place the push rod on a surface table to check rhem for straghmess.

(3)

Align the oil-port when replacing bushings

n

11.

INJECTION PUMP AND INJECTION

VALVE

1.:

i

2..

3.

4.

and No.

2

cylinders.

Standard

dimension

0.5504--0.5511

,14-0.018

0)

0.5518-0.5525

iQ.034

'14~.026'

0.OW6-0.0020

(0.016-0.052)

6.5157 (165.51

Item

Outer

diameter

of

rocker

arm

shaft

Inner

diameter

of

rocker

arm

bushing

Clearance

beween

rocker

arm

shaft

and

inner

diameter

of

rocker

arm

bushings

Length

of

push

rods

The nozzles are of semi-throttle type, to achieve

An

integrated.fuel pump, a Bosch

PFR2K

type

lower combustion noise (low rpm knocking)

with-

manufactured by Yanmar,

is

used for the No.

1

out impairing engine starting performance.

Replacement

limit

-0.0039 (-0.11

0.0039 10.1)

0.0059 (0.15)

-0.0787 (-2)

Teting

equipment

Micrometer

Cylinder

gauge

Calipers

Unit:

in

(mml

Illustration

.. .

Loading...

Loading...