8.

CYLINDER HEAD

(1)

Visual Inspection

A

cylinder head integrating two cylinders into

The

surface

of the head

is

checked

to

see

if

there

one and made by high precision quality casting

are any traces of coolant

or

gas

leakage. ~h~

in.

is

used.

side of the head is checked to ascertain that

it

is

Both the intake ports and the exhaust ports are

not clogged up anywhere by accumulated debris

integrated in the cylinder head, and overall engine

and that there

is

no corrosion.

design and construction has been simplified by

eliminating manifolds.

(2)

Inspecting

by

Testing Equipment

Item

90 degrees

1

2.

standsrd

dimemion

Intake:

0.2755-0.2761

(7+0.015)

+O

Exhaust:

0.2763-0.2775

!

(7+0.020

+0.050)

0.2736-0.2740

1

17-o.040

-0.050)

Intake:

0.~15-0.0025

(0.040-0.0651

Exhaust:

0,001 7-0.0027

(0.045--0.070)

0.0696 (1.771

-

-

1.4370 136.5)

Inner diameter

of

valve guider (after

assembly)

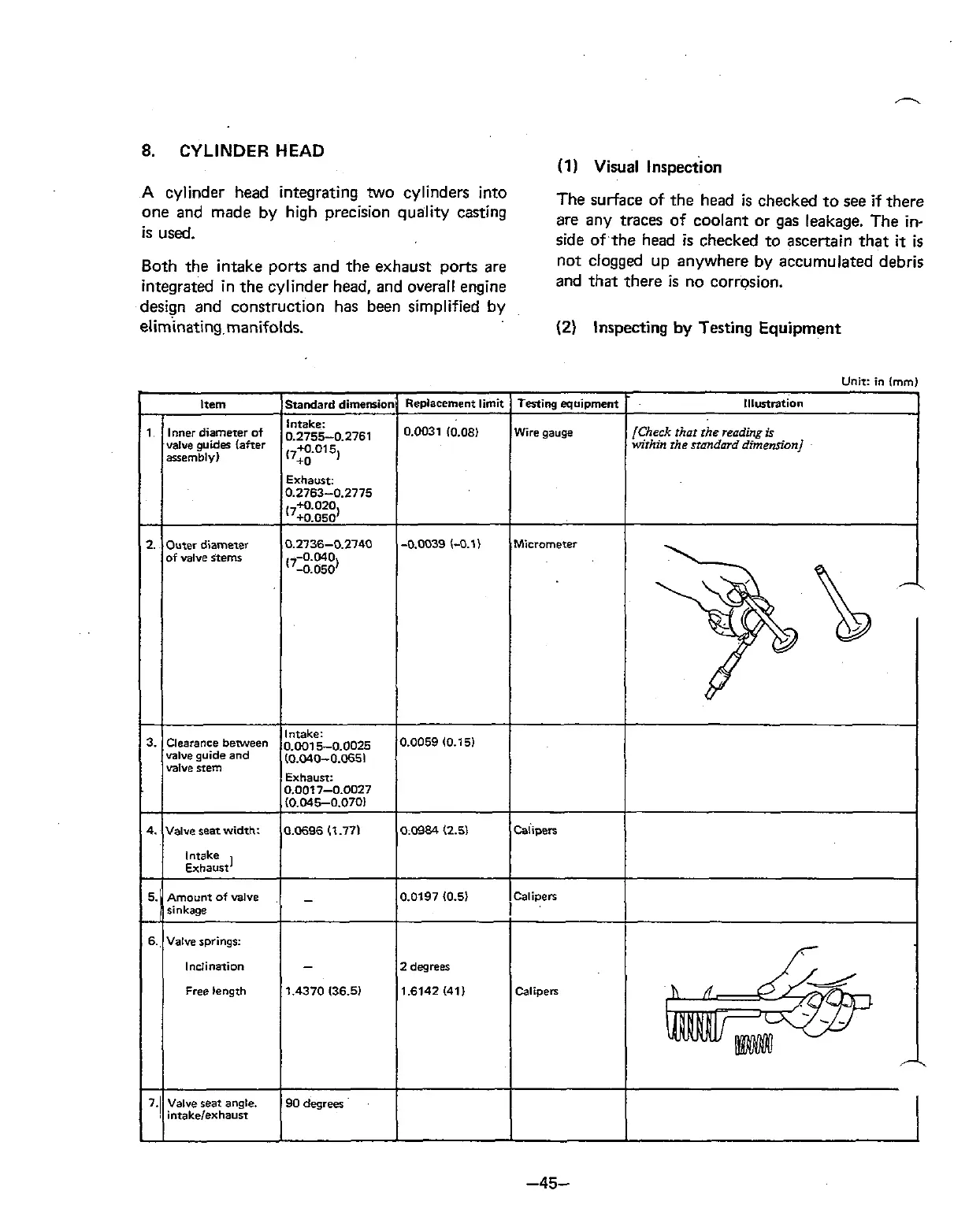

Outer

diameter

of valve Remr

Replacement limit

0.0031 (0.08)

-0.0039 (-0.1)

0.0059 10.151

0.0984 (2.5)

0.0197 (0.51

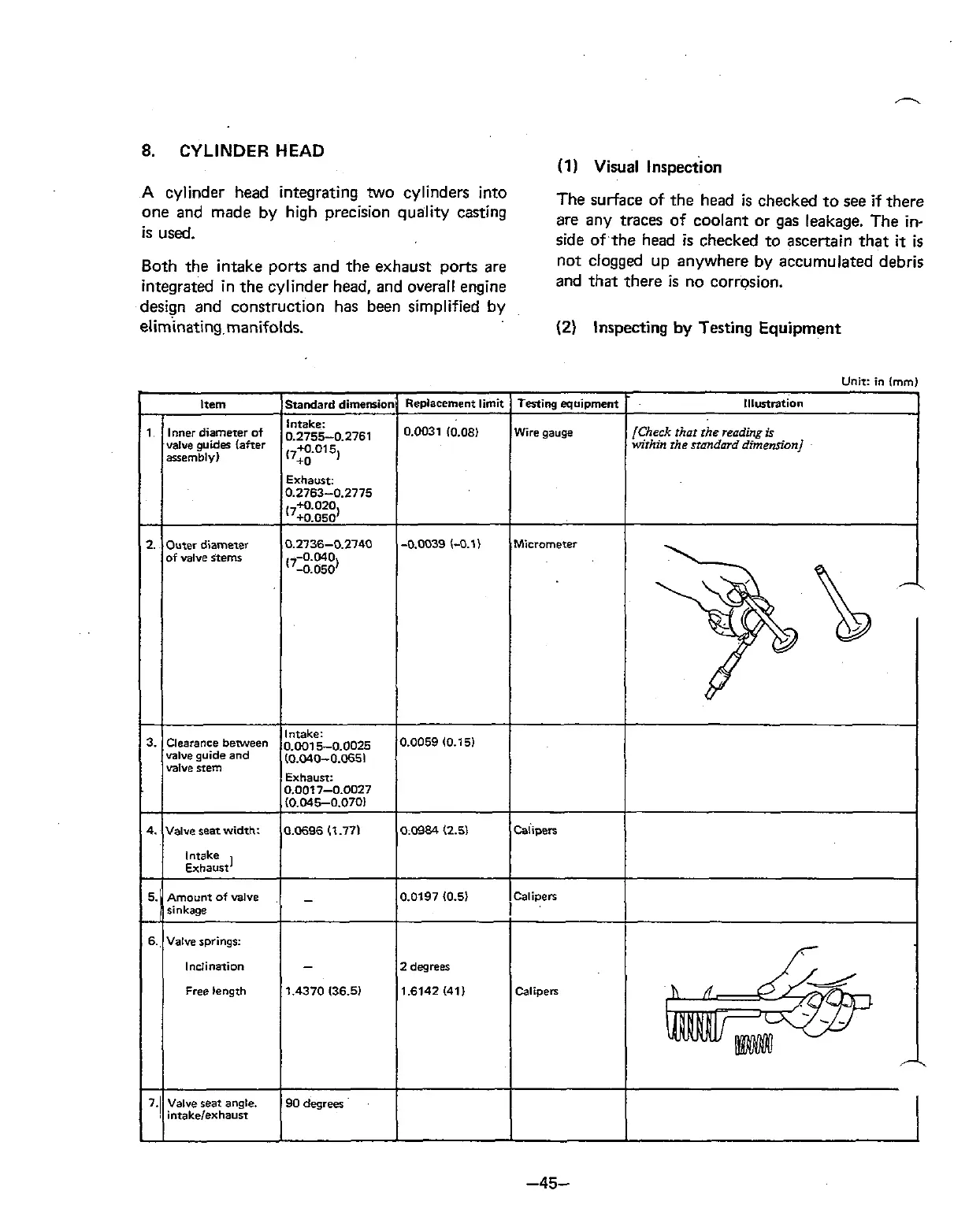

2 degrees

1.6142

(41)

Testing equipment

Wire gauge

Micrometer

Caiipen

lCalipen

Calipers

Unit:

in

(mm)

1

lllunmion

[Check thor rhe reading

is

wrhm the standard

dimension]

b-

3. Wearance

beween

valve guide and

valve stem

4.

Valve

seat width:

Intake

Exhaust

5.'

6.

Amount of

valve

sinkage

Valve springs:

Inclination

Free length

7.

!

Valve reat angle.

intakelexhaurt

Loading...

Loading...