(3)

Replacing theMain Bushing

Whenever the readings for the main bushings ex-

ceed the repairable limit, they must be replaced.

When fitting the main bushings in the main bush-

ings housing and cylinder block,

observe the fol-

lowing points:

a) To extract and insert bushings, always

use the bushings removing and installing tools.

b)

When inserting new bushings, be sure that

the oil passages are aligned.

C)

After the new bushings have been install-

ed, measure the inner diameter of the main

bushingto check that they are properly aligned,

and

not contracted.

7.

CAMSHAFT

A

single, integrated camshaft, incorporating the in-

take and exhaust cams, and the fuel cam,

is

used.

The fuel cam has straight flank and convex curves

while the intake and exhaust cams have parabolic

acceleration curves, in order to reduce the shock

of inertia force, this also serves to effectively

re

duce noise.

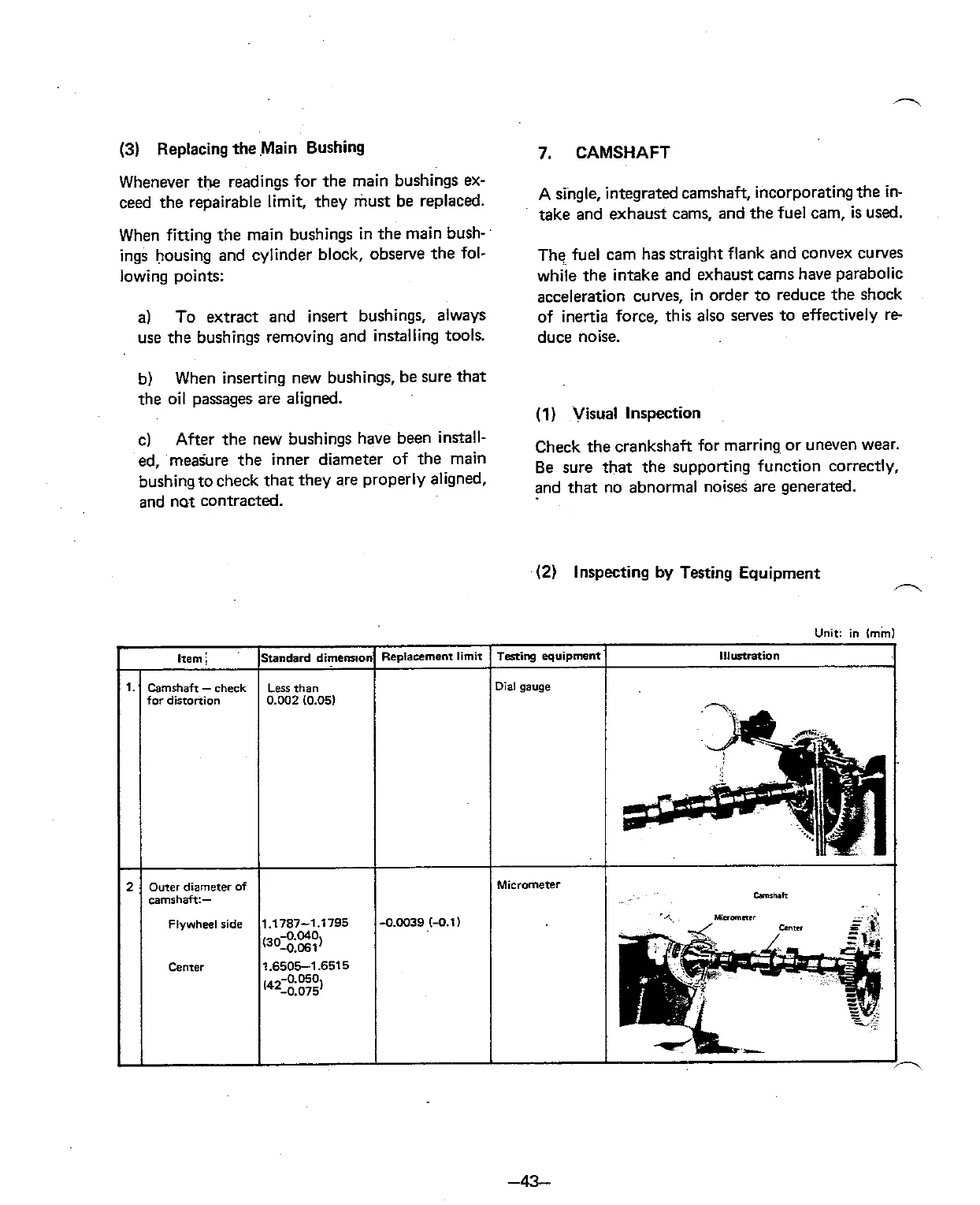

(1)

Visual Inspection

Check the crankshaft for marring or uneven wear.

Be sure that the supporting function correctly,

and that no abnormal noises are generated.

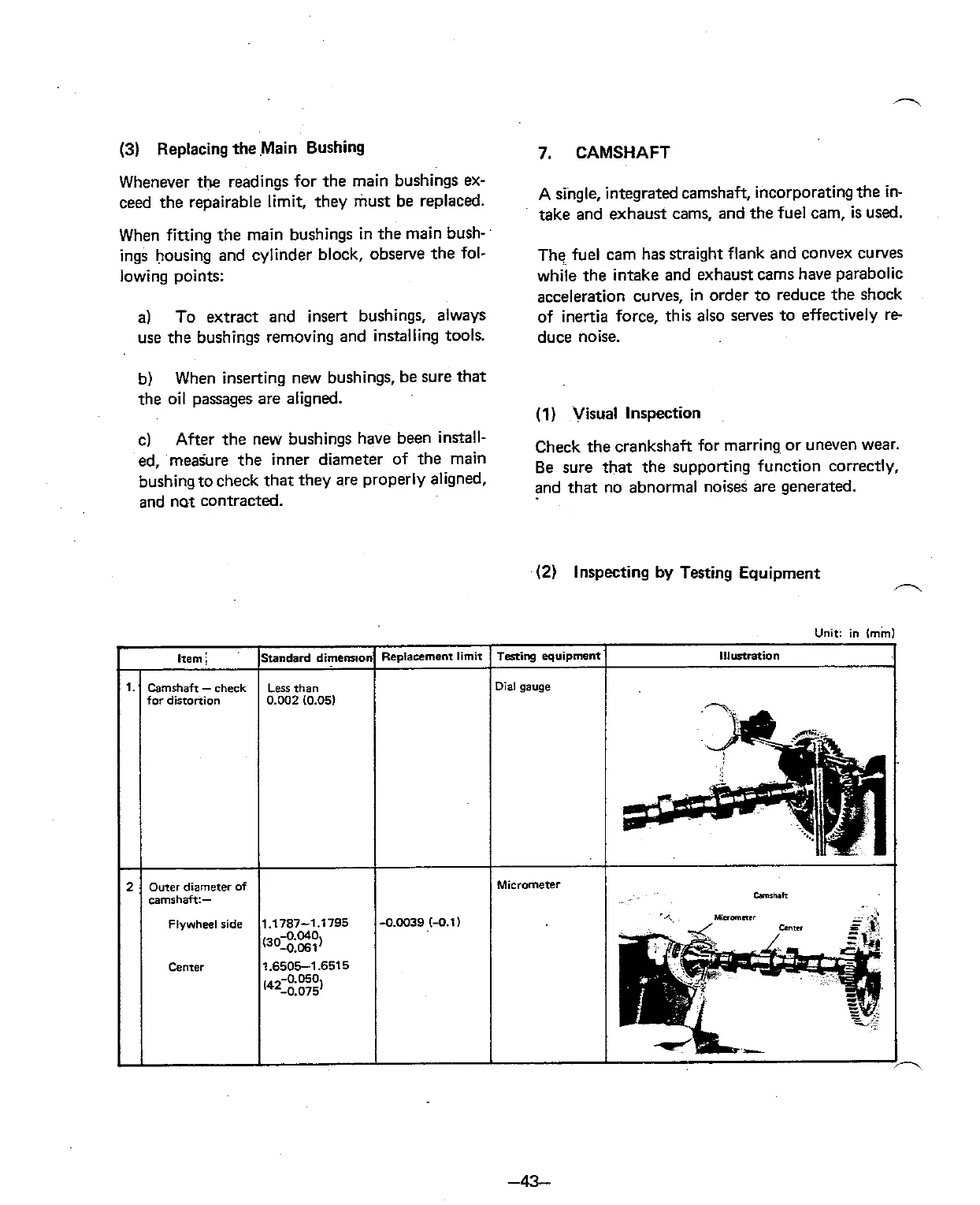

(2)

Inspecting

by

Testing Equipment

A

Unit:

in

imhl

for

distortion

1.6505--1.6515

Loading...

Loading...