16 UL Standards

YASKAWA TOEPC71061723A YASKAWA AC Drive CR700 Quick Start Guide 113

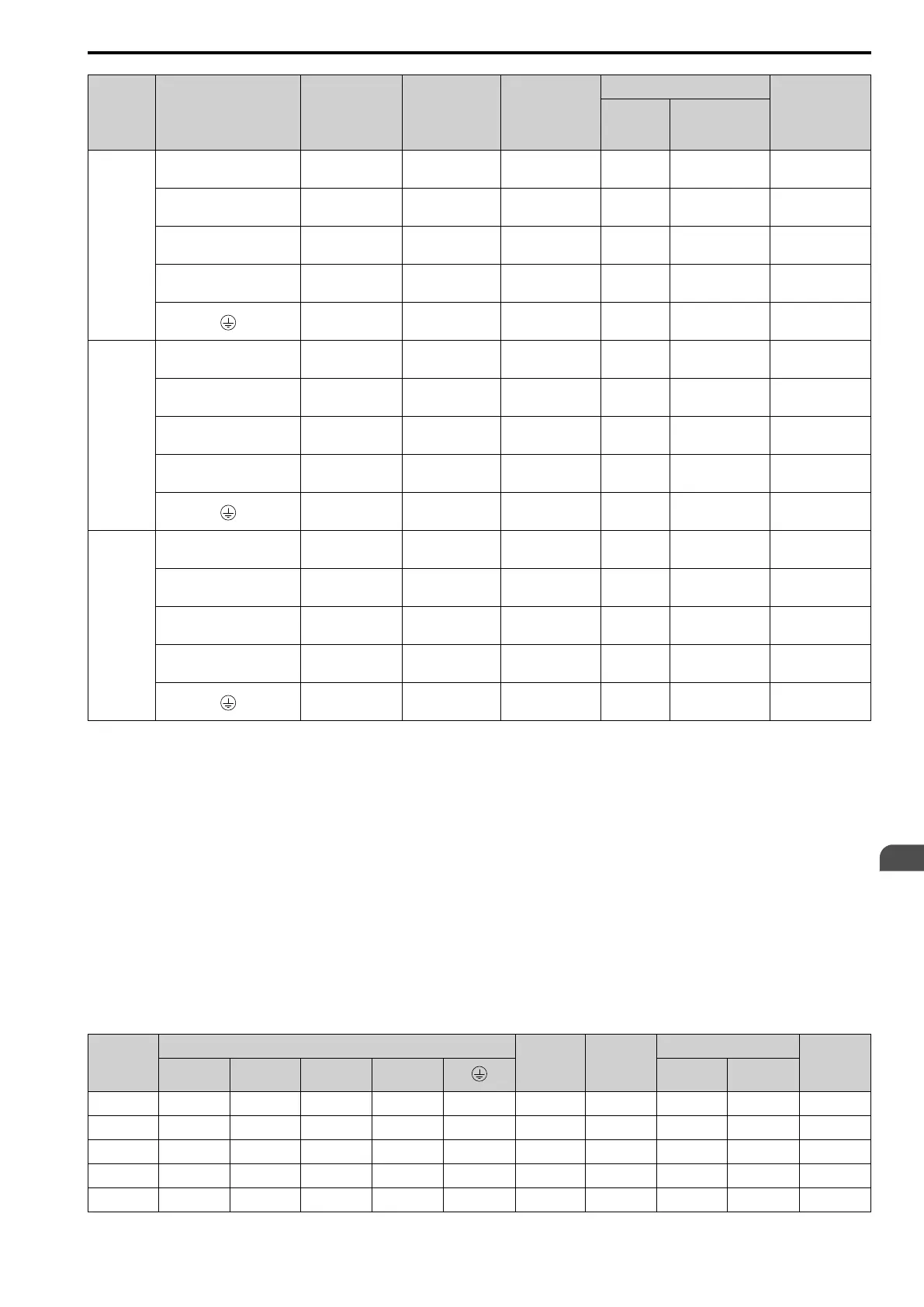

Model Terminal

Recomm. Gauge

AWG, kcmil

Applicable

Gauge

(IP20 Applicable

Gauge

*1

)

AWG, kcmil

Wire Stripping

Length

*2

mm

Terminal Screw

Tightening

Torque

N∙m (lbf∙in)

Size Shape

4414

R/L1, S/L2, T/L3, R1/L11, S1/

L21, T1/L31

250 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 4/0 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 4/0 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 3/0 × 4P

2 - 4/0

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

1/0

1/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

4453

R/L1, S/L2, T/L3, R1/L11, S1/

L21, T1/L31

250 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 4/0 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 300 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 3/0 × 4P

2 - 4/0 × 4P

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

2/0

2/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

4605

R/L1, S/L2, T/L3, R1/L11, S1/

L21, T1/L31

300 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

U/T1, V/T2, W/T3 300 × 4P

2/0 - 300 × 4P

(250 - 300 × 4P)

- M12 Hex self-locking nut

35

(310)

-, +1 400 × 4P

3/0 - 400 × 4P

(300 - 400 × 4P)

- M12 Hex self-locking nut

35

(310)

+3 4/0 × 4P

2 - 4/0 × 4P

(4/0 × 4P)

- M12 Hex self-locking nut

35

(310)

2/0

2/0 - 300

(-)

- M12 Hex bolt (slotted)

32 - 40

(283 - 354)

*1 For IP20 protection, use wires that are in the range of applicable gauges.

*2 Remove insulation from the ends of wires to expose the length of wire shown.

*3 For wire gauges more than AWG 8, tighten to a tightening torque of 4.1 N∙m to 4.5 N∙m (36 lbf∙in to 40 lbf∙in).

*4 Terminals - and +1 have two screws. The Recommended Gauge is the wire gauge for one terminal.

*5 A junction terminal is necessary to connect a braking resistor unit (LKEB-series) to terminals B1 and B2.

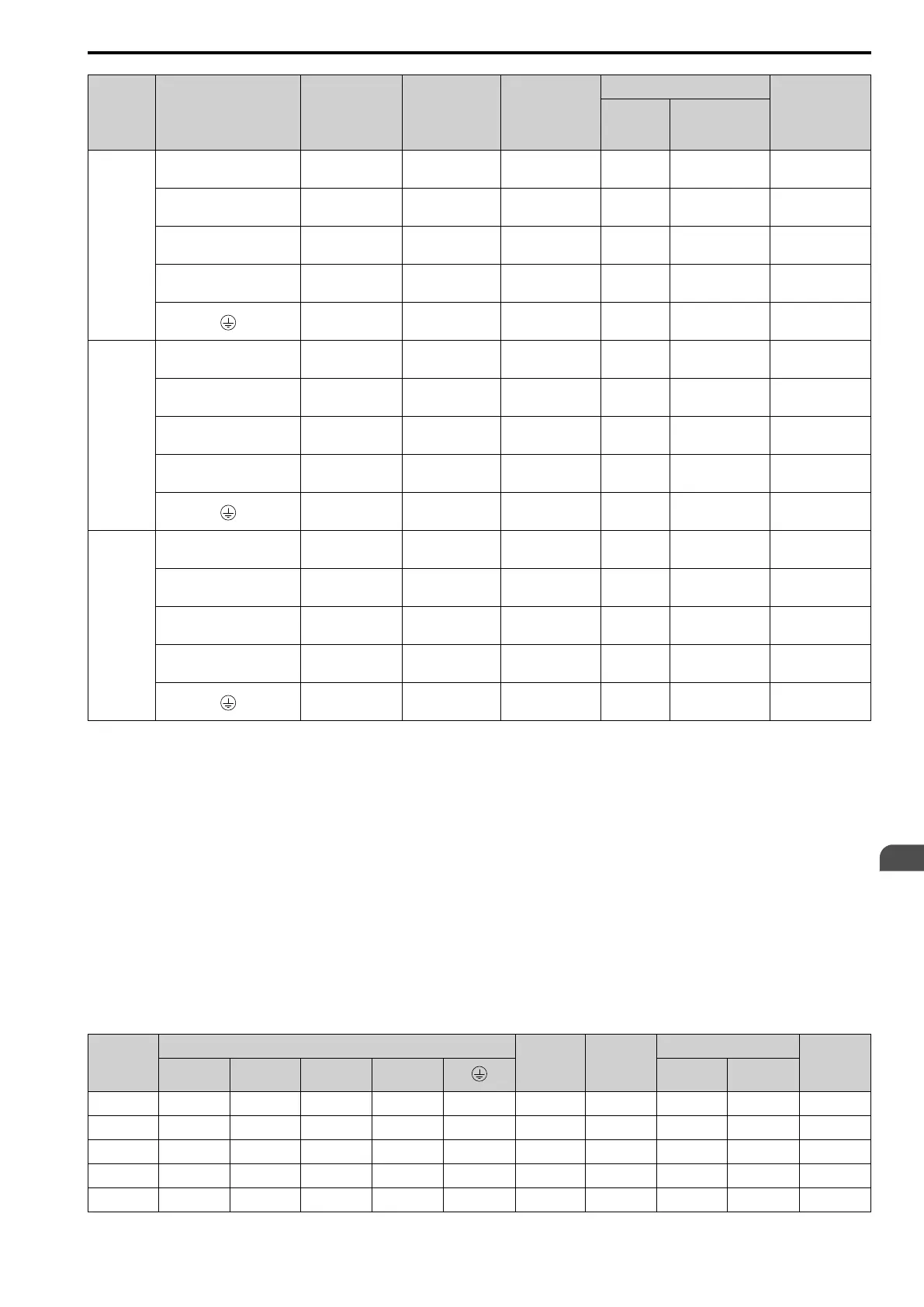

■ Closed-Loop Crimp Terminals

To comply with UL standards on drive models 2215 to 2415 and 4180 to 4605, use UL-approved closed-loop

crimp terminals. Use the tools recommend by the terminal manufacturer to crimp the closed-loop crimp terminal.

Yaskawa recommends closed-loop crimp terminals from JST Mfg. Co., Ltd. and insulation caps from Tokyo DIP

Co., Ltd. Contact Yaskawa or your nearest sales representative to make an order.

Refer to Table 16.4 to select crimp terminals as specified by drive model and wire gauge.

Note:

To comply with UL standards, use only insulated crimp terminals or crimp terminals with insulation tubing. Use UL-Listed, vinyl-

coated insulated copper wires for operation with a continuous maximum permitted temperature of 75 °C at 600 V.

Table 16.4 Closed-Loop Crimp Terminals and Insulation Caps

Model

Recomm. Gauge (AWG, kcmil)

Terminal

Screw Size

Crimp

Terminal

Model

Crimping Tool

Insulation

Cap Model

R/L1, S/L2,

T/L3

U/T1, V/T2,

W/T3

-, +1 +3 Tool Model Die Jaw

2003 - 2018 - - - - 10 M4 R5.5-4 YA-4 AD-900 TP-005

2025, 2033 - - - - 8 M5 R8-5 YA-4 AD-901 TP-008

2047 - - - - 6 M6 R14-6 YA-4 AD-902 TP-014

2060 - 2088 - - - - 6 M6 R14-6 YA-4 AD-902 TP-014

2115 - - - - 4 M6 R22-6 YA-5 AD-953 TP-022

EN

Loading...

Loading...