JOHNSON CONTROLS

62

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

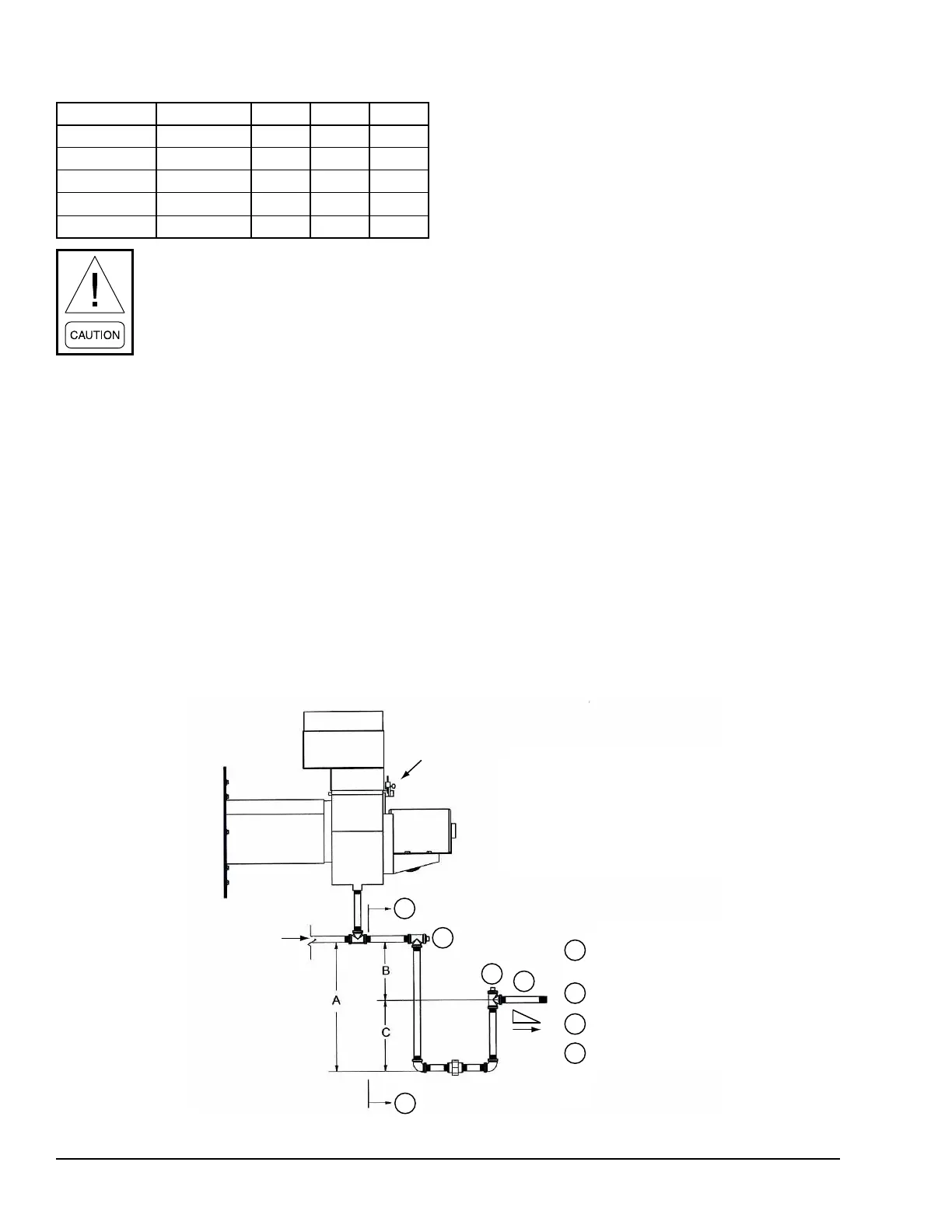

TABLE 2 - TSP AND DRAIN TRAP

MODEL DRAIN NPT A B C

DF-15/25 1/2 in. 4 in. 2 in. 2 in.

DF-30/50 1/2 in. 8 in. 4 in. 4 in.

DF-60/75 1 in. 8 in. 4 in. 4 in.

DF-85/200 1 in. 12 in. 6 in. 6 in.

DF-225/400 1 in. 16 in. 8 in. 8 in.

Failure to follow these instructions may

cause excessive condensation buildup,

resulting in water damage to the facility

and/or a cracked heat exchanger.

1. Observe local codes for gravity condensate drain-

age requirements.

2. Install the AHU at an elevation that enables prop-

er condensate drainage and trapping dimensions

as shown in Figure 97 on page 62. Minimum

trap dimensions MUST be accommodated.

3. The condensate drain line size must be the full

line size of the heat exchanger drain connection.

4. Drainlines,ttings,andsupportsshouldconform

to local codes, and be suitable for the application.

5. Condensate drain and trap discharge should be

pitched away from the equipment at a slope of 1/4

in. per linear foot or as local code dictates.

6. For outdoor or unconditioned space installations,

local climate may dictate the need to heat trace

and/or insulate the exposed drain lines and trap.

Frozen drain lines and/or trap will cause build up

of condensate inside the heat exchanger, resulting

in leakage and damage to the AHU, and possibly

to the building.

7. Provide unions in drain lines to allow removing

the trap for periodic cleaning of drain lines and the

trap. When the burner is operated at low capacity

for extended periods, more condensate is generat-

ed, and with it deposits of solids in the condensate

drainage system.

8. Provide the ability to prime the trap. During initial

and seasonal start-up, trap inspection and priming

is required. Condensate in the trap will evaporate

during long periods of non-use.

1

1

2

4

3

1

2

3

4

Foot

FIGURE 97 - GAS FURNACE CONDENSATE DRAIN TRAP

LD12912

BURNER ASSY

FLOW

PITCH

FIELD INSTALLED CONDENSATE

DRAIN PIPING - BY OTHERS

CLEAN OUT

WATER SEAL PRIME/ FILL

PITCH 1/4" / FOOT

ID

MOTOR

Loading...

Loading...