JOHNSON CONTROLS

18

FORM 160.84-N1

ISSUE DATE: 11/22/2016

SECTION 2 - RIGGING AND LIFTING

FORM 3 SHIPMENT

The chiller is shipped in five major assemblies:

• The evaporator/condenser shell assembly.

• The driveline (compressor/motor assembly).

• The Variable Speed Drive (VSD).

• The OptiView™ Control Center assembly.

• The Power Panel assembly.

• Miscellaneous shipped loose items.

One lifting chain is required for each

lifting point and each chain having a

working load limit 40% of condenser and

evaporator weight or heat exchanger be-

ing lifted.

The lifting chains traversing the evapora-

tor/condenser shells should remain 90°

+/- 10° from horizontal. A spreader bar

may be required to achieve the +/- 10°.

Refrigerant charges are shipped separately.

Arrangements with the local service ofce

must be made to ensure refrigerant is on-

site when the unit is ready to be charged.

When optional skids are used it may be

necessary to remove the skids so riggers

skates can be used under the unit end

sheets to reduce overall height.

Shells

1. Attach rigging chains to an adequate lifting device.

2. Attach chains to the lifting holes at the corner of

each end sheet as shown on Figure 5 on page 19.

3. If necessary to avoid contact with chiller compo-

nents install side spreader bars between the Evap-

orator and Condenser end sheet lifting chains.

4. The angle of the lifting chains traversing the en

sheet should not be less than 65° as shown on Fig-

ure 5 on page 19.

5. With an adequate lifting device lift the unit slight-

ly off the ground to determine adjustments neces-

sary to keep the unit level. Make adjustments as

necessary to level the unit.

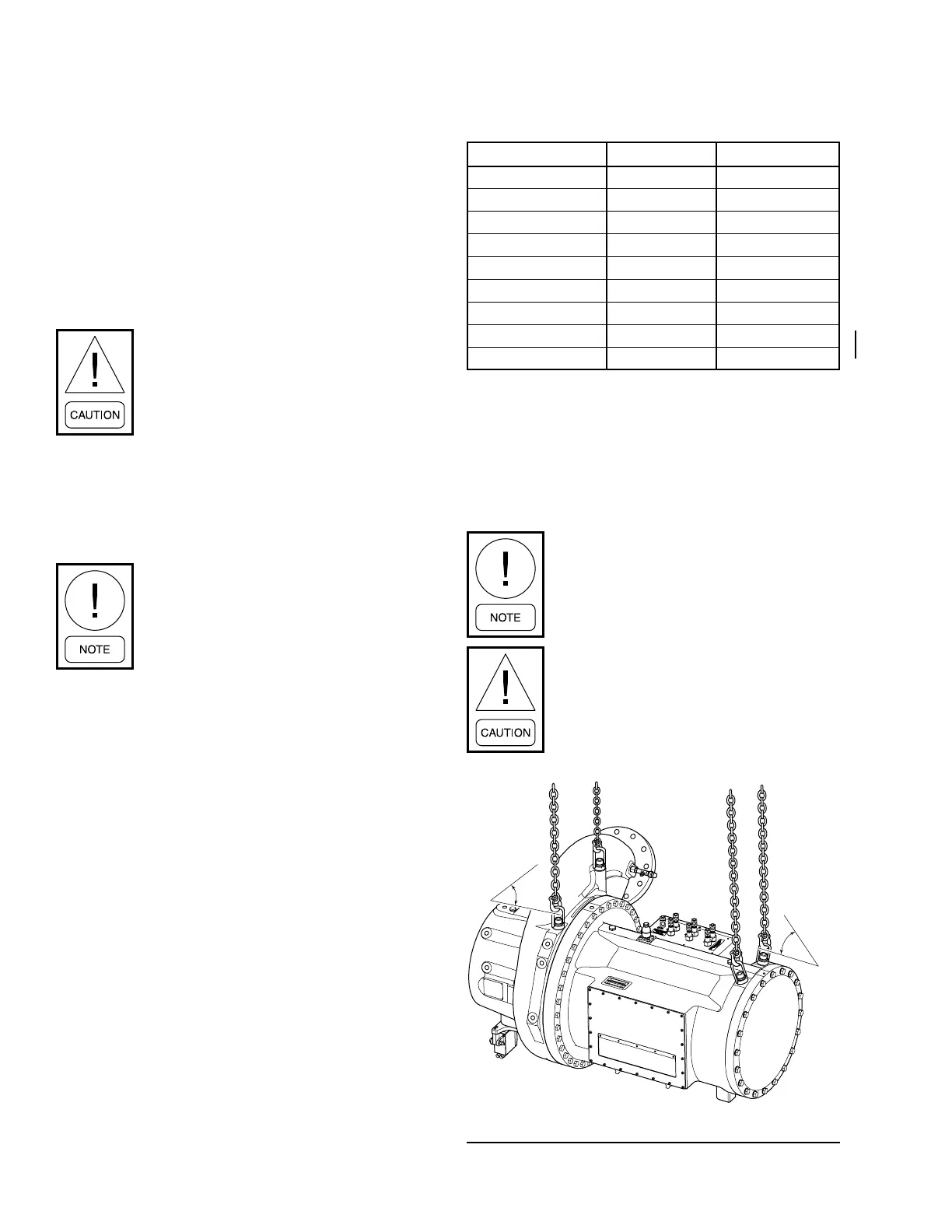

Compressor Motor Assembly

TABLE 1 - COMPRESSOR MOTOR WEIGHTS

Compr Code Pounds Kilograms

M2C-197FAC 2,861 1298

M2C-197FACD 2,861 1292

M2C-205FAC 2,867 1300

M2C-205FACD 2,867 1295

M2C-218FAC 2,987 1355

M2C-233FAC 2,999 1,360

M2C-246FAC 2,989 1,356

M6C-295FAC 4,298 1,950

M6C-331FAC 4,500 2,041

1. Attach rigging chains to each end of the com-

pressor/motor assembly as shown in Figure 4 on

page 18.

2. Lift the compressor/motor assembly off the

ground to check for center of gravity. Make ad-

justments as necessary.

The M2C and M6C Compressor/Motor

has metric lifting lugs

Use lifting chains with working load limit

each 70% of total driveline weight.

FIGURE 4 - DRIVELINE RIGGING

LD17276b

45°

Min.

45°

Min.

Loading...

Loading...