JOHNSON CONTROLS

52

FORM 160.84-N1

ISSUE DATE: 11/22/2016

SECTION 4 - REASSEMBLY

REFRIGERANT TUBING REASSEMBLY

The following is a step-by-step procedure to be used to

reassemble the chiller refrigerant piping.

Assembly of Straight Thread O-ring Port

Fittings

The male and female ends of SAE and ISO 6149

straight thread O-ring ports have UN/UNF or metric

straight threads. An elastomeric O-ring is fitted to the

male end. During assembly, the O-ring is firmly sand-

wiched between the angular sealing surface of the fe-

male port and the shoulder of the male end. Sealing is

thus affected and maintained by the O-ring compres-

sion which results from the clamping force generated

by tightening. The straight threads do NOT offer seal-

ing action; they provide the resistance (holding power)

for service pressure.

Adjustable End Assembly

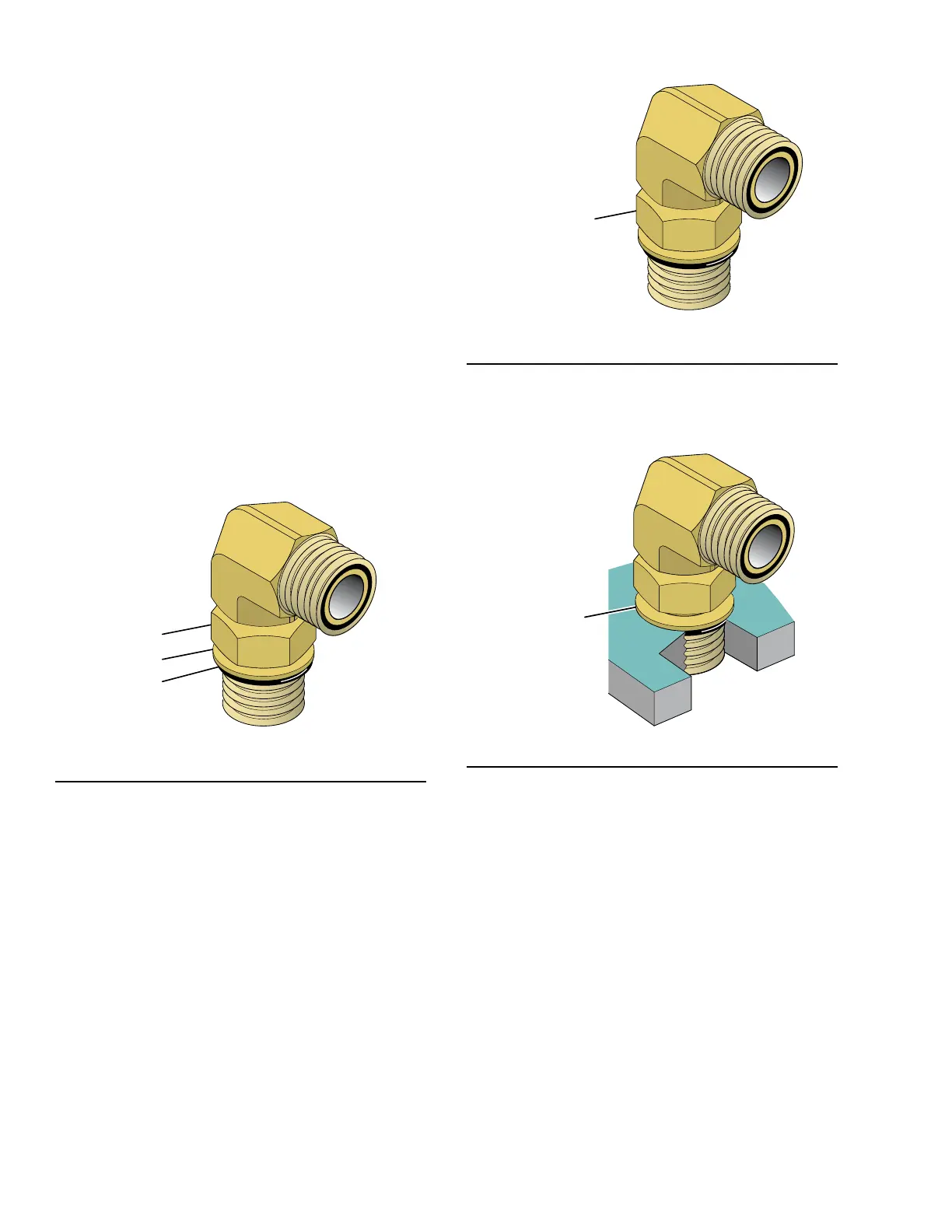

FIGURE 38 - ADJUSTABLE END FITTING

LD17269

LOCKNUT

O-RING

BACK-UP

WASHER

1. Inspect to ensure that both matching parts are free

of burrs, nicks, scratches or any foreign particles.

2. Install O-ring on port end of tting, if it is NOT

pre-installed, take care NOT to nick the O-ring.

3. Lubricate O-ring with a light coat of synthetic

Polyolester (POE) oil or POE grease.

4. Back off locknut as far as possible. Make sure

back-up washer is NOT loose and is pushed up

as far as possible. This ensures the O-ring is com-

pletely at the back of the land so it remains in the

land area when the tting is turned out at Step 6.

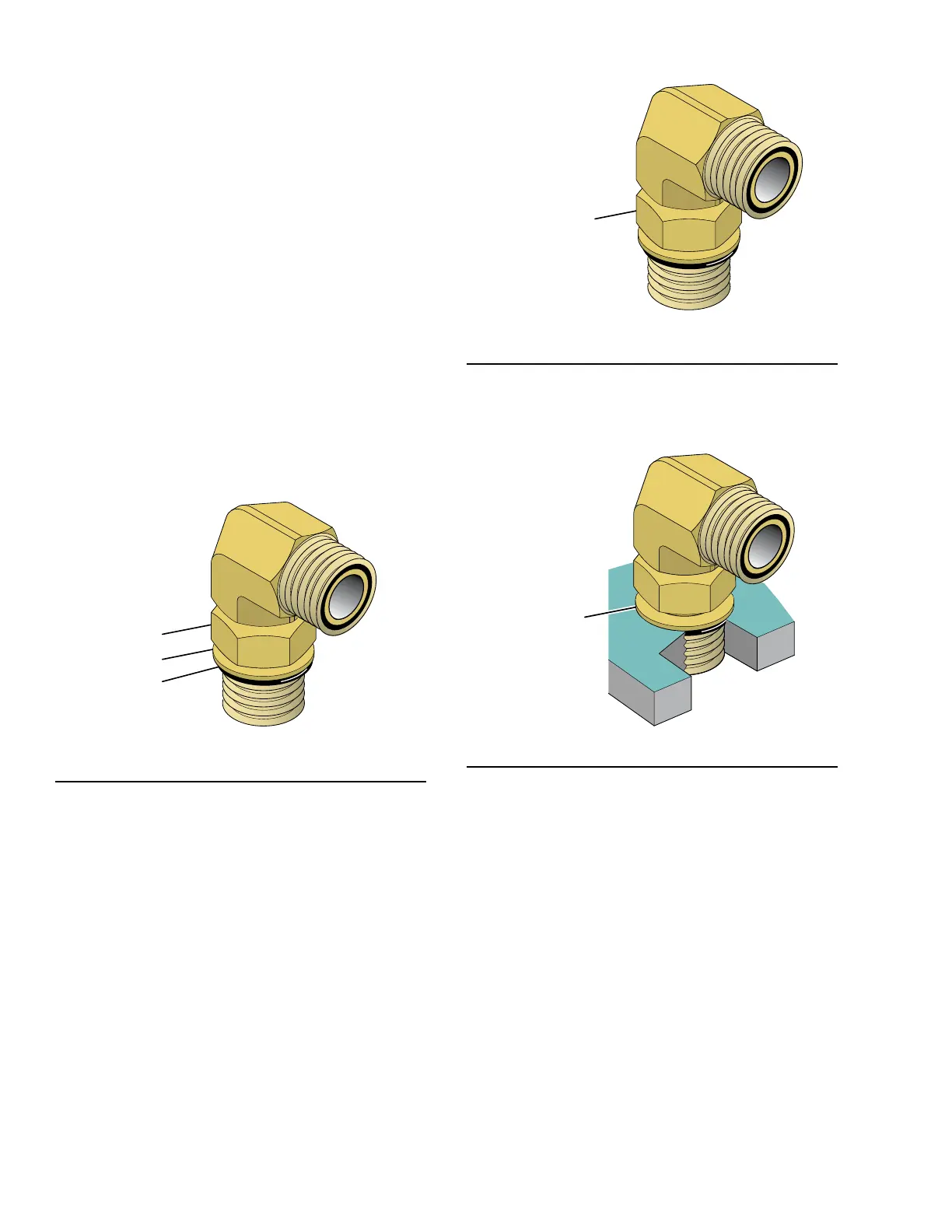

FIGURE 39 - BACK OFF LOCKNUT

LD17270

LOCKNUT

COMPLETELY

BACKED-UP

5. Screw tting into port until the back-up washer

contacts the face of the port. Light wrenching may

be necessary.

FIGURE 40 - SCREW FITTING INTO PORT

LD17271

BACK-UP

WASHER

CONTACTS

FACE

6. To align the tube end of tting to accept incom-

ing tube or hose assembly, unscrew by required

amount, but NOT more than one full turn. More

then one turn makes the locknut push the O-ring

into the machine threads beyond the tting land

area during step 7.

7. Using two wrenches, hold tting in desired posi-

tion and tighten locknut to the appropriate torque

value shown in Table 13 on page 42 or Table 12

on page 42.

8. Inspect to ensure that O-ring is NOT pinched and

the back-up washer seats at on face of port.

Loading...

Loading...