JOHNSON CONTROLS

26

FORM 160.84-N1

ISSUE DATE: 11/22/2016

SECTION 2 - RIGGING AND LIFTING

center of gravity. Make adjustments as necessary

to level the VSD.

3. Lift the VSD and remove all packing material, for

VSD weight refer to Table 10 on page 26.

4. Carefully lower the VSD on to the supports on the

condenser.

5. Fasten the VSD to the condenser and to the motor

terminal box duct. Remove the rigging chains.

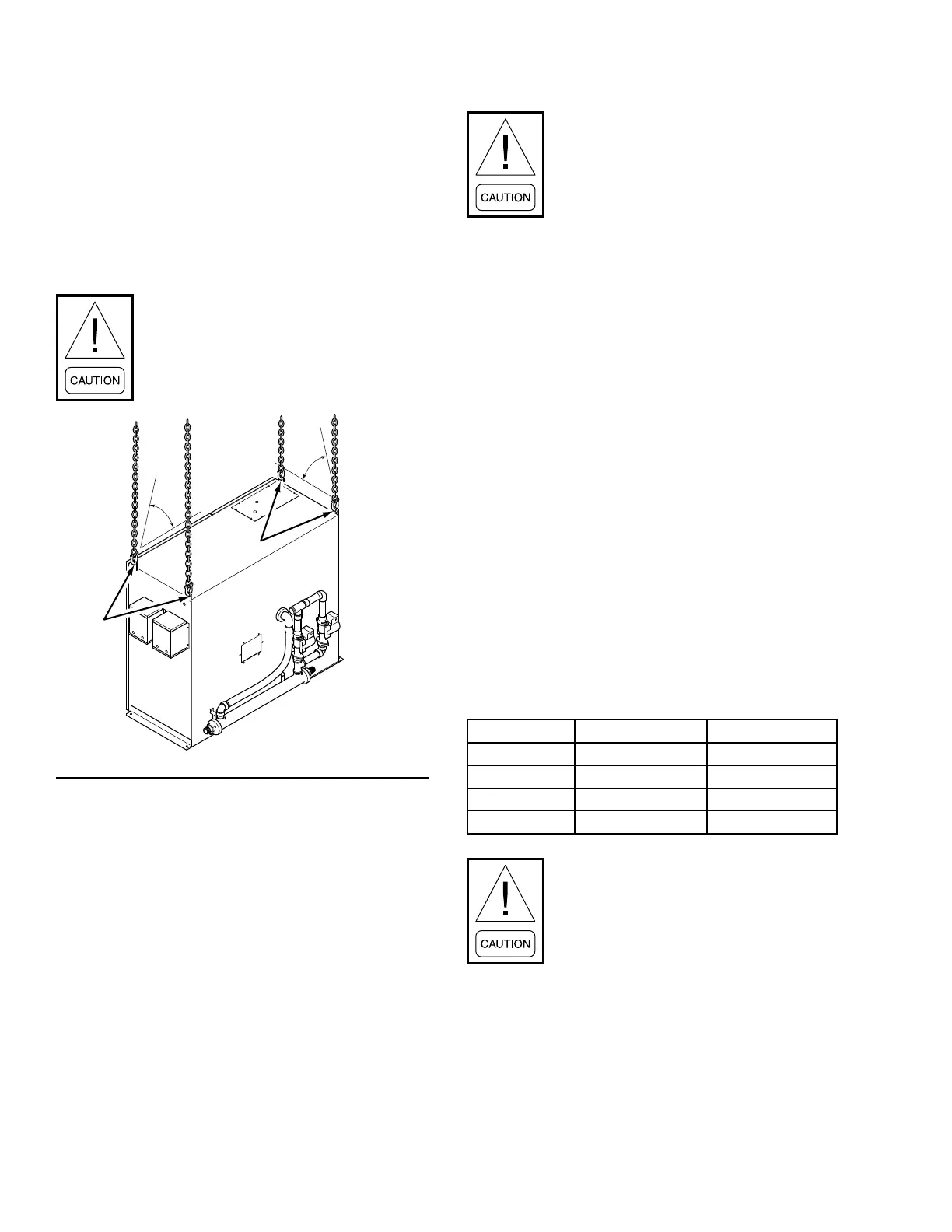

Use lifting chains with working load limit

each 35% of total VSD weight.

FIGURE 16 - VARIABLE SPEED DRIVE RIGGING

Holes

Lifting

Holes

65°

Min.

65°

Min.

FORM 10 SHIPMENT

The chiller is shipped in two assemblies:

• The chiller unit (less the VSD).

• The VSD.

• Miscellaneous shipped loose items.

The complete unit is factory leak-tested, evacuated,

and shipped charged with refrigerant.

The unit is first factory assembled, refrigerant piped,

wired and leak tested; then dismantled for shipment.

Evaporator/condenser is not skidded. All wiring inte-

gral with compressor is left on it, and all conduit is left

on shell.

Unit Rigging

One lifting chain is required for each lift-

ing point and each chain having a work-

ing load limit 30% of unit total weight or

heat exchanger being lifted.

The lifting chains traversing the evapora-

tor/condenser shells should remain 90°

+/- 10° from horizontal. A spreader bar

may be required to achieve the +/- 10°.

1. Attach rigging chains to an adequate lifting device.

2. Attach chains to the lifting holes at the corner

of each end sheet as shown on Figure 14 on

page 24.

3. If necessary to avoid contact with chiller compo-

nents install side spreader bars between the Evap-

orator and Condenser end sheet lifting chains.

4. The angle of the lifting chains traversing the en

sheet should not be less than 65° as shown on Fig-

ure 14 on page 24.

5. With an adequate lifting device lift the unit slight-

ly off the ground to determine adjustments neces-

sary to keep the unit level. Make adjustments as

necessary to level the unit.

Variable Speed Drive (VSD)

TABLE 10 - VARIABLE SPEED DRIVE WEIGHTS

Model Pounds Kilograms

HYP0490XH 1,226 556

HYP0612XH 1,954 886

HYP0774XH 2,060 934

HYP1278XH 3,806 1,727

The VSD is shipped with glycol in the

cooling system. The VSD coolant must

be changed to the inhibitor provided with

the shipped loose items prior to starting

the unit or a VSD over temperature fault

may occur.

1. Attach rigging chains from an adequate lifting de-

vice to the four lifting holes at the top of the VSD

as shown in Figure 17 on page 27.

2. Lift the VSD slightly off the ground to check for

center of gravity. Make adjustments as necessary

to level the VSD.

Loading...

Loading...