JOHNSON CONTROLS

50

FORM 160.84-N1

ISSUE DATE: 11/22/2016

SECTION 4 - REASSEMBLY

Form 11 Reassembly

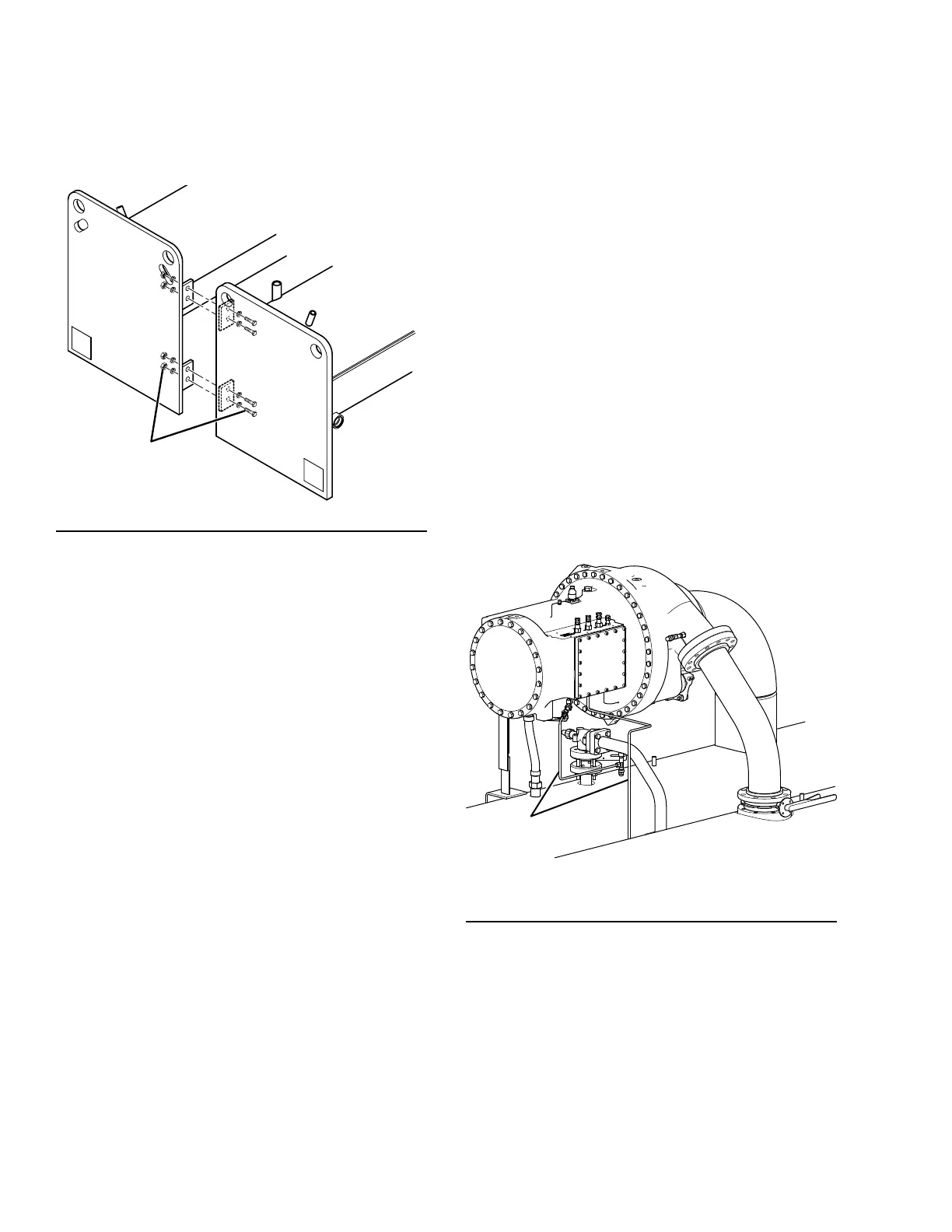

1. Bolt the tube sheets together as shown in Figure

35 on page 50. Note that the outside surfaces of

the tube sheets must be ush.

FIGURE 35 - SHELL REASSEMBLY

CONDENSER

5/8” x 2-1/2”

Bolts, Lockwashers,

and Hex Nuts

EVAPORATOR

LD14812

2. Assemble vibration isolators to unit. Refer Sec-

tion 3 - Installation on page 31.

3. Level shells in both directions. The longitudi-

nal alignment of the shell should be checked by

placing a level on the top of the shell, next to the

discharge connection. The transverse alignment

should be checked by placing a level on the tops

of both end sheets. Refer Section 3 - Installation

on page 31 for additional instructions to level

the unit. After shell is leveled, wedge and shim

each corner of the shell to solidly support it while

assembling the other parts.

4. Install the discharge piece and optional isolation

valve between the compressor and the condenser

using proper gaskets and hardware.

5. Complete the refrigerant liquid piping between

the evaporator and condenser. Be sure hardware

are all properly installed.

6. Tighten all hardware installed to the specied

torque values provided on Figure 37 on page 51.

7. The Variable Speed Drive will be shipped with

glycol in the cooling system. The Variable Speed

Drive coolant must be changed to the inhibitor

provided with the shipped loose items prior to

starting the unit or a VSD over temperature fault

may occur.

8. Re-connect motor power leads in the Variable

Speed Drive to T1, T2, and T3 terminals and

torque to 18-20 Ft-lbs. per the labels in the VSD.

9. Re-connect all unit wiring and harnesses (refer to

YMC

2

Unit Wiring and Field Control Modica-

tions (Form 160.84-PW2).

10. Install refrigerant piping (refer to Refrigerant Tub-

ing Reassembly section of this manual for proper

connection of O-ring ttings).

11. Pressure test the unit with nitrogen per Form

160.84-O1.

12. Remove Nitrogen and charge unit with refrigerant

(refer Form 160.84-OM1).

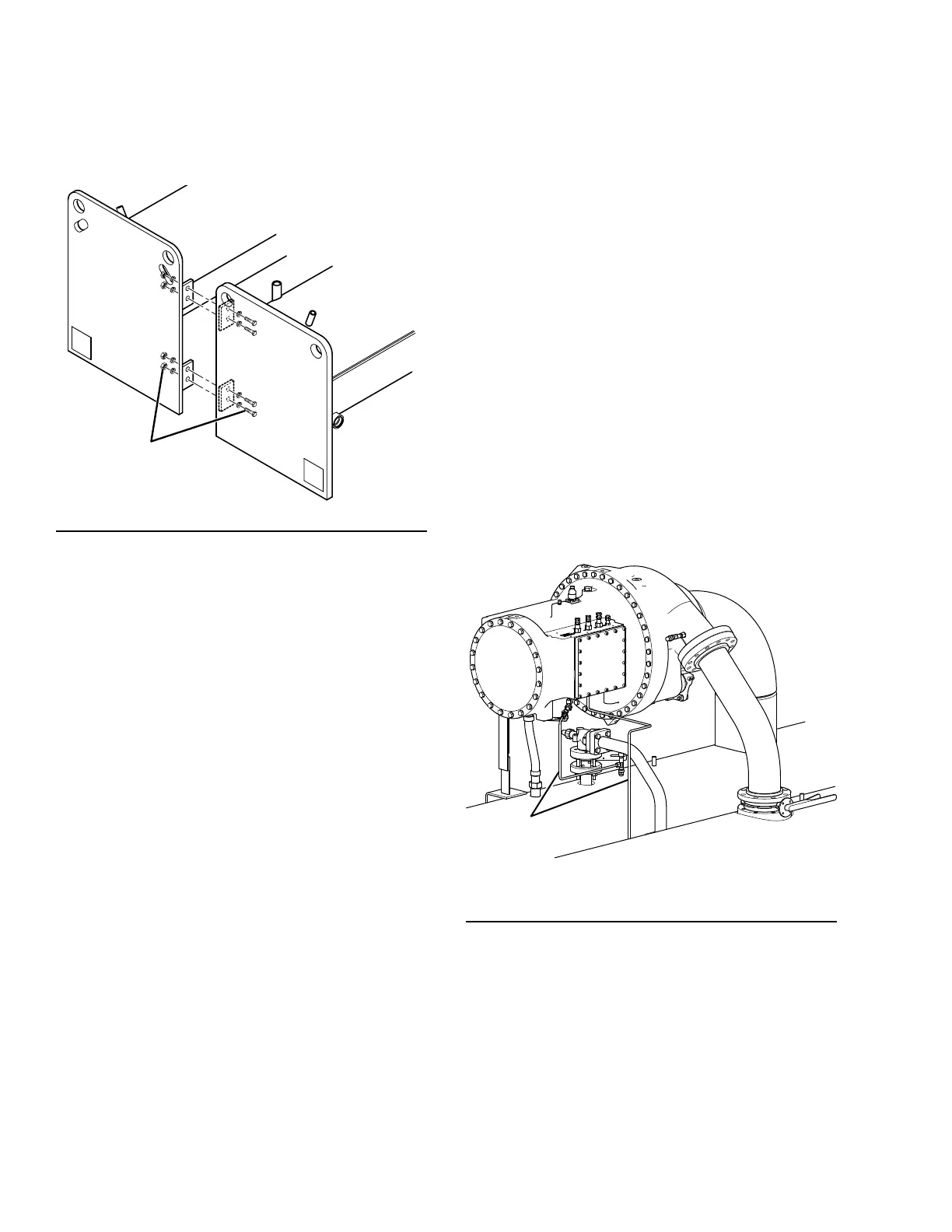

LD17280

3/8”

Steel

Piping

FIGURE 36 - REFRIGERANT PIPING

13. Complete installation and nally level the unit per

Installation Instruction. Refer Section 3 - Installa-

tion on page 31.

Loading...

Loading...